5 Maintenance | Model 7300A | |

|

|

|

|

|

|

|

|

|

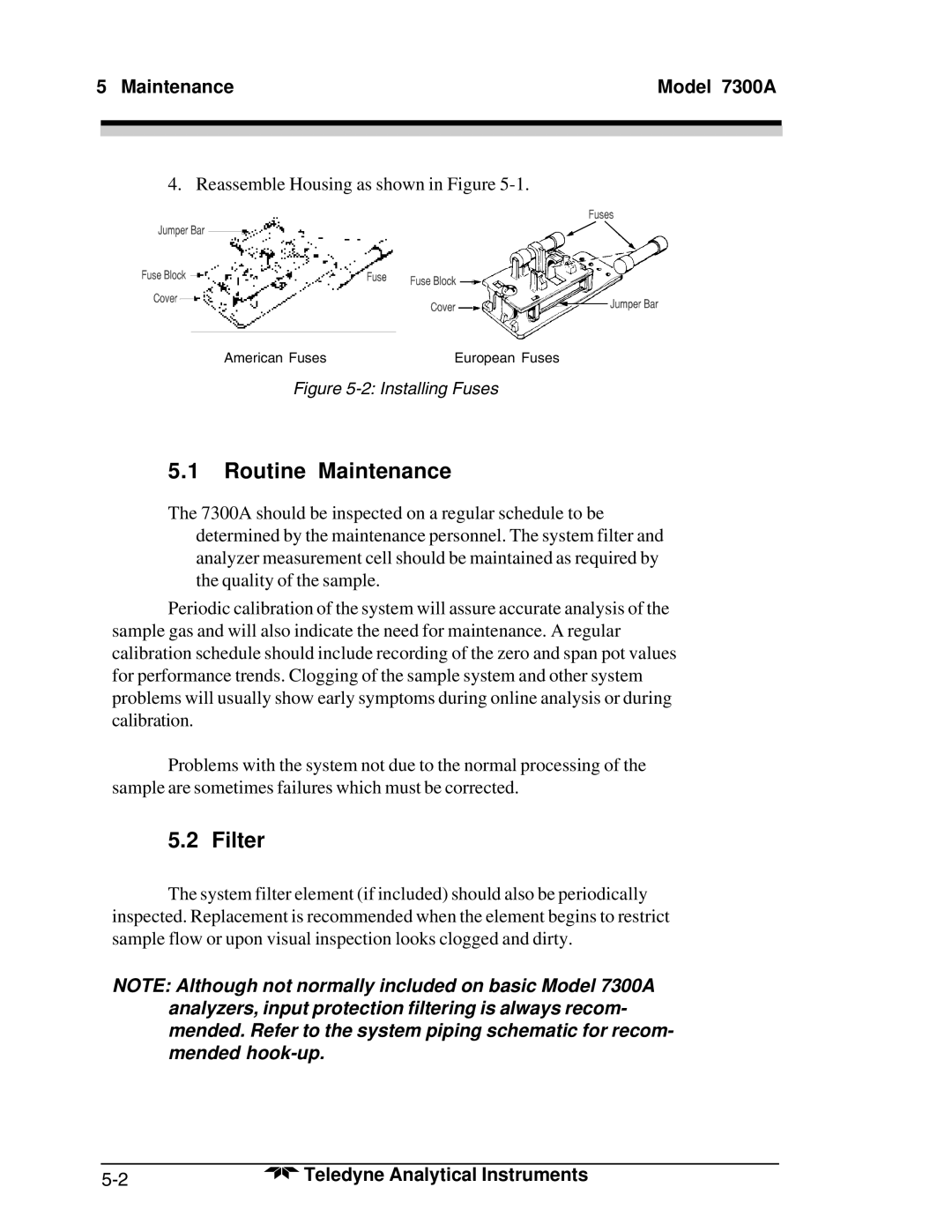

4. Reassemble Housing as shown in Figure

American Fuses | European Fuses |

Figure 5-2: Installing Fuses

5.1Routine Maintenance

The 7300A should be inspected on a regular schedule to be determined by the maintenance personnel. The system filter and analyzer measurement cell should be maintained as required by the quality of the sample.

Periodic calibration of the system will assure accurate analysis of the sample gas and will also indicate the need for maintenance. A regular calibration schedule should include recording of the zero and span pot values for performance trends. Clogging of the sample system and other system problems will usually show early symptoms during online analysis or during calibration.

Problems with the system not due to the normal processing of the sample are sometimes failures which must be corrected.

5.2 Filter

The system filter element (if included) should also be periodically inspected. Replacement is recommended when the element begins to restrict sample flow or upon visual inspection looks clogged and dirty.

NOTE: Although not normally included on basic Model 7300A analyzers, input protection filtering is always recom- mended. Refer to the system piping schematic for recom- mended

Teledyne Analytical Instruments |