MAINTENANCE

MAINTENANCE

GREASING THE UPPER AND LOWER SHEAVES

Locate the grease zerks on the ends of the upper and lower sheave pins.

GREASING P.T.O. SHAFTS

After bringing the tractor to a complete stop, shut off the engine and remove he PTO shaft from the tractor. Slide the shaft apart to expose the grease zerk. Grease the shaft with 5 pumps of grease and the

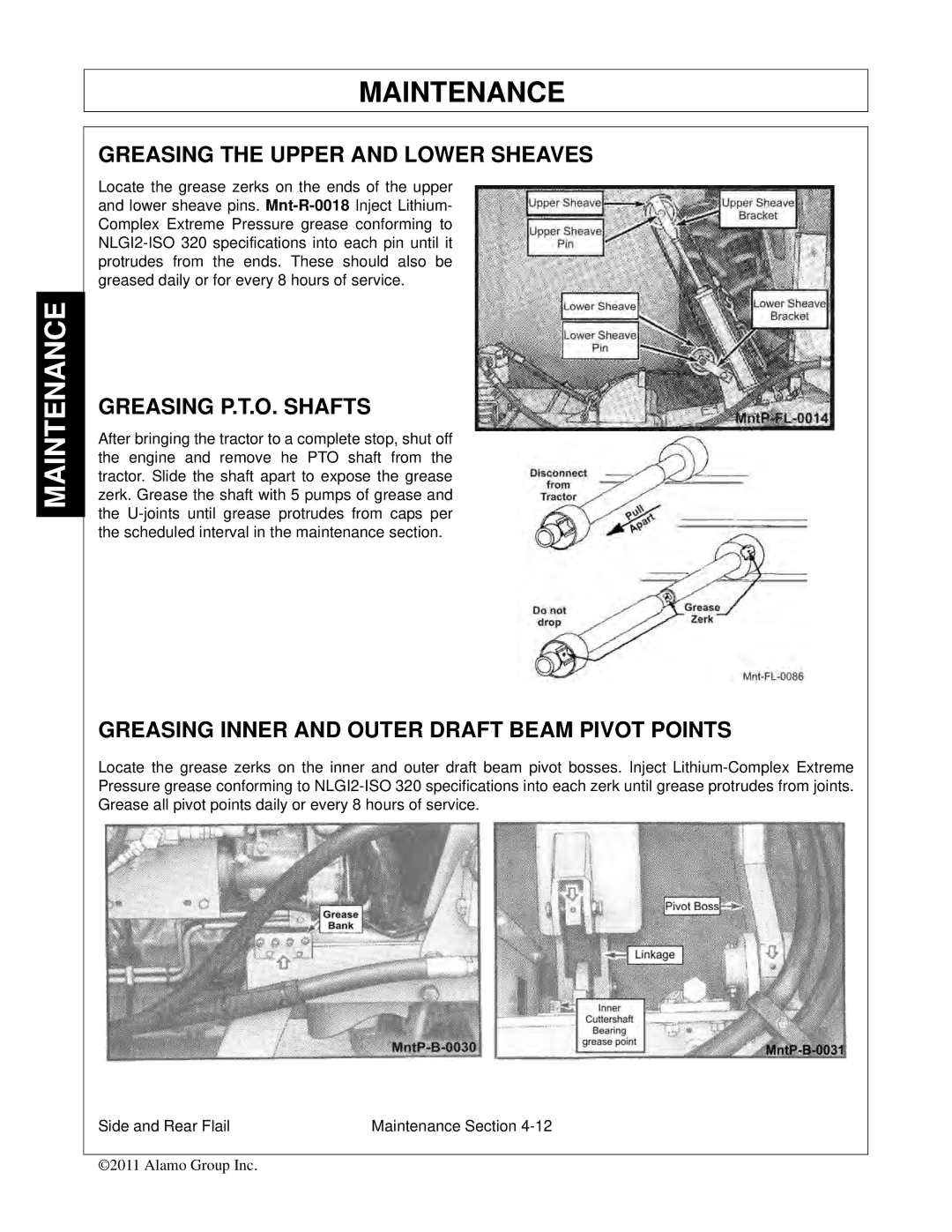

GREASING INNER AND OUTER DRAFT BEAM PIVOT POINTS

Locate the grease zerks on the inner and outer draft beam pivot bosses. Inject

Side and Rear Flail | Maintenance Section |

©2011 Alamo Group Inc.