9Specifications

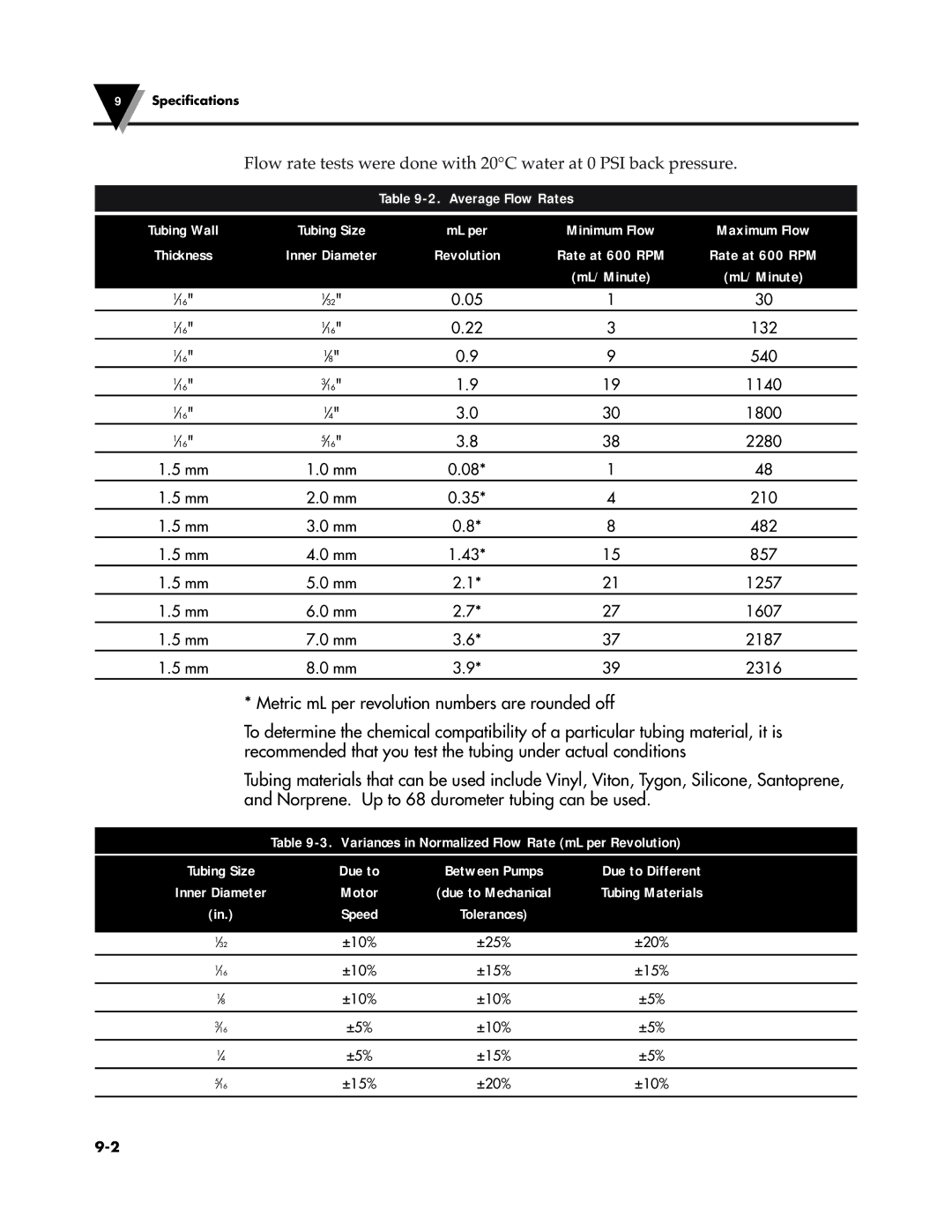

Flow rate tests were done with 20°C water at 0 PSI back pressure.

|

| Table |

| |

|

|

|

|

|

Tubing Wall | Tubing Size | mL per | Minimum Flow | Maximum Flow |

Thickness | Inner Diameter | Revolution | Rate at 600 RPM | Rate at 600 RPM |

|

|

| (mL/Minute) | (mL/Minute) |

1⁄16" | 1⁄32" | 0.05 | 1 | 30 |

1⁄16" | 1⁄16" | 0.22 | 3 | 132 |

1⁄16" | 1⁄8" | 0.9 | 9 | 540 |

1⁄16" | 3⁄16" | 1.9 | 19 | 1140 |

1⁄16" | 1⁄4" | 3.0 | 30 | 1800 |

1⁄16" | 5⁄16" | 3.8 | 38 | 2280 |

1.5 mm | 1.0 mm | 0.08* | 1 | 48 |

1.5 mm | 2.0 mm | 0.35* | 4 | 210 |

1.5 mm | 3.0 mm | 0.8* | 8 | 482 |

1.5 mm | 4.0 mm | 1.43* | 15 | 857 |

1.5 mm | 5.0 mm | 2.1* | 21 | 1257 |

1.5 mm | 6.0 mm | 2.7* | 27 | 1607 |

1.5 mm | 7.0 mm | 3.6* | 37 | 2187 |

1.5 mm | 8.0 mm | 3.9* | 39 | 2316 |

* Metric mL per revolution numbers are rounded off

To determine the chemical compatibility of a particular tubing material, it is recommended that you test the tubing under actual conditions

Tubing materials that can be used include Vinyl, Viton, Tygon, Silicone, Santoprene, and Norprene. Up to 68 durometer tubing can be used.

Table

Tubing Size | Due to | Between Pumps | Due to Different |

Inner Diameter | Motor | (due to Mechanical | Tubing Materials |

(in.) | Speed | Tolerances) |

|

|

|

|

|

1⁄32 | ±10% | ±25% | ±20% |

1⁄16 | ±10% | ±15% | ±15% |

1⁄8 | ±10% | ±10% | ±5% |

3⁄16 | ±5% | ±10% | ±5% |

1⁄4 | ±5% | ±15% | ±5% |

5⁄16 | ±15% | ±20% | ±10% |