Dulcodes | Notes on safety of ProMinent¨ metering pumps |

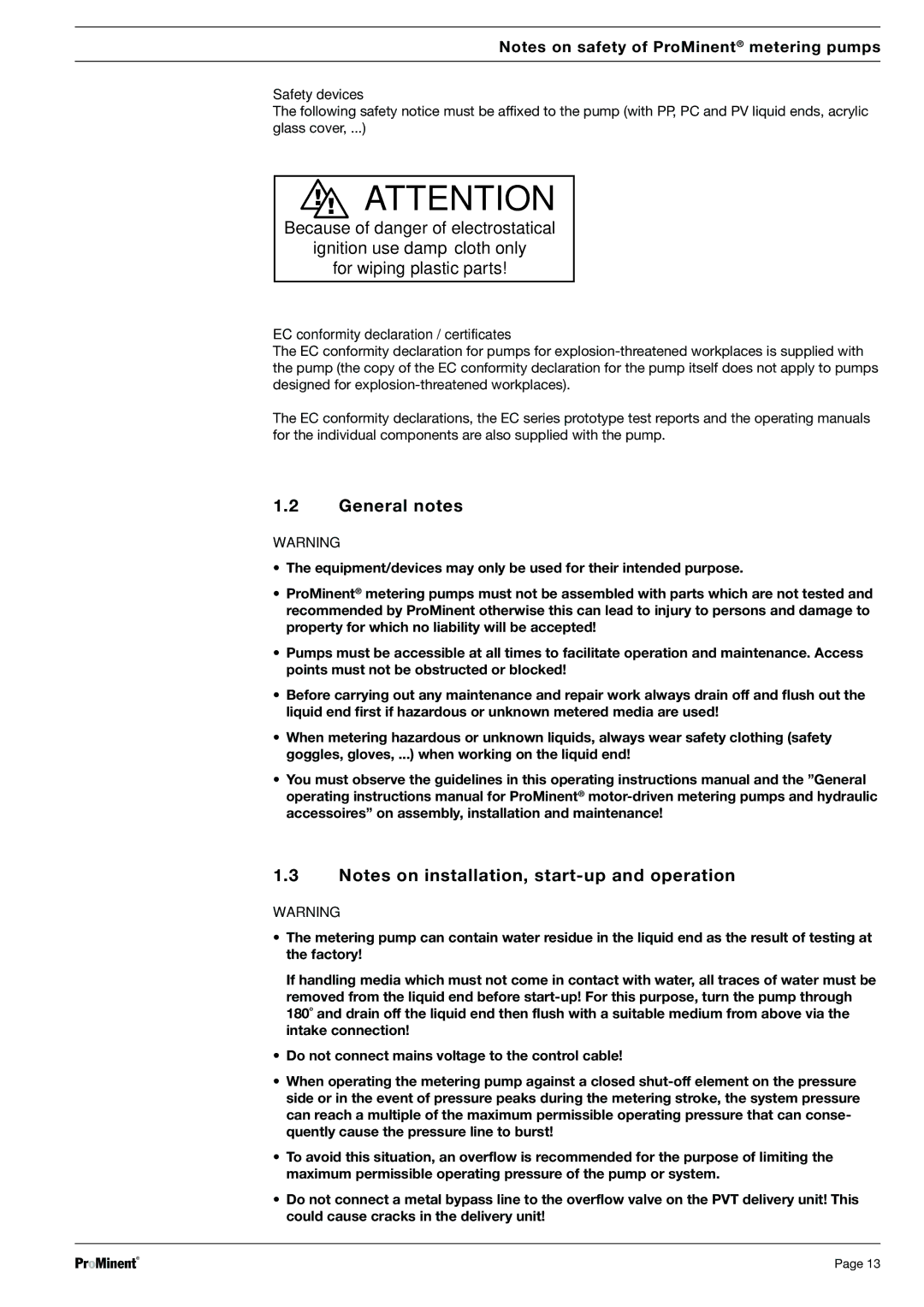

Safety devices

The following safety notice must be affixed to the pump (with PP, PC and PV liquid ends, acrylic glass cover, ...)

![]() ATTENTION

ATTENTION

Because of danger of electrostatical

ignition use damp cloth only

for wiping plastic parts!

EC conformity declaration / certificates

The EC conformity declaration for pumps for

The EC conformity declarations, the EC series prototype test reports and the operating manuals for the individual components are also supplied with the pump.

1.2General notes

WARNING

¥The equipment/devices may only be used for their intended purpose.

¥ProMinent¨ metering pumps must not be assembled with parts which are not tested and recommended by ProMinent otherwise this can lead to injury to persons and damage to property for which no liability will be accepted!

¥Pumps must be accessible at all times to facilitate operation and maintenance. Access points must not be obstructed or blocked!

¥Before carrying out any maintenance and repair work always drain off and flush out the liquid end first if hazardous or unknown metered media are used!

¥When metering hazardous or unknown liquids, always wear safety clothing (safety goggles, gloves, ...) when working on the liquid end!

¥You must observe the guidelines in this operating instructions manual and the ÓGeneral operating instructions manual for ProMinent¨

1.3Notes on installation,

WARNING

¥The metering pump can contain water residue in the liquid end as the result of testing at the factory!

If handling media which must not come in contact with water, all traces of water must be removed from the liquid end before

¥Do not connect mains voltage to the control cable!

¥When operating the metering pump against a closed

¥To avoid this situation, an overflow is recommended for the purpose of limiting the maximum permissible operating pressure of the pump or system.

¥Do not connect a metal bypass line to the overflow valve on the PVT delivery unit! This could cause cracks in the delivery unit!

ProMinent® | Page 13 |