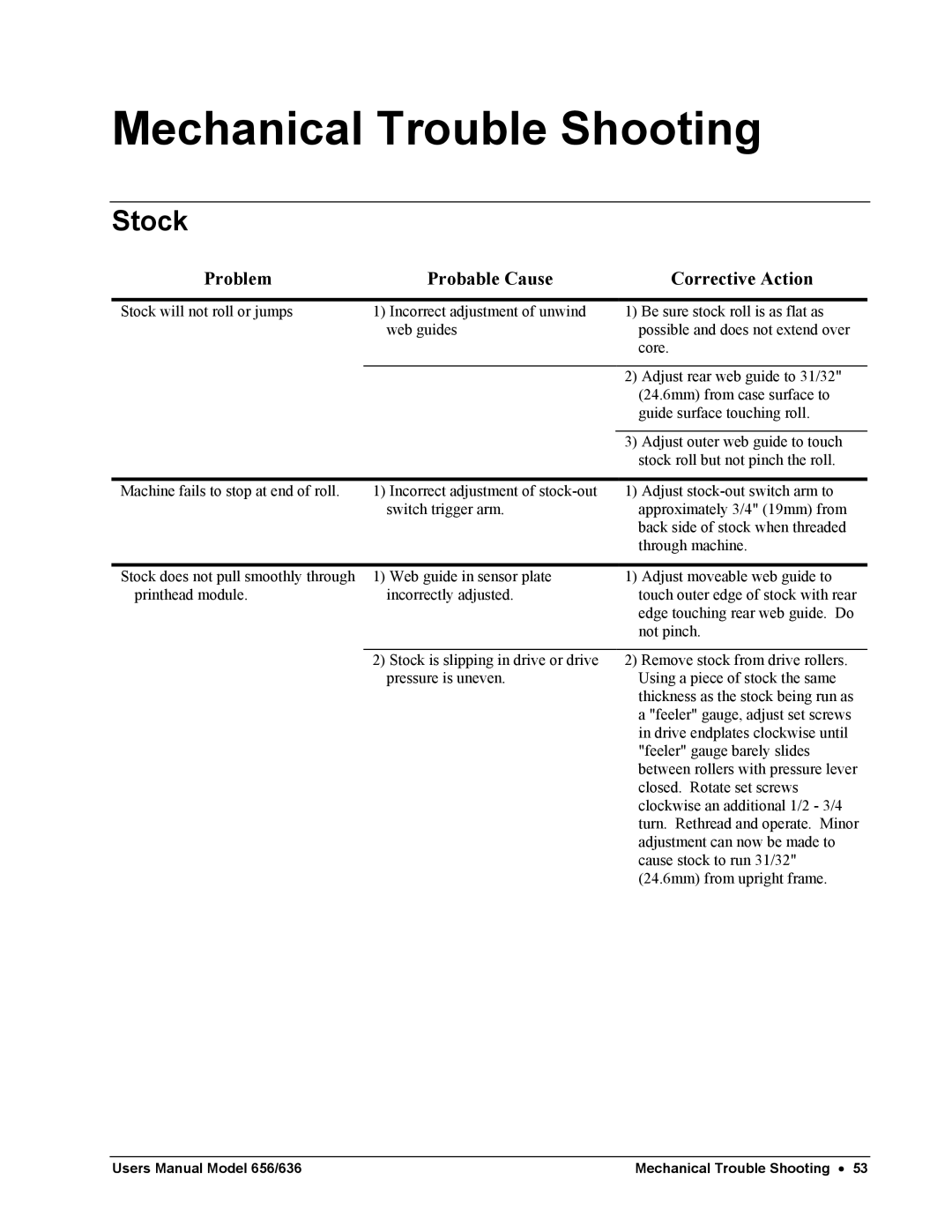

Mechanical Trouble Shooting

Stock

Problem | Probable Cause |

| Corrective Action |

|

|

|

|

Stock will not roll or jumps | 1) Incorrect adjustment of unwind | 1) | Be sure stock roll is as flat as |

| web guides |

| possible and does not extend over |

|

|

| core. |

|

|

|

|

|

| 2) | Adjust rear web guide to 31/32" |

|

|

| (24.6mm) from case surface to |

|

|

| guide surface touching roll. |

|

|

|

|

|

| 3) | Adjust outer web guide to touch |

|

|

| stock roll but not pinch the roll. |

|

|

|

|

Machine fails to stop at end of roll. | 1) Incorrect adjustment of | 1) | Adjust |

| switch trigger arm. |

| approximately 3/4" (19mm) from |

|

|

| back side of stock when threaded |

|

|

| through machine. |

Stock does not pull smoothly through printhead module.

1) Web guide in sensor plate | 1) Adjust moveable web guide to |

incorrectly adjusted. | touch outer edge of stock with rear |

| edge touching rear web guide. Do |

| not pinch. |

2)Stock is slipping in drive or drive pressure is uneven.

2)Remove stock from drive rollers. Using a piece of stock the same thickness as the stock being run as a "feeler" gauge, adjust set screws in drive endplates clockwise until "feeler" gauge barely slides between rollers with pressure lever closed. Rotate set screws clockwise an additional 1/2 - 3/4 turn. Rethread and operate. Minor adjustment can now be made to cause stock to run 31/32" (24.6mm) from upright frame.

Users Manual Model 656/636 | Mechanical Trouble Shooting • 53 |