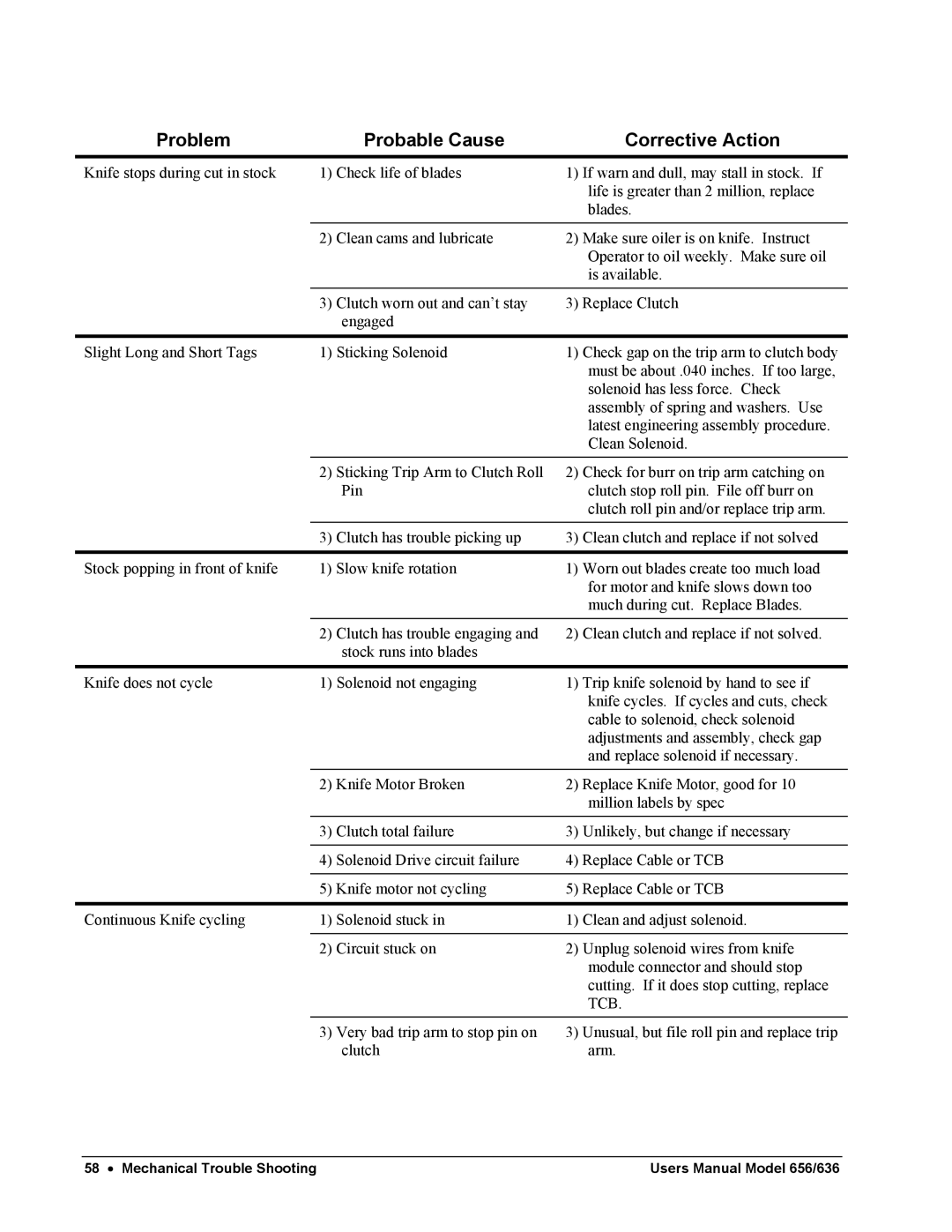

Problem |

| Probable Cause |

| Corrective Action |

Knife stops during cut in stock | 1) Check life of blades | 1) | If warn and dull, may stall in stock. If | |

|

|

|

| life is greater than 2 million, replace |

|

|

|

| blades. |

|

|

|

|

|

| 2) | Clean cams and lubricate | 2) | Make sure oiler is on knife. Instruct |

|

|

|

| Operator to oil weekly. Make sure oil |

|

|

|

| is available. |

|

|

|

|

|

| 3) | Clutch worn out and can’t stay | 3) | Replace Clutch |

|

| engaged |

|

|

|

|

|

| |

Slight Long and Short Tags | 1) Sticking Solenoid | 1) | Check gap on the trip arm to clutch body | |

|

|

|

| must be about .040 inches. If too large, |

|

|

|

| solenoid has less force. Check |

|

|

|

| assembly of spring and washers. Use |

|

|

|

| latest engineering assembly procedure. |

|

|

|

| Clean Solenoid. |

|

|

|

|

|

| 2) | Sticking Trip Arm to Clutch Roll | 2) | Check for burr on trip arm catching on |

|

| Pin |

| clutch stop roll pin. File off burr on |

|

|

|

| clutch roll pin and/or replace trip arm. |

|

|

|

|

|

| 3) | Clutch has trouble picking up | 3) | Clean clutch and replace if not solved |

|

|

| ||

Stock popping in front of knife | 1) Slow knife rotation | 1) Worn out blades create too much load | ||

|

|

|

| for motor and knife slows down too |

|

|

|

| much during cut. Replace Blades. |

|

|

|

|

|

| 2) | Clutch has trouble engaging and | 2) | Clean clutch and replace if not solved. |

|

| stock runs into blades |

|

|

|

|

|

| |

Knife does not cycle | 1) Solenoid not engaging | 1) | Trip knife solenoid by hand to see if | |

|

|

|

| knife cycles. If cycles and cuts, check |

|

|

|

| cable to solenoid, check solenoid |

|

|

|

| adjustments and assembly, check gap |

|

|

|

| and replace solenoid if necessary. |

|

|

|

|

|

| 2) | Knife Motor Broken | 2) | Replace Knife Motor, good for 10 |

|

|

|

| million labels by spec |

|

|

|

|

|

| 3) | Clutch total failure | 3) | Unlikely, but change if necessary |

|

|

|

|

|

| 4) | Solenoid Drive circuit failure | 4) | Replace Cable or TCB |

|

|

|

|

|

| 5) | Knife motor not cycling | 5) | Replace Cable or TCB |

|

|

|

| |

Continuous Knife cycling | 1) Solenoid stuck in | 1) | Clean and adjust solenoid. | |

|

|

|

|

|

| 2) | Circuit stuck on | 2) | Unplug solenoid wires from knife |

|

|

|

| module connector and should stop |

|

|

|

| cutting. If it does stop cutting, replace |

|

|

|

| TCB. |

3)Very bad trip arm to stop pin on clutch

3)Unusual, but file roll pin and replace trip arm.

58 • Mechanical Trouble Shooting | Users Manual Model 656/636 |