MAINTENANCE

5c. Remove large nut on side of large

|

|

|

| valve block. Remove spring, and use |

|

|

|

| needle nose vise grip to pull spool |

|

|

|

| from block. Check block and spool |

|

|

|

| for contaminates and scratches. |

|

|

|

| Clean parts or replace if scratched. |

|

|

|

|

|

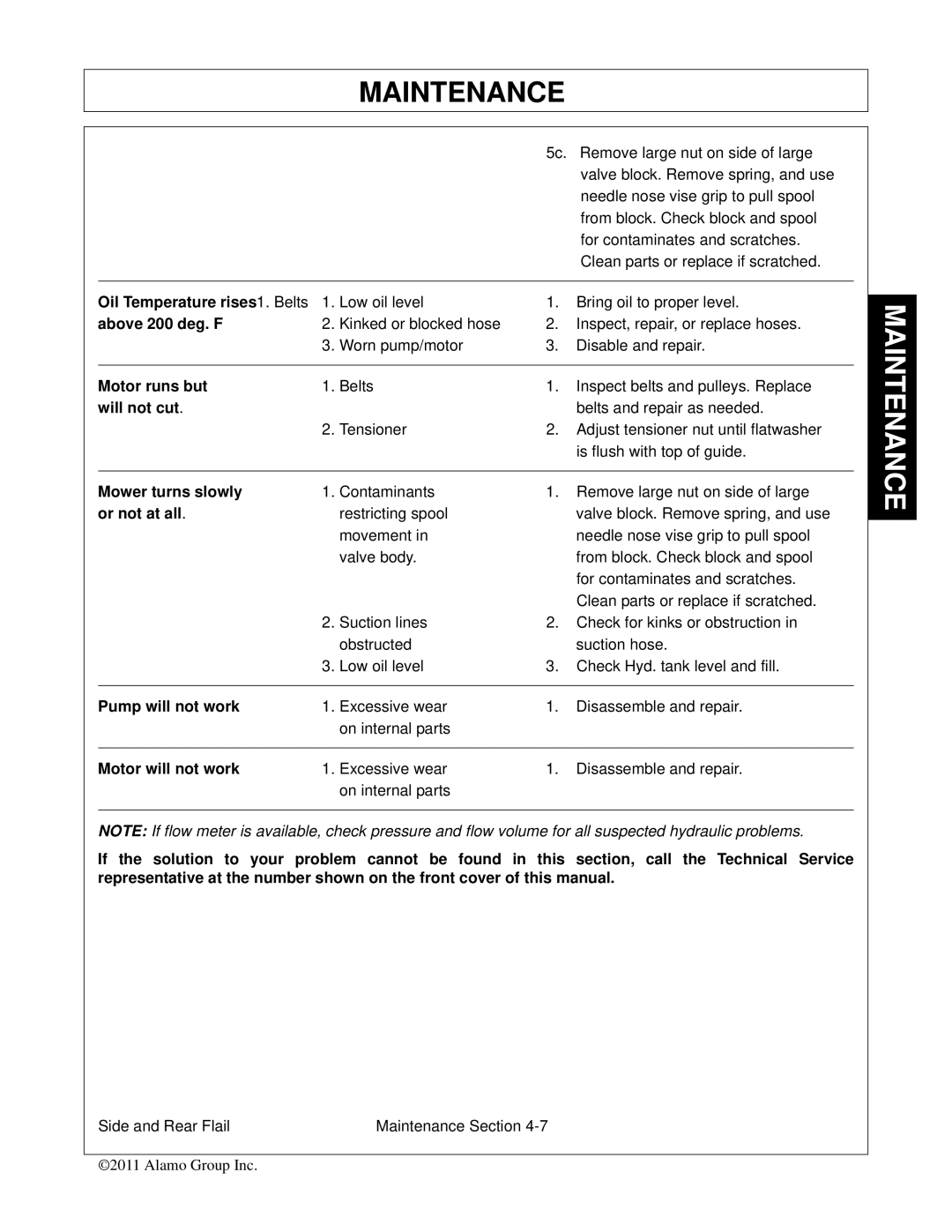

Oil Temperature rises1. Belts | 1. | Low oil level | 1. | Bring oil to proper level. |

above 200 deg. F | 2. | Kinked or blocked hose | 2. | Inspect, repair, or replace hoses. |

| 3. | Worn pump/motor | 3. | Disable and repair. |

|

|

|

|

|

Motor runs but | 1. | Belts | 1. | Inspect belts and pulleys. Replace |

will not cut. |

|

|

| belts and repair as needed. |

| 2. | Tensioner | 2. | Adjust tensioner nut until flatwasher |

|

|

|

| is flush with top of guide. |

|

|

|

|

|

Mower turns slowly | 1. | Contaminants | 1. | Remove large nut on side of large |

or not at all. |

| restricting spool |

| valve block. Remove spring, and use |

|

| movement in |

| needle nose vise grip to pull spool |

|

| valve body. |

| from block. Check block and spool |

|

|

|

| for contaminates and scratches. |

|

|

|

| Clean parts or replace if scratched. |

| 2. | Suction lines | 2. | Check for kinks or obstruction in |

|

| obstructed |

| suction hose. |

| 3. | Low oil level | 3. | Check Hyd. tank level and fill. |

|

|

|

|

|

Pump will not work | 1. | Excessive wear | 1. | Disassemble and repair. |

|

| on internal parts |

|

|

|

|

|

|

|

Motor will not work | 1. | Excessive wear | 1. | Disassemble and repair. |

|

| on internal parts |

|

|

NOTE: If flow meter is available, check pressure and flow volume for all suspected hydraulic problems.

If the solution to your problem cannot be found in this section, call the Technical Service representative at the number shown on the front cover of this manual.

Side and Rear Flail | Maintenance Section |

©2011 Alamo Group Inc.