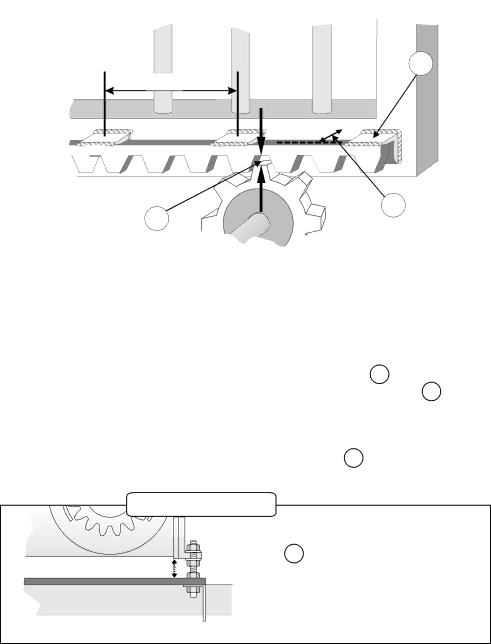

55

±300 mm

56

57

MOUNTING RACK

-Attach steel rack to gate using 25x25x2mm angle brackets 55 . Distance between centerline of rack and edge of gate should be 20mm (see 56 ).

-For best results support rack every 300mm.

-Rack must be mounted level with a 2 - 3mm clearance 57 .

USEFUL TIP

λ Raise gearbox by an additional 3mm.

λ P u t g e a r b o x i n t o m a n u a l m o d e (see 37 on page 22)

λ Mesh rack and pinion fully and mount rack.

Slide gate backwards and forwards ensuring that rack mesh is smooth and never tight.

λ Drop gearbox by 3mm to create 3mm tooth clearance.

11