CX208/212 Programming Guide

LABEL SENSING

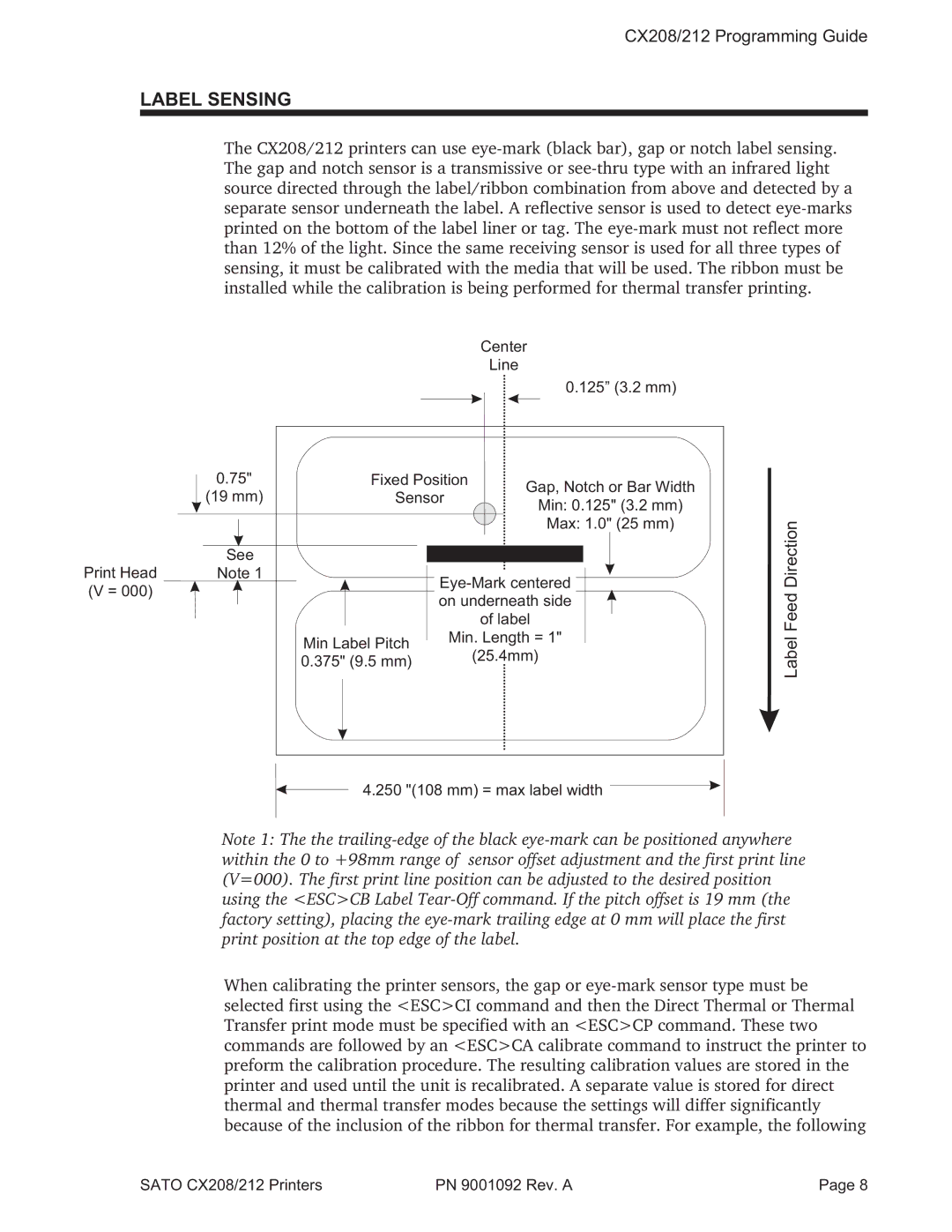

The CX208/212 printers can use eye-mark (black bar), gap or notch label sensing. The gap and notch sensor is a transmissive or see-thru type with an infrared light source directed through the label/ribbon combination from above and detected by a separate sensor underneath the label. A reflective sensor is used to detect eye-marks printed on the bottom of the label liner or tag. The eye-mark must not reflect more than 12% of the light. Since the same receiving sensor is used for all three types of sensing, it must be calibrated with the media that will be used. The ribbon must be installed while the calibration is being performed for thermal transfer printing.

| | | | Center |

| | | | Line |

| | | | 0.125” (3.2 mm) |

| 0.75" | Fixed Position | Gap, Notch or Bar Width |

| (19 mm) | Sensor |

| Min: 0.125" (3.2 mm) |

| | | |

| | | | Max: 1.0" (25 mm) |

| See | | | |

Print Head | Note 1 | | Eye-Mark centered |

(V = 000) | | |

| | on underneath side |

| | |

| | | | of label |

| | Min Label Pitch | Min. Length = 1" |

| | | (25.4mm) |

| | 0.375" (9.5 mm) | |

| | | |

4.250 "(108 mm) = max label width

Note 1: The the trailing-edge of the black eye-mark can be positioned anywhere within the 0 to +98mm range of sensor offset adjustment and the first print line (V=000). The first print line position can be adjusted to the desired position using the <ESC>CB Label Tear-Off command. If the pitch offset is 19 mm (the factory setting), placing the eye-mark trailing edge at 0 mm will place the first print position at the top edge of the label.

When calibrating the printer sensors, the gap or eye-mark sensor type must be selected first using the <ESC>CI command and then the Direct Thermal or Thermal Transfer print mode must be specified with an <ESC>CP command. These two commands are followed by an <ESC>CA calibrate command to instruct the printer to preform the calibration procedure. The resulting calibration values are stored in the printer and used until the unit is recalibrated. A separate value is stored for direct thermal and thermal transfer modes because the settings will differ significantly because of the inclusion of the ribbon for thermal transfer. For example, the following

SATO CX208/212 Printers | PN 9001092 Rev. A | Page 8 |