Infrared Gas Analyzer | Installation 2 | |

|

|

|

|

|

|

|

|

|

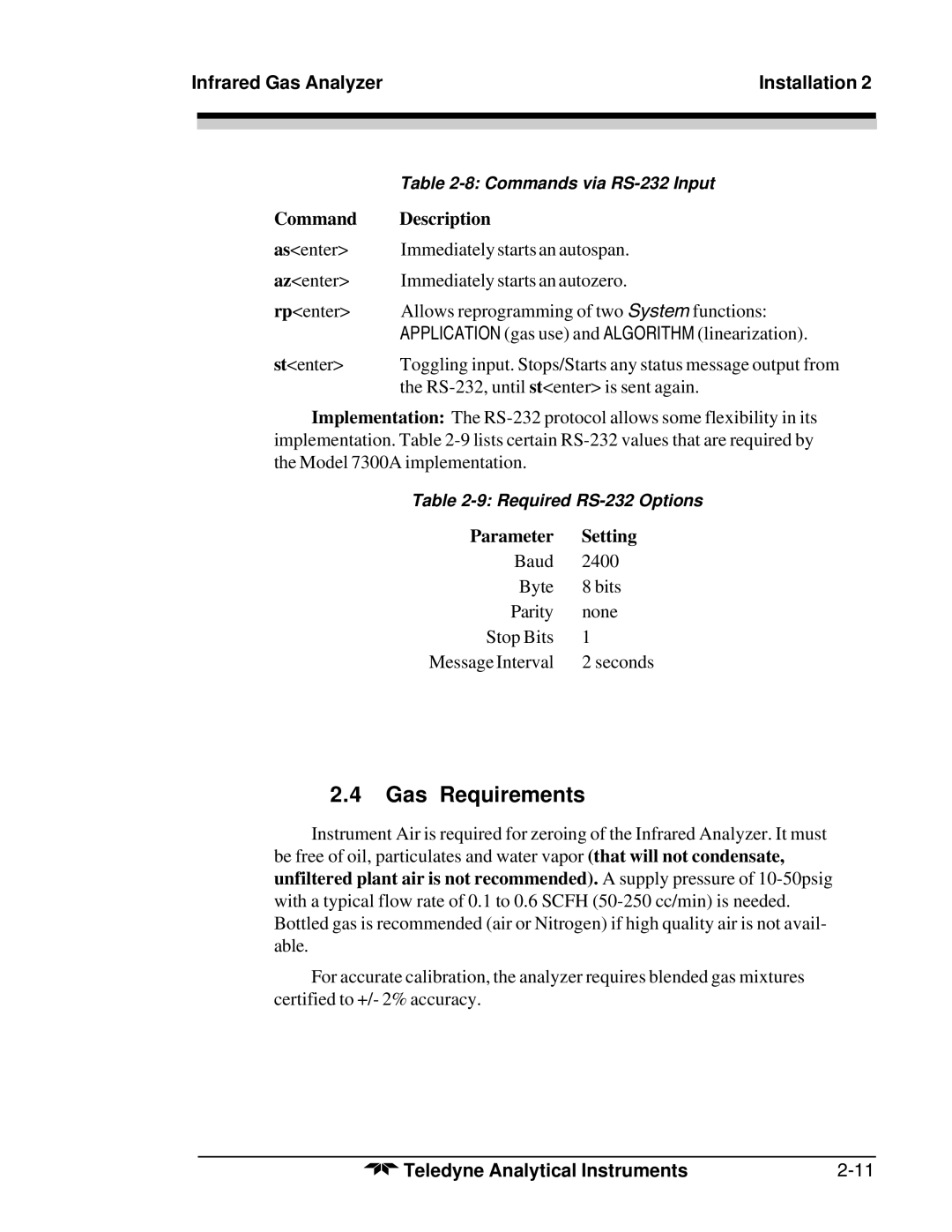

| Table |

Command | Description |

as<enter> | Immediately starts an autospan. |

az<enter> | Immediately starts an autozero. |

rp<enter> | Allows reprogramming of two System functions: |

| APPLICATION (gas use) and ALGORITHM (linearization). |

st<enter> | Toggling input. Stops/Starts any status message output from |

| the |

Implementation: The

Table

Parameter | Setting |

Baud | 2400 |

Byte | 8 bits |

Parity | none |

Stop Bits | 1 |

Message Interval | 2 seconds |

2.4Gas Requirements

Instrument Air is required for zeroing of the Infrared Analyzer. It must be free of oil, particulates and water vapor (that will not condensate, unfiltered plant air is not recommended). A supply pressure of

For accurate calibration, the analyzer requires blended gas mixtures certified to +/- 2% accuracy.

Teledyne Analytical Instruments |