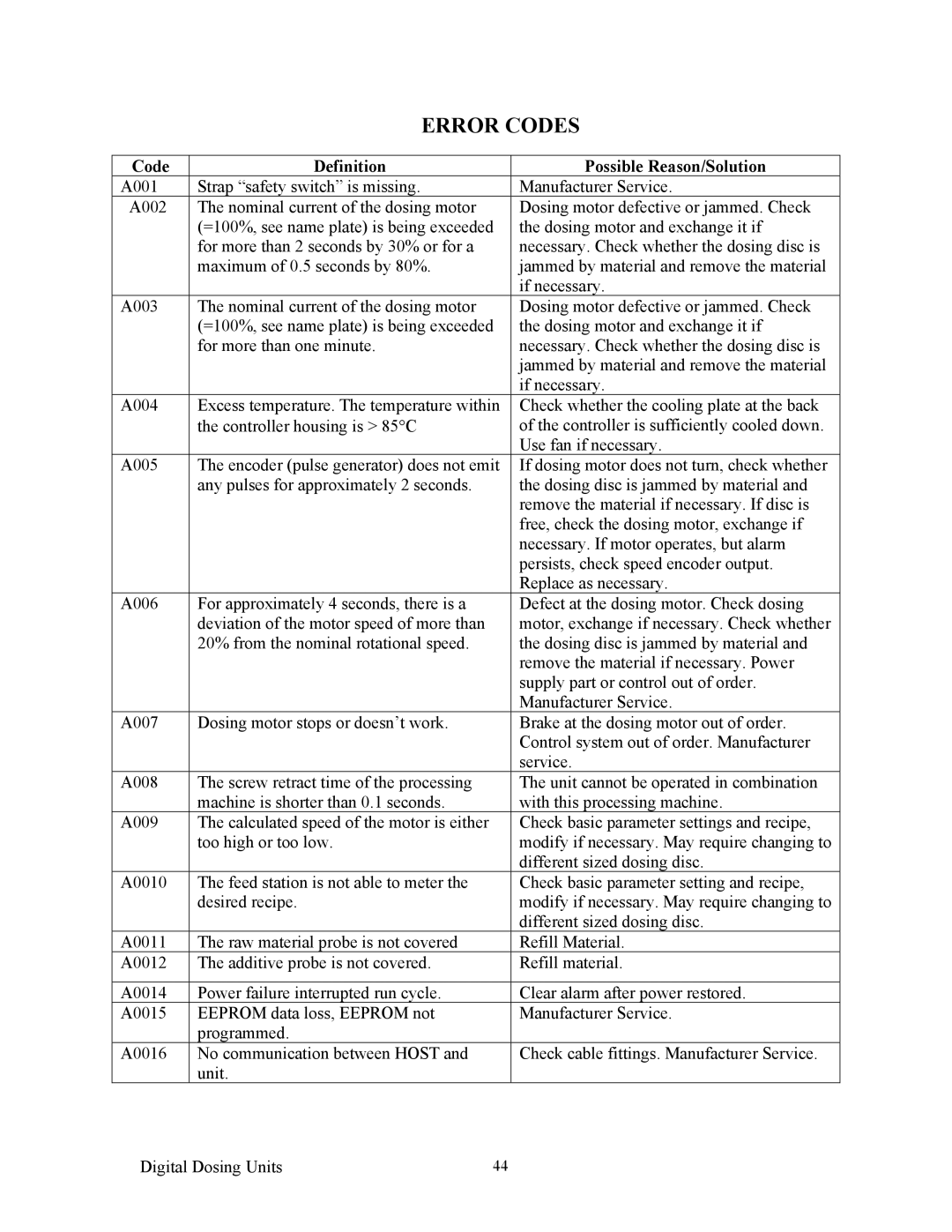

ERROR CODES

Code | Definition | Possible Reason/Solution |

A001 | Strap “safety switch” is missing. | Manufacturer Service. |

A002 | The nominal current of the dosing motor | Dosing motor defective or jammed. Check |

| (=100%, see name plate) is being exceeded | the dosing motor and exchange it if |

| for more than 2 seconds by 30% or for a | necessary. Check whether the dosing disc is |

| maximum of 0.5 seconds by 80%. | jammed by material and remove the material |

|

| if necessary. |

A003 | The nominal current of the dosing motor | Dosing motor defective or jammed. Check |

| (=100%, see name plate) is being exceeded | the dosing motor and exchange it if |

| for more than one minute. | necessary. Check whether the dosing disc is |

|

| jammed by material and remove the material |

|

| if necessary. |

A004 | Excess temperature. The temperature within | Check whether the cooling plate at the back |

| the controller housing is > 85°C | of the controller is sufficiently cooled down. |

|

| Use fan if necessary. |

A005 | The encoder (pulse generator) does not emit | If dosing motor does not turn, check whether |

| any pulses for approximately 2 seconds. | the dosing disc is jammed by material and |

|

| remove the material if necessary. If disc is |

|

| free, check the dosing motor, exchange if |

|

| necessary. If motor operates, but alarm |

|

| persists, check speed encoder output. |

|

| Replace as necessary. |

A006 | For approximately 4 seconds, there is a | Defect at the dosing motor. Check dosing |

| deviation of the motor speed of more than | motor, exchange if necessary. Check whether |

| 20% from the nominal rotational speed. | the dosing disc is jammed by material and |

|

| remove the material if necessary. Power |

|

| supply part or control out of order. |

|

| Manufacturer Service. |

A007 | Dosing motor stops or doesn’t work. | Brake at the dosing motor out of order. |

|

| Control system out of order. Manufacturer |

|

| service. |

A008 | The screw retract time of the processing | The unit cannot be operated in combination |

| machine is shorter than 0.1 seconds. | with this processing machine. |

A009 | The calculated speed of the motor is either | Check basic parameter settings and recipe, |

| too high or too low. | modify if necessary. May require changing to |

|

| different sized dosing disc. |

A0010 | The feed station is not able to meter the | Check basic parameter setting and recipe, |

| desired recipe. | modify if necessary. May require changing to |

|

| different sized dosing disc. |

A0011 | The raw material probe is not covered | Refill Material. |

A0012 | The additive probe is not covered. | Refill material. |

|

|

|

A0014 | Power failure interrupted run cycle. | Clear alarm after power restored. |

A0015 | EEPROM data loss, EEPROM not | Manufacturer Service. |

| programmed. |

|

A0016 | No communication between HOST and | Check cable fittings. Manufacturer Service. |

| unit. |

|

Digital Dosing Units | 44 |