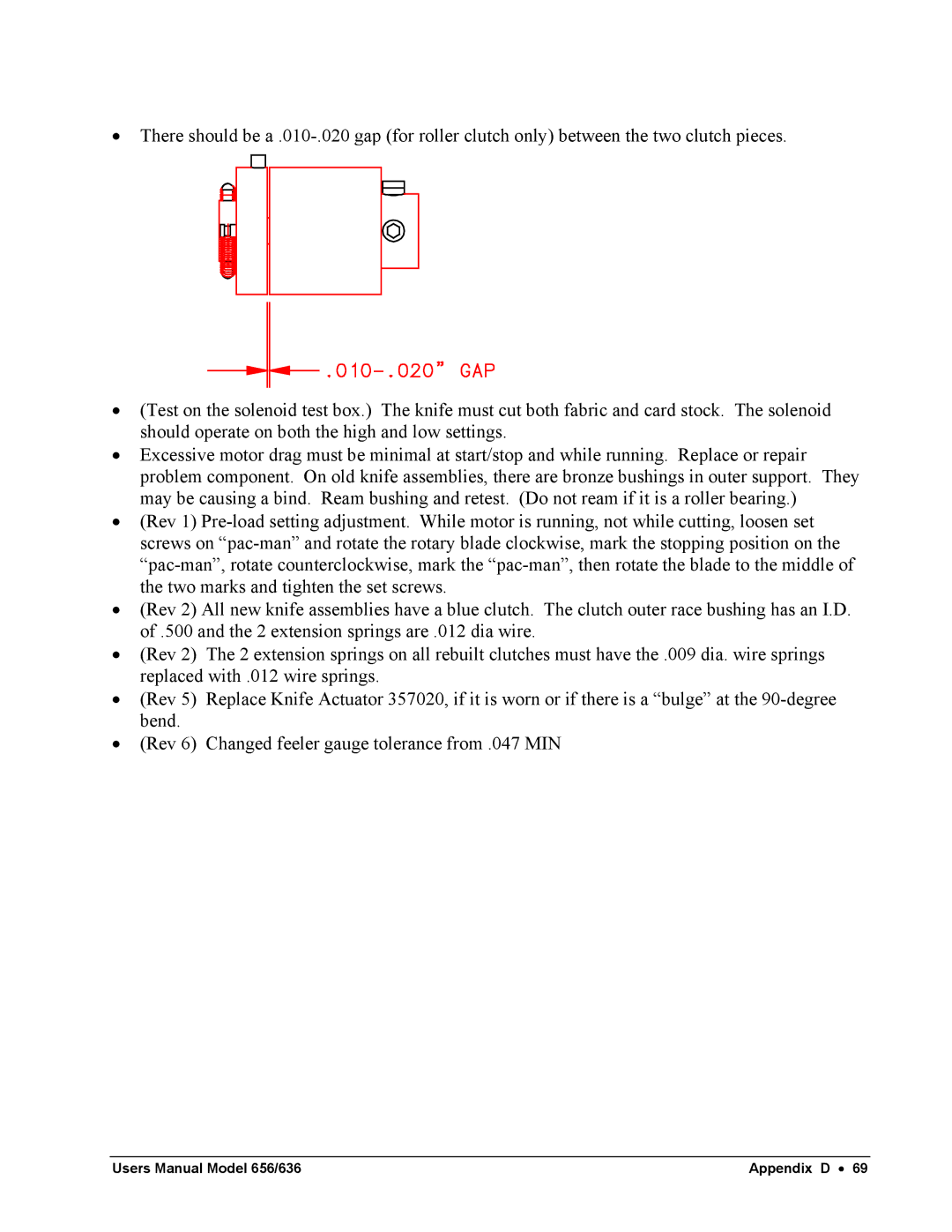

•There should be

•(Test on the solenoid test box.) The knife must cut both fabric and card stock. The solenoid should operate on both the high and low settings.

•Excessive motor drag must be minimal at start/stop and while running. Replace or repair problem component. On old knife assemblies, there are bronze bushings in outer support. They may be causing a bind. Ream bushing and retest. (Do not ream if it is a roller bearing.)

•(Rev 1)

•(Rev 2) All new knife assemblies have a blue clutch. The clutch outer race bushing has an I.D. of .500 and the 2 extension springs are .012 dia wire.

•(Rev 2) The 2 extension springs on all rebuilt clutches must have the .009 dia. wire springs replaced with .012 wire springs.

•(Rev 5) Replace Knife Actuator 357020, if it is worn or if there is a “bulge” at the

•(Rev 6) Changed feeler gauge tolerance from .047 MIN

Users Manual Model 656/636 | Appendix D • 69 |