INSTALLATION

PILOT ADJUSTMENT

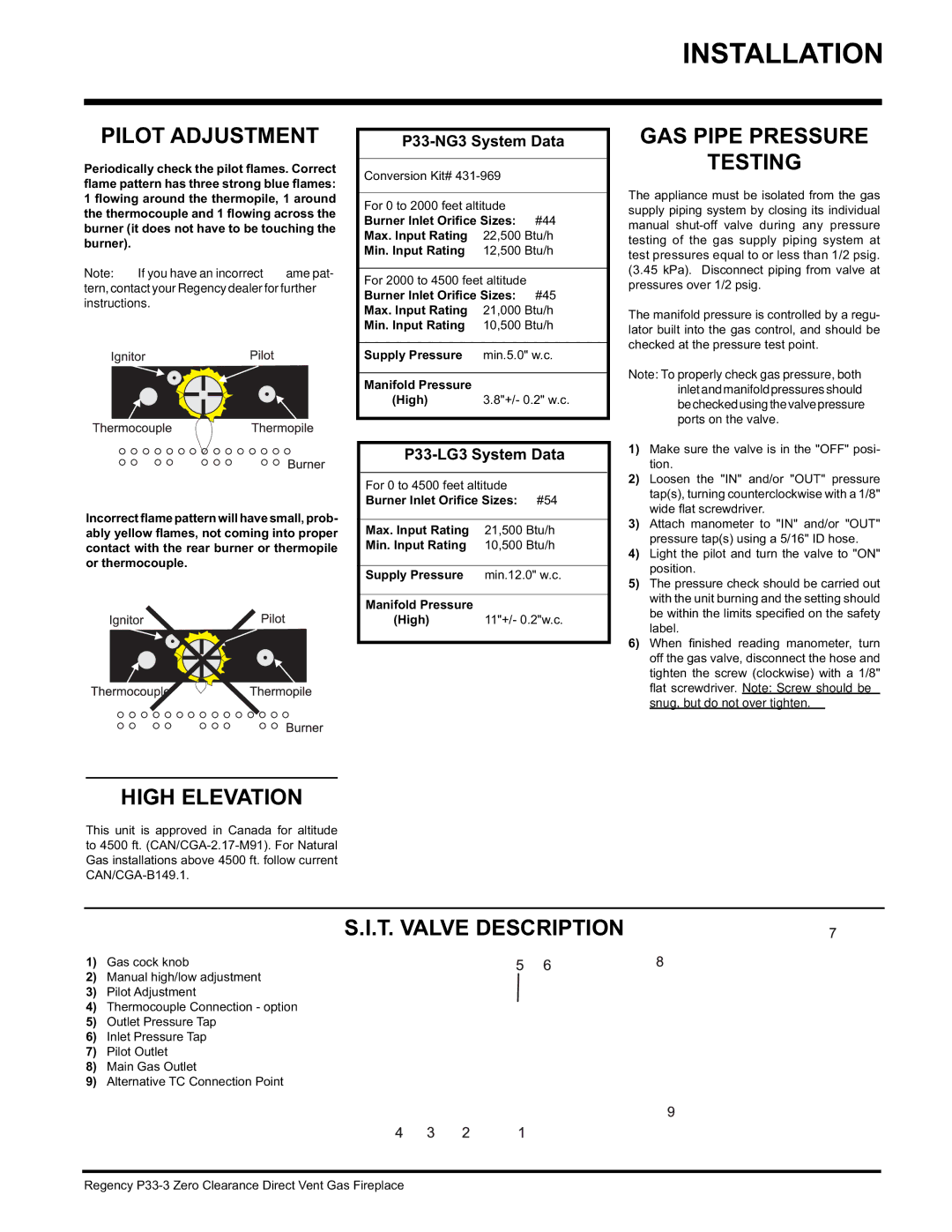

Periodically check the pilot flames. Correct flame pattern has three strong blue flames: 1 flowing around the thermopile, 1 around the thermocouple and 1 flowing across the burner (it does not have to be touching the burner).

Note: If you have an incorrect flame pat- tern, contact your Regency dealer for further instructions.

P33-NG3 System Data

Conversion Kit#

For 0 to 2000 feet altitude |

| |

Burner Inlet Orifice Sizes: | #44 | |

Max. Input Rating | 22,500 Btu/h | |

Min. Input Rating | 12,500 Btu/h | |

|

| |

For 2000 to 4500 feet altitude |

| |

Burner Inlet Orifice Sizes: | #45 | |

Max. Input Rating | 21,000 Btu/h | |

Min. Input Rating | 10,500 Btu/h | |

|

| |

Supply Pressure | min.5.0" w.c. | |

|

|

|

Manifold Pressure |

|

|

(High) | 3.8"+/- 0.2" w.c. | |

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas supply piping system by closing its individual manual

The manifold pressure is controlled by a regu- lator built into the gas control, and should be checked at the pressure test point.

Note: To properly check gas pressure, both inletandmanifoldpressuresshould becheckedusingthevalvepressure ports on the valve.

Incorrect flame pattern will have small, prob- ably yellow flames, not coming into proper contact with the rear burner or thermopile or thermocouple.

P33-LG3 System Data

For 0 to 4500 feet altitude

Burner Inlet Orifice Sizes: #54

Max. Input Rating | 21,500 Btu/h |

Min. Input Rating | 10,500 Btu/h |

|

|

Supply Pressure | min.12.0" w.c. |

|

|

Manifold Pressure |

|

(High) | 11"+/- 0.2"w.c. |

1)Make sure the valve is in the "OFF" posi- tion.

2)Loosen the "IN" and/or "OUT" pressure tap(s), turning counterclockwise with a 1/8" wide fl at screwdriver.

3)Attach manometer to "IN" and/or "OUT" pressure tap(s) using a 5/16" ID hose.

4)Light the pilot and turn the valve to "ON" position.

5)The pressure check should be carried out with the unit burning and the setting should be within the limits specifi ed on the safety label.

6)When fi nished reading manometer, turn off the gas valve, disconnect the hose and tighten the screw (clockwise) with a 1/8" fl at screwdriver. Note: Screw should be snug, but do not over tighten.

HIGH ELEVATION

This unit is approved in Canada for altitude to 4500 ft.

S.I.T. VALVE DESCRIPTION

1) Gas cock knob

2)Manual high/low adjustment

3)Pilot Adjustment

4) Thermocouple Connection - option

5) Outlet Pressure Tap

6) Inlet Pressure Tap

7)Pilot Outlet

8)Main Gas Outlet

9)Alternative TC Connection Point

Regency