Pressure Systems, Inc. | |

|

|

5.1.1Common Maintenance

The NetScanner™ System Intelligent Pressure Scanners are designed for rugged use. No special preventive maintenance is required, although periodic maintenance may be required to replace worn or damaged components. Upgrades or modifications of module hardware or firmware may also be periodically required. For users who wish to do their own maintenance and repair, maintenance kits and replacement parts may be purchased from the factory.

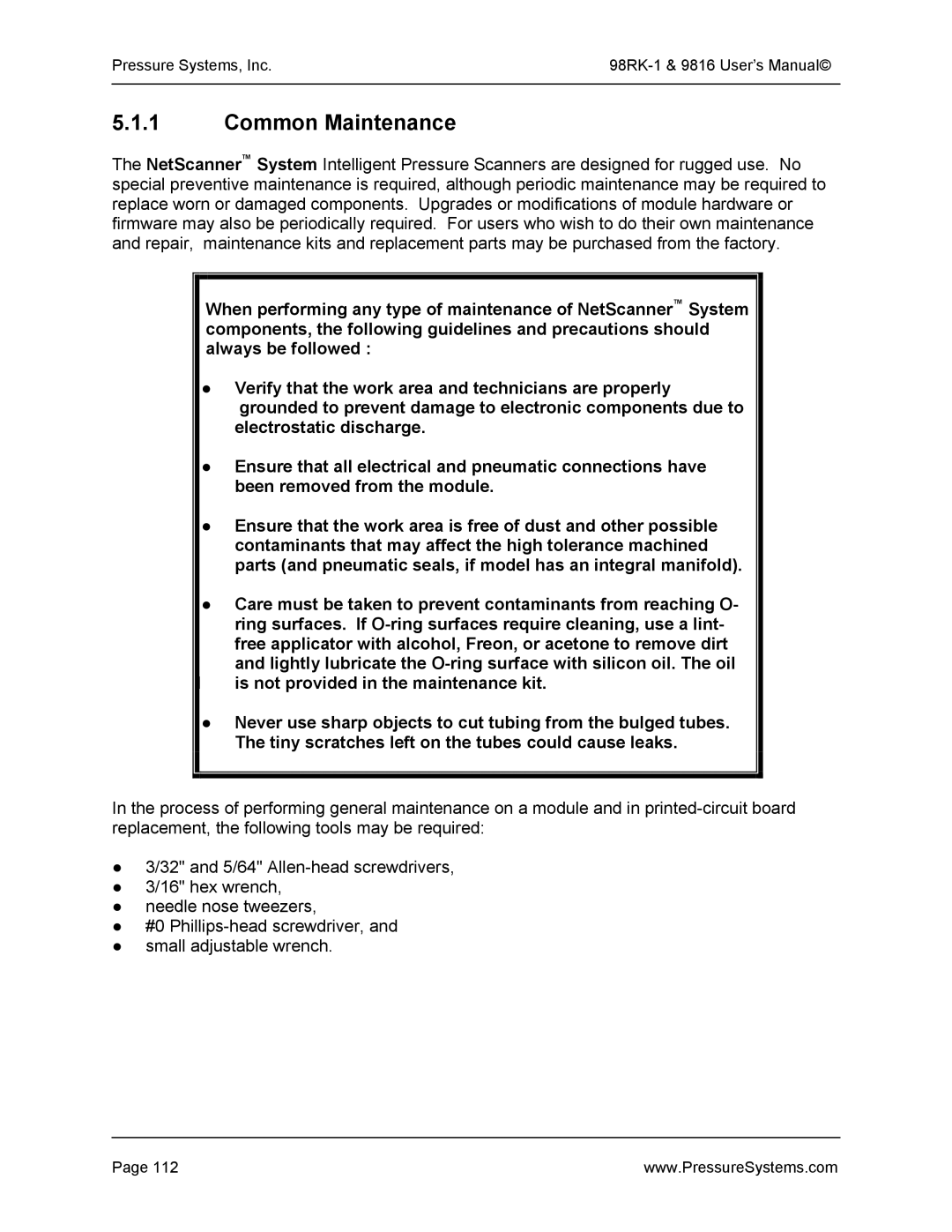

When performing any type of maintenance of NetScanner™ System components, the following guidelines and precautions should always be followed :

●Verify that the work area and technicians are properly grounded to prevent damage to electronic components due to electrostatic discharge.

●Ensure that all electrical and pneumatic connections have been removed from the module.

●Ensure that the work area is free of dust and other possible contaminants that may affect the high tolerance machined parts (and pneumatic seals, if model has an integral manifold).

●Care must be taken to prevent contaminants from reaching O- ring surfaces. If

lis not provided in the maintenance kit.

●Never use sharp objects to cut tubing from the bulged tubes. The tiny scratches left on the tubes could cause leaks.

In the process of performing general maintenance on a module and in

●3/32" and 5/64"

●3/16" hex wrench,

●needle nose tweezers,

●#0

●small adjustable wrench.

Page 112 | www.PressureSystems.com |