5 Maintenance & Troubleshooting

Analyzers equipped with a scrubber should only be used with inert gases and saturat- ed hydrocarbons.

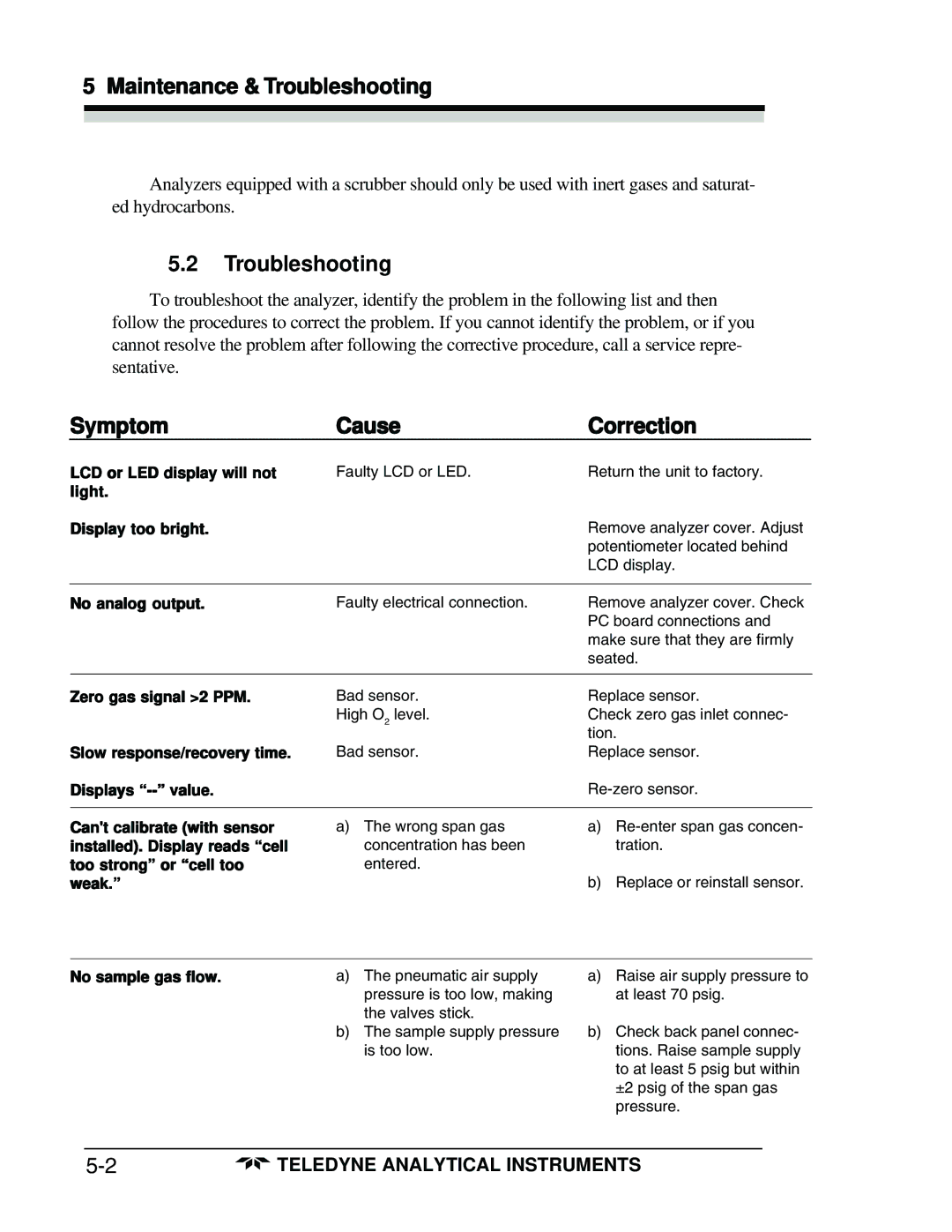

5.2Troubleshooting

To troubleshoot the analyzer, identify the problem in the following list and then

follow the procedures to correct the problem. If you cannot identify the problem, or if you cannot resolve the problem after following the corrective procedure, call a service repre- sentative.

Symptom | Cause | Correction |

LCD or LED display will not | Faulty LCD or LED. | Return the unit to factory. |

light. |

|

|

Display too bright. |

| Remove analyzer cover. Adjust |

|

| potentiometer located behind |

|

| LCD display. |

|

|

|

No analog output. | Faulty electrical connection. | Remove analyzer cover. Check |

|

| PC board connections and |

|

| make sure that they are firmly |

|

| seated. |

|

|

|

Zero gas signal >2 PPM. | Bad sensor. | Replace sensor. |

| High O2 level. | Check zero gas inlet connec- |

|

| tion. |

Slow response/recovery time. | Bad sensor. | Replace sensor. |

Displays |

| |

|

|

|

Can't calibrate (with sensor installed). Display reads “cell too strong” or “cell too weak.”

a)The wrong span gas concentration has been entered.

a)

b)Replace or reinstall sensor.

No sample gas flow. | a) | The pneumatic air supply |

|

| pressure is too low, making |

|

| the valves stick. |

| b) | The sample supply pressure |

|

| is too low. |

a)Raise air supply pressure to at least 70 psig.

b)Check back panel connec- tions. Raise sample supply to at least 5 psig but within ±2 psig of the span gas pressure.

TELEDYNE ANALYTICAL INSTRUMENTS |