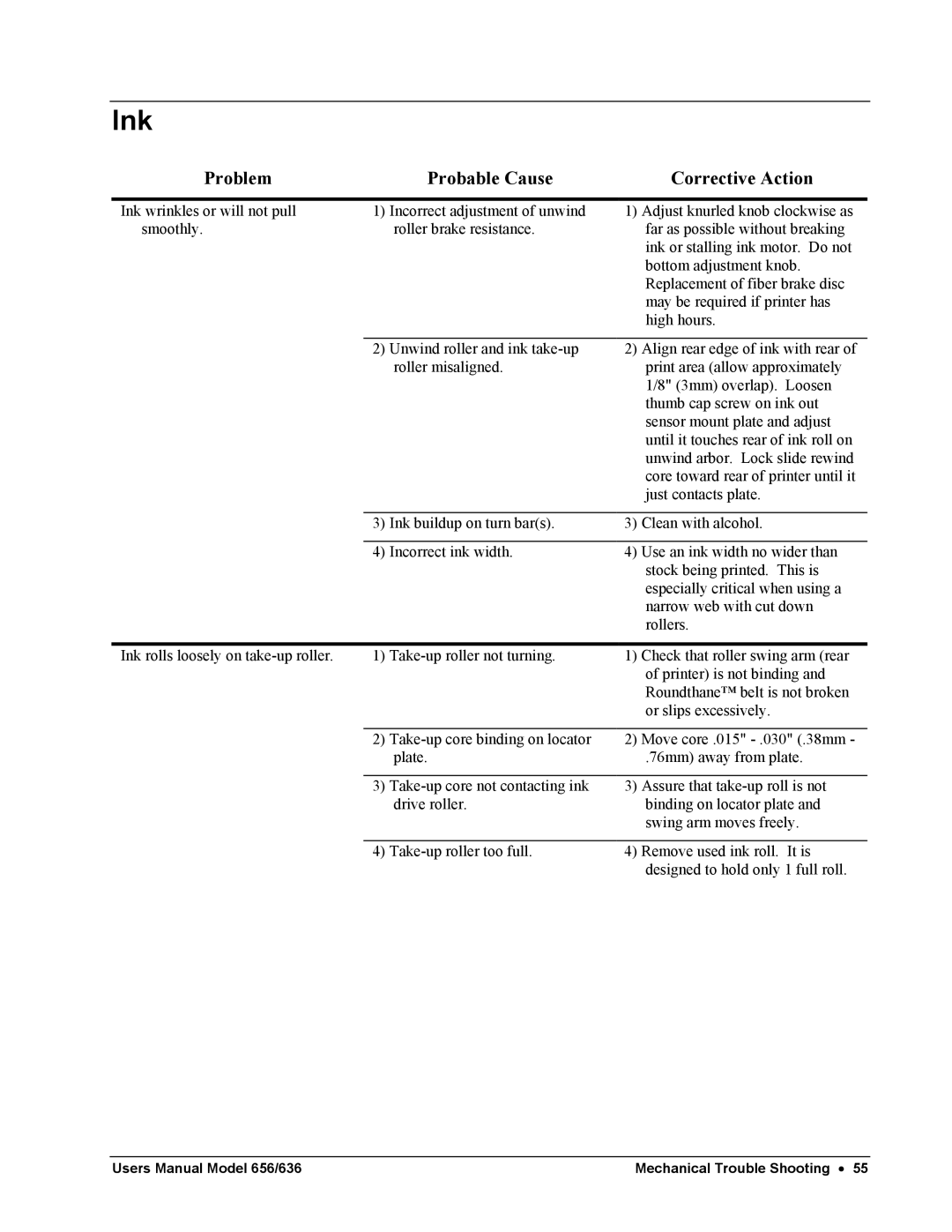

Ink

Problem | Probable Cause | Corrective Action |

Ink wrinkles or will not pull smoothly.

1)Incorrect adjustment of unwind roller brake resistance.

1)Adjust knurled knob clockwise as far as possible without breaking ink or stalling ink motor. Do not bottom adjustment knob.

Replacement of fiber brake disc may be required if printer has high hours.

2) Unwind roller and ink | 2) Align rear edge of ink with rear of |

roller misaligned. | print area (allow approximately |

| 1/8" (3mm) overlap). Loosen |

| thumb cap screw on ink out |

| sensor mount plate and adjust |

| until it touches rear of ink roll on |

| unwind arbor. Lock slide rewind |

| core toward rear of printer until it |

| just contacts plate. |

|

|

3) Ink buildup on turn bar(s). | 3) Clean with alcohol. |

|

|

4) Incorrect ink width. | 4) Use an ink width no wider than |

| stock being printed. This is |

| especially critical when using a |

| narrow web with cut down |

| rollers. |

Ink rolls loosely on

1) | 1) Check that roller swing arm (rear | ||

|

|

| of printer) is not binding and |

|

|

| Roundthane™ belt is not broken |

|

|

| or slips excessively. |

|

|

|

|

2) | 2) | Move core .015" | |

| plate. |

| .76mm) away from plate. |

|

|

|

|

3) | 3) | Assure that | |

| drive roller. |

| binding on locator plate and |

|

|

| swing arm moves freely. |

|

|

|

|

4) | 4) | Remove used ink roll. It is | |

|

|

| designed to hold only 1 full roll. |

Users Manual Model 656/636 | Mechanical Trouble Shooting • 55 |