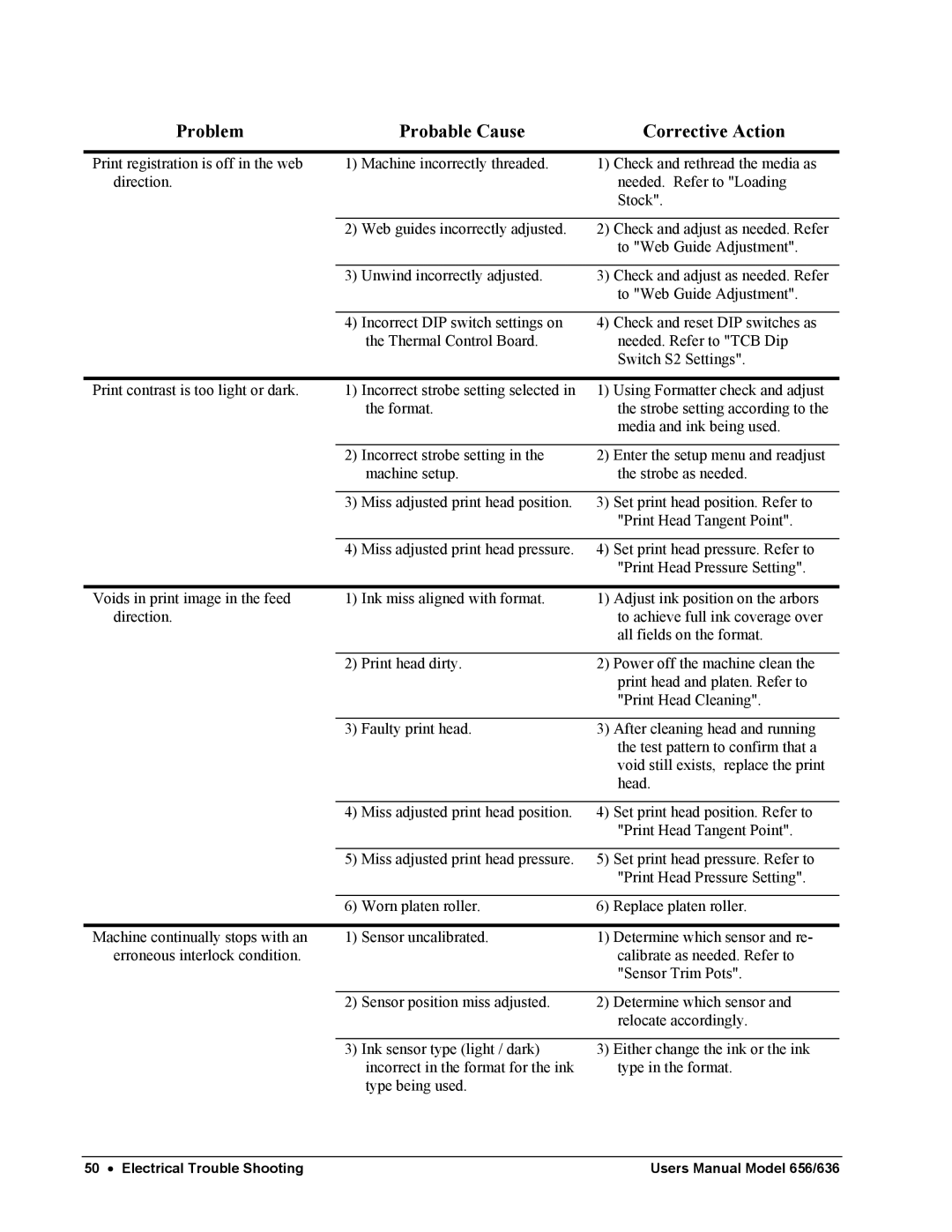

Problem |

| Probable Cause |

| Corrective Action |

|

|

|

| |

Print registration is off in the web | 1) Machine incorrectly threaded. | 1) | Check and rethread the media as | |

direction. |

|

|

| needed. Refer to "Loading |

|

|

|

| Stock". |

|

|

|

|

|

| 2) | Web guides incorrectly adjusted. | 2) | Check and adjust as needed. Refer |

|

|

|

| to "Web Guide Adjustment". |

|

|

|

|

|

| 3) | Unwind incorrectly adjusted. | 3) | Check and adjust as needed. Refer |

|

|

|

| to "Web Guide Adjustment". |

4)Incorrect DIP switch settings on the Thermal Control Board.

4)Check and reset DIP switches as needed. Refer to "TCB Dip Switch S2 Settings".

Print contrast is too light or dark.

1) | Incorrect strobe setting selected in | 1) | Using Formatter check and adjust |

| the format. |

| the strobe setting according to the |

|

|

| media and ink being used. |

|

|

|

|

2) | Incorrect strobe setting in the | 2) | Enter the setup menu and readjust |

| machine setup. |

| the strobe as needed. |

|

|

|

|

3) | Miss adjusted print head position. | 3) | Set print head position. Refer to |

|

|

| "Print Head Tangent Point". |

|

|

|

|

4) | Miss adjusted print head pressure. | 4) | Set print head pressure. Refer to |

|

|

| "Print Head Pressure Setting". |

Voids in print image in the feed direction.

1) Ink miss aligned with format.

1)Adjust ink position on the arbors to achieve full ink coverage over all fields on the format.

| 2) | Print head dirty. | 2) | Power off the machine clean the |

|

|

|

| print head and platen. Refer to |

|

|

|

| "Print Head Cleaning". |

|

|

|

|

|

| 3) | Faulty print head. | 3) | After cleaning head and running |

|

|

|

| the test pattern to confirm that a |

|

|

|

| void still exists, replace the print |

|

|

|

| head. |

|

|

|

|

|

| 4) | Miss adjusted print head position. | 4) | Set print head position. Refer to |

|

|

|

| "Print Head Tangent Point". |

|

|

|

|

|

| 5) | Miss adjusted print head pressure. | 5) | Set print head pressure. Refer to |

|

|

|

| "Print Head Pressure Setting". |

|

|

|

|

|

| 6) | Worn platen roller. | 6) | Replace platen roller. |

|

|

|

| |

Machine continually stops with an | 1) Sensor uncalibrated. | 1) | Determine which sensor and re- | |

erroneous interlock condition. |

|

|

| calibrate as needed. Refer to |

|

|

|

| "Sensor Trim Pots". |

2) Sensor position miss adjusted.

2)Determine which sensor and relocate accordingly.

3)Ink sensor type (light / dark) incorrect in the format for the ink type being used.

3)Either change the ink or the ink type in the format.

50 • Electrical Trouble Shooting | Users Manual Model 656/636 |