MAINTENANCE

MAINTENANCE

GREASING CUTTER SHAFT-FLAIL MOWERS

Locate grease zerks on each end of cutter shaft(s). These are located on the bearing cover. Normal conditions require one or two pumps in each bearing, using

Over greasing may cause premature seal failure.

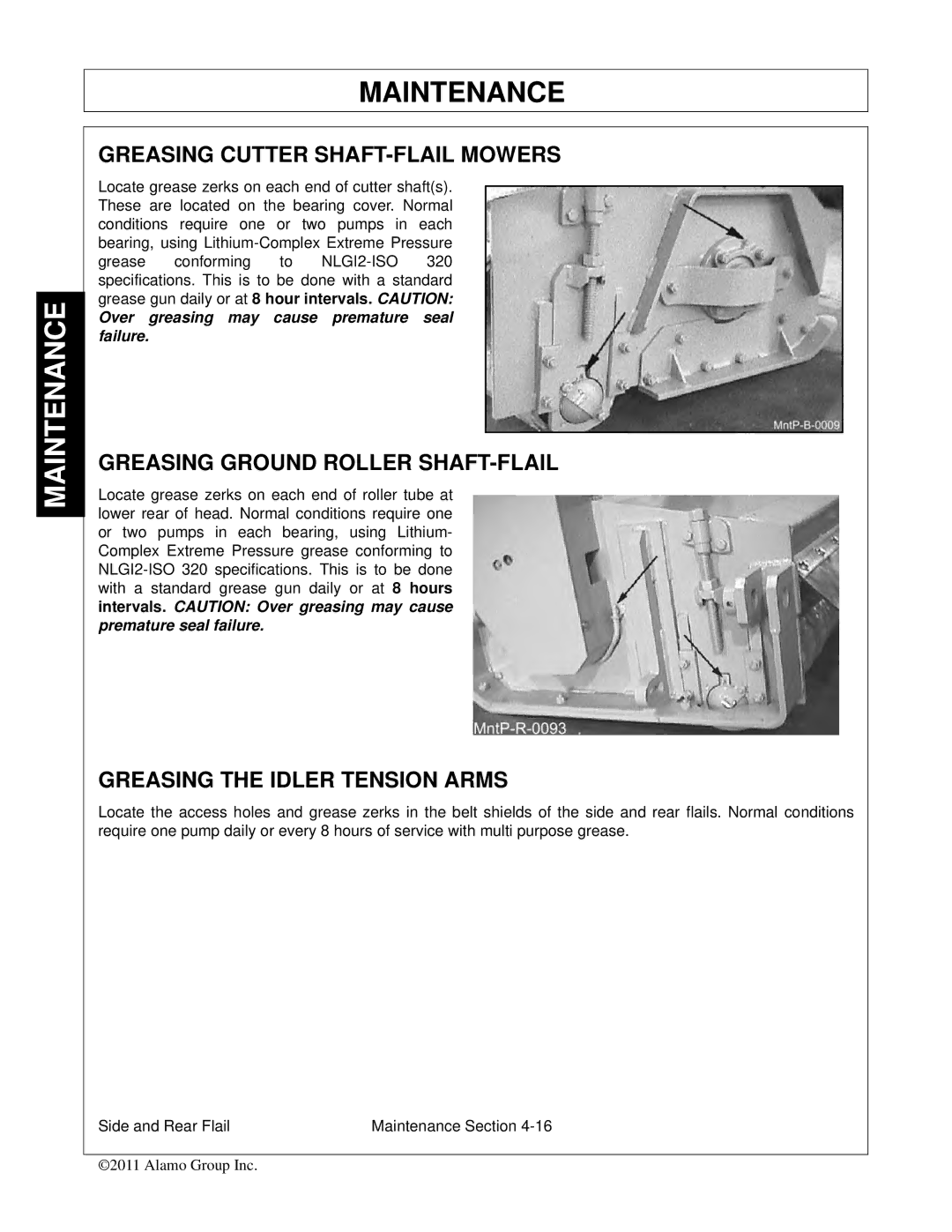

GREASING GROUND ROLLER SHAFT-FLAIL

Locate grease zerks on each end of roller tube at lower rear of head. Normal conditions require one or two pumps in each bearing, using Lithium- Complex Extreme Pressure grease conforming to

GREASING THE IDLER TENSION ARMS

Locate the access holes and grease zerks in the belt shields of the side and rear flails. Normal conditions require one pump daily or every 8 hours of service with multi purpose grease.

Side and Rear Flail | Maintenance Section |

©2011 Alamo Group Inc.