Zebra TTP

P1003636-002 TTP 7030 Technical Manual 10/05/2009

Contents

Programming

Interface

P1003636-002 TTP 7030 Technical Manual 10/05/2009

Introduction

About This Manual

Updating

Contacts

Subject line Emaillist

Product Presentation

Printer Exterior, Rear View

Printer Exterior, Side View

Indicators

Status Indicator

Control Board Indicators

Feed Button

Installation

Installation Considerations

Top view

Electrostatic Discharges, and Earth Currents

Ambient Light

Connecting To The Computer

Using a Serial Adapter

Connect the TTP

Fitting a serial adapter to the printer

Connecting the Power

GND

Is a power button available for the printer?

Making a Test Printout

Installing a Printer Driver

Paper Level Sensor Indicators on Roll Holder

Paper Level Sensors

Paper-near-end Sensor Connection

Operation

Installing a Paper Roll

Make sure the printer is turned on

Angle

Cut the paper in a suitable angle. See Figure

Clearing Paper Jams

Open the Print Module

Programming

Text text

How The Commands Are Described

Two-Byte Character Definitions

Therefore, the two-byte representation of 731 is

Summary Of Control Codes & Escape Sequences

50 n1 27 5 80 n1 Parameter-setting data Enquiry

27 5 Head temperature Enquiry

27 5 Bootware version Enquiry

27 5 Device ID Enquiry

Software Command Syntax

Black Mark Top-Of-Form Commands

Text Commands

Changes the alignment of text and logotypes

Left Center Right

Selects font

Selects normal font font ESC ! 4 selects font

Selects font ESC ! 5 selects font

Turns OFF Italics Normal Turns on Italics

ESC T n1 Reversed/Inversed Text

ESC w n1

Commands, are not cancelled

Overprint the O

ESC d n1 Make n Linefeeds

Barcode Commands

Samples of barcodes

Specifies the bar code field No -15. Bar code fields may be

Specified in any order

Add-on. Two of five characters are allowed of the add-on

But other values than 0 to 15 are ignored

N2 . . . nx Specifies bar code data bytes

Must be placed at the end of the bar code data

Error level, 0=auto, 1=Level0, 2=Level1, etc

Columns

Dot Height, sets mow many pixel lines each row consists

Graphics Commands

Determines the number of bytes. Range

ESCr000000000000001193000024003

ESC g n1 Print Logotype

Run presenter

Print Commands

Form feed Clear presenter

Print buffer full Press on FF-button

ESC j n1 Paper Reverse

To auto

Cut And Present Commands

You can also use RS together with the paper advance command

Gives a cut & eject after the last text line

Ejects the presented

Retracts the presented

ENQ

System Related Commands

Erases all logotypes stored in the flash Prom

Erases all fonts stored in the flash Prom

See Default Parameter Settings on

Set several parameters at once

Status Reporting Commands

Paper-near-end Enquiry

Send

Read

Sensor Status

Readn Where n can be ‘A’ Ascii or 41 hex or 65 dec

That is, a response with the value 129 indicates version

That is, a response with the value 130 indicates version

Under Summary Of Parameter Settings on

One-byte marker. Range 1h to 255h

Font Loading

File Format

Character bitmap data

Logotypes

Loading

All logotypes are erased with the ESC&L command

Printing

Status Reporting

Default Parameter Settings

Programming

Default Parameter Settings

Default Value

Summary Of Parameter Settings

Serial Interface Set-Up

Xon / Xoff

Select what handshaking to use on the serial interface

No flow control

Hardware

Parallel Port Setup

No, paper out and error signals are not disabled

Yes, paper out and error signals are disabled

Current consumption

Print Setup

Disable the loop

Cm loop

Burn pulse

Controls what the printer does with buffered data

Burn pulse + history

Burn pulses + history

LF = Ignored

Black mark synchronization enabled

CR = Ignored

On the paper

Fixed Document Mode. Shorter documents will automatically

Contents printouts shorter than the value specified by

Determines what should control the page length

Be extended, while longer documents will be divided into

Fixed Document Mode

Length P37 P38

Feeds 50 mm between black mark and cut

Sets max black mark length to 5 mm

Sets min black mark length to 4 mm

Add 30-mm top margin

Do nothing when new page is printed. Auto-eject and retract

Eject page when new page is printed. Retract disabled

Retract page when new page is printed

Will be retracted. Range 1-30, 1 step = 10 s

No indication

Off

Automatic Distance Calculation

Paper Near End indication

Default Parameter Settings

Setup

Printable Area

N43 N44

Aligning Preprint And Thermal Print

Recommended black mark size and position

Setup

Enables/disables black mark check

Parameters Used

Garbage, Black Mark and Out of Paper Detection

Parameter n41 and n42 -Black Mark Cut Offset

Specified by the ESC x command

Send Text and graphics

Send RS Cuts and ejects the printout

Simple Calibration Process

Black-Mark Sensing from Within Windows

Interface

+ Data

Cable power

USB Interface

Cable ground

Setup Options

Serial Option, TTP

Interface

Maintenance

Fault Finding

Fault Finding

101

Cleaning The Print Head

Printer with retract

Fitting a Shutter

Firmware

Specifications

Print Data

None, Odd or Even

Command Code Modes Non-Windows Applications

Basic Character Set

108

109

Bar Codes Non-Windows Applications

Paper Handling

Printer Dimensions

Environmental Conditions

General

Paper Specification

Miscellaneous

Thermal coating

Perforation

Preprinting

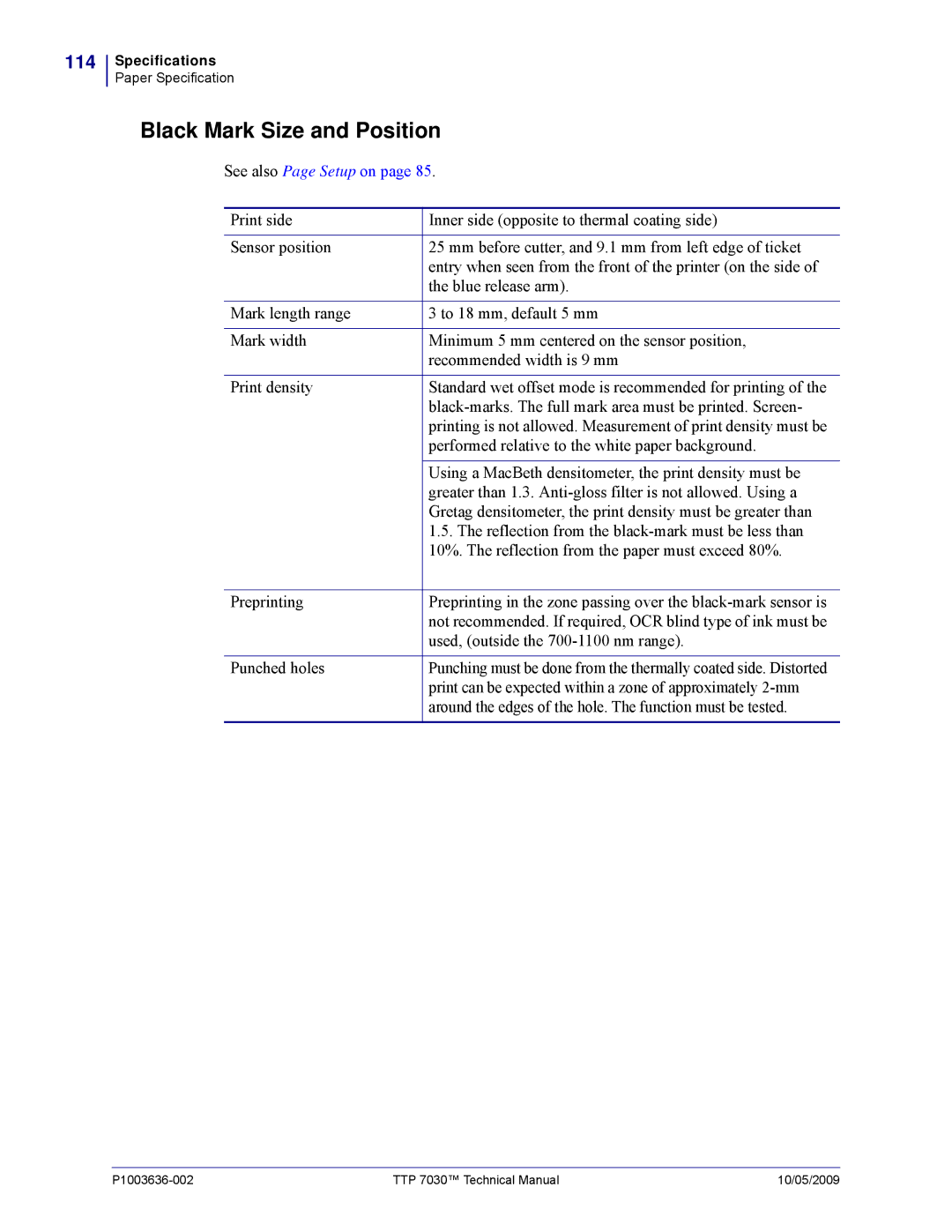

Black Mark Size and Position

Print can be expected within a zone of approximately 2-mm

Around the edges of the hole. The function must be tested

Accessories

Part Number List

Printers

116

117

Roll Holders

Roll Holder for Paper Rolls up to 150 mm

119

120

中国 RoHS 材料声明 China RoHS Material Declaration

表示该部件的某一均质材料中的有毒有害物质的含量超出 SJ/Txxx-2006标准规定的限量要求。

122

Index

Numerics

Index

Index

Connector Port

USB

Page

Zebra Technologies Europe Limited