SPLITTER GEARBOX REPAIR

NOTE: Replacing gears, shafts, bearings, and seals may not be cost effective. Purchasing a complete gear- box may be more economical.

REMOVE GEARBOX FROM CUTTER

1.Disconnect driveline from the tractor PTO and remove it from center gearbox.

2.Remove vent plug (6) and siphon gear lube from housing through this opening.

3.Disconnect and remove flex coupler drivelines from side of gearbox by:

a.Removing cap screws and hex nuts from drive- line.

b.Loosen set screws from flex coupler yoke.

c.Slide flex coupler yoke from gearbox shaft.

4.Remove the four bolts that attach gearbox to cutter and remove gearbox. Gearbox is heavy; do not attempt to move without mechanical assistance.

4.Remove oil seals (11) (to be replaced) from both sides of cross shaft (4).

5.Remove eight cap screws (3) from around gearbox cover (12) and remove cross shaft (4) from gearbox.

6.Disassemble shims (5 & 18), spacer (20), bearings (16 & 13), and crown gear (7) from cross shaft.

7.Support housing in a vise and remove bearing cones (16) by using a punch and hammer to drive bearing cone out.

8.Support cover (12) in a vise and remove bearing cups (13) by using a punch and hammer to drive bearing cone out.

9.Remove lock nut (2) from end of input shaft (14).

10.Support input housing in a handpress and push input shaft (14) out of housing.

11.Support housing in a vise and remove bearing cups (13 & 16) by using a punch and hammer to drive bearing cones out.

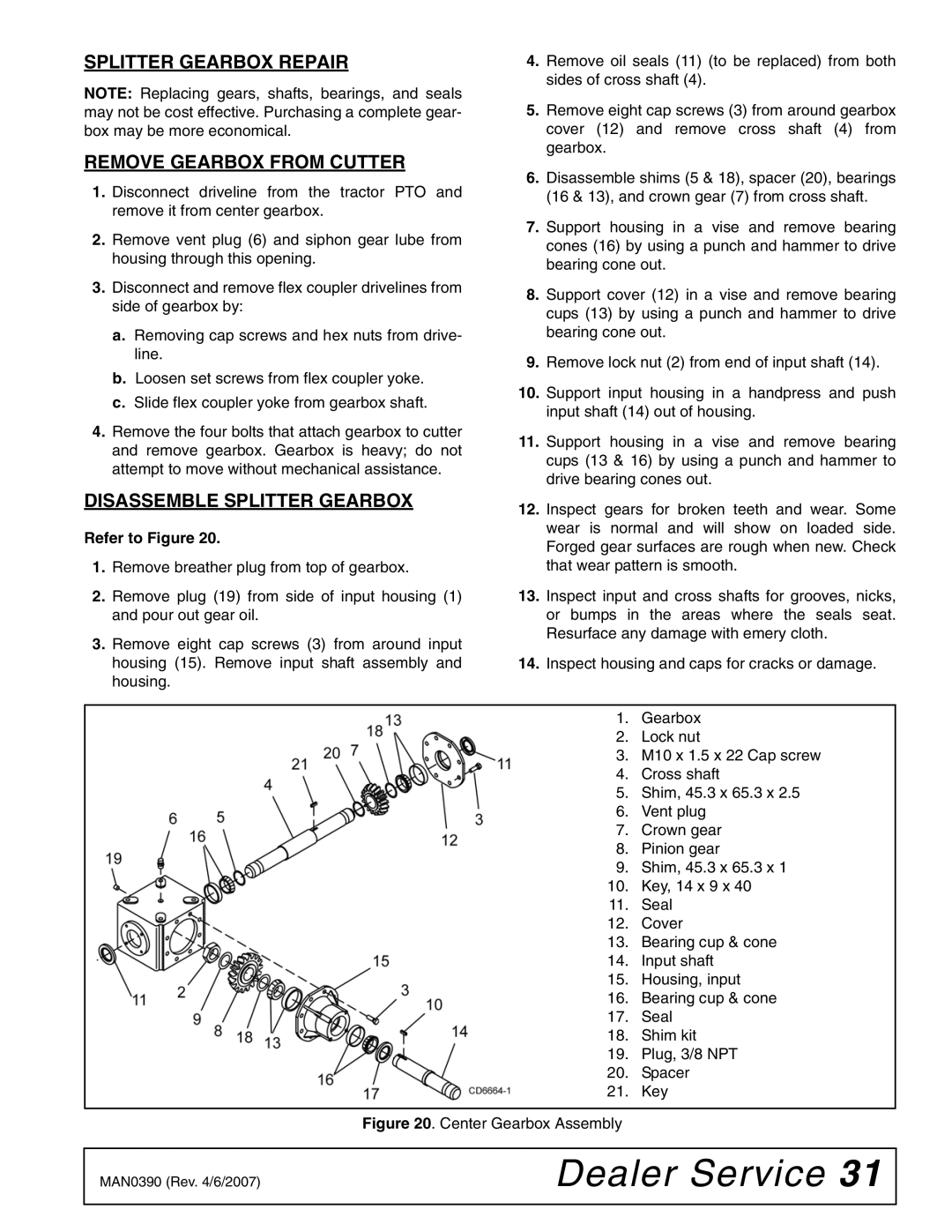

DISASSEMBLE SPLITTER GEARBOX

Refer to Figure 20.

1.Remove breather plug from top of gearbox.

2.Remove plug (19) from side of input housing (1) and pour out gear oil.

3.Remove eight cap screws (3) from around input housing (15). Remove input shaft assembly and housing.

12.Inspect gears for broken teeth and wear. Some wear is normal and will show on loaded side. Forged gear surfaces are rough when new. Check that wear pattern is smooth.

13.Inspect input and cross shafts for grooves, nicks, or bumps in the areas where the seals seat. Resurface any damage with emery cloth.

14.Inspect housing and caps for cracks or damage.

1. | Gearbox |

2. | Lock nut |

3. | M10 x 1.5 x 22 Cap screw |

4. | Cross shaft |

5. | Shim, 45.3 x 65.3 x 2.5 |

6. | Vent plug |

7. | Crown gear |

8. | Pinion gear |

9. | Shim, 45.3 x 65.3 x 1 |

10. | Key, 14 x 9 x 40 |

11. | Seal |

12. | Cover |

13. | Bearing cup & cone |

14. | Input shaft |

15. | Housing, input |

16. | Bearing cup & cone |

17. | Seal |

18. | Shim kit |

19. | Plug, 3/8 NPT |

20. | Spacer |

21. | Key |

Figure 20. Center Gearbox Assembly

MAN0390 (Rev. 4/6/2007) | Dealer Service 31 |

|

|