MAINTENANCE

With the cutter head lowered, locate the grease zerks on the linkage and pivot bosses. Inject Lithium- Complex Extreme Pressure grease conforming to

GREASING THE REAR DRIVE BEARING AND EXTENSION COUPLER SHAFT

Locate the grease zerks for the rear flail drive extension shaft. Make sure the zerks are clean before injecting grease. One pump of grease into flange zerk and shaft coupler once every day or for every 8 hours of service.

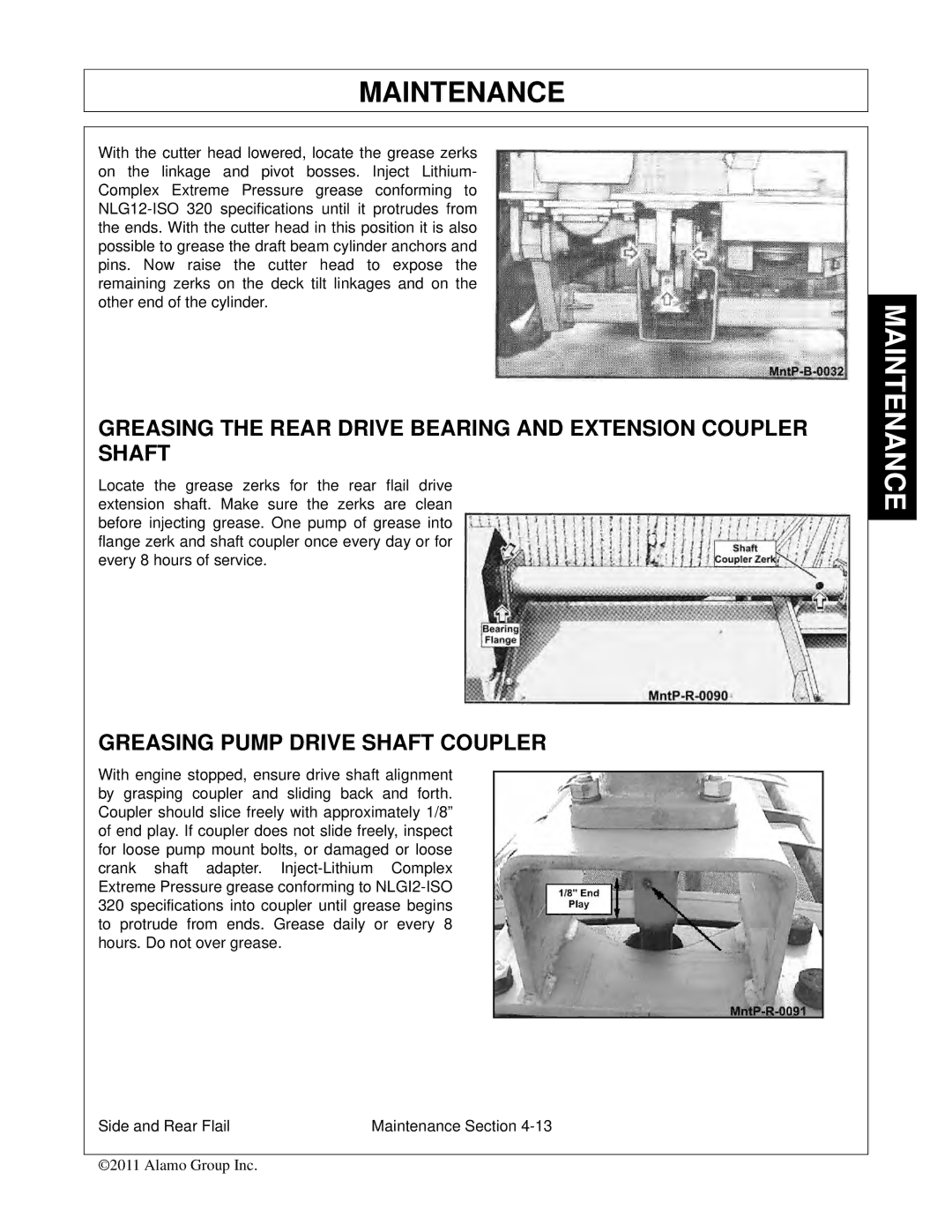

GREASING PUMP DRIVE SHAFT COUPLER

With engine stopped, ensure drive shaft alignment by grasping coupler and sliding back and forth. Coupler should slice freely with approximately 1/8” of end play. If coupler does not slide freely, inspect for loose pump mount bolts, or damaged or loose crank shaft adapter.

Side and Rear Flail | Maintenance Section |

©2011 Alamo Group Inc.