59

58

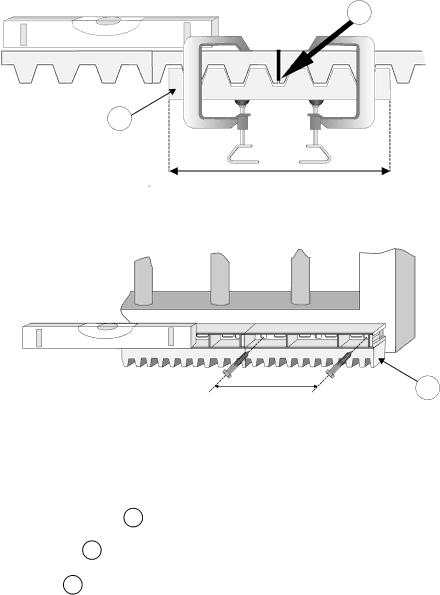

200 - 300mm

LEVEL |

200mm

60

MOUNTING RACK CONTINUED

-A simple way of ensuring correct pitch spacing when joining steel rack is to clamp a small offcut 58 between the two pieces.

-Check that weld 59 does not foul with meshing surfaces.

-If RAZ ™ rack 60 is used, then start installing from the right hand side of the gate working towards the LHS. Use fastening screws e.g. “TEK” screws at least every 200mm.

12