x 2

Central Heating |

|

| Domestic Hot Water |

|

|

| ||

Temperature Control | Fig. 105 | Temperature Control |

|

|

| |||

Selector Switch | Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

|

| 2 |

| 12 |

|

|

|

|

|

| 3 |

| 11 |

|

|

|

|

|

| 4 |

|

| 10 |

Reset |

|

|

| 2 | 5 |

|

| 9 |

|

|

|

| PM |

|

|

| |

|

|

|

| 3 |

|

| 8 | |

|

|

|

| 7 |

|

| 7 | |

|

|

|

|

| 8 |

|

| AM |

|

|

| 0 | 4 | 9 |

| 0 | 5 |

|

|

|

| bar | 10 |

|

| 4 |

|

|

|

|

| 11 |

| 3 |

|

|

|

|

|

| 12 | 1 | 2 |

|

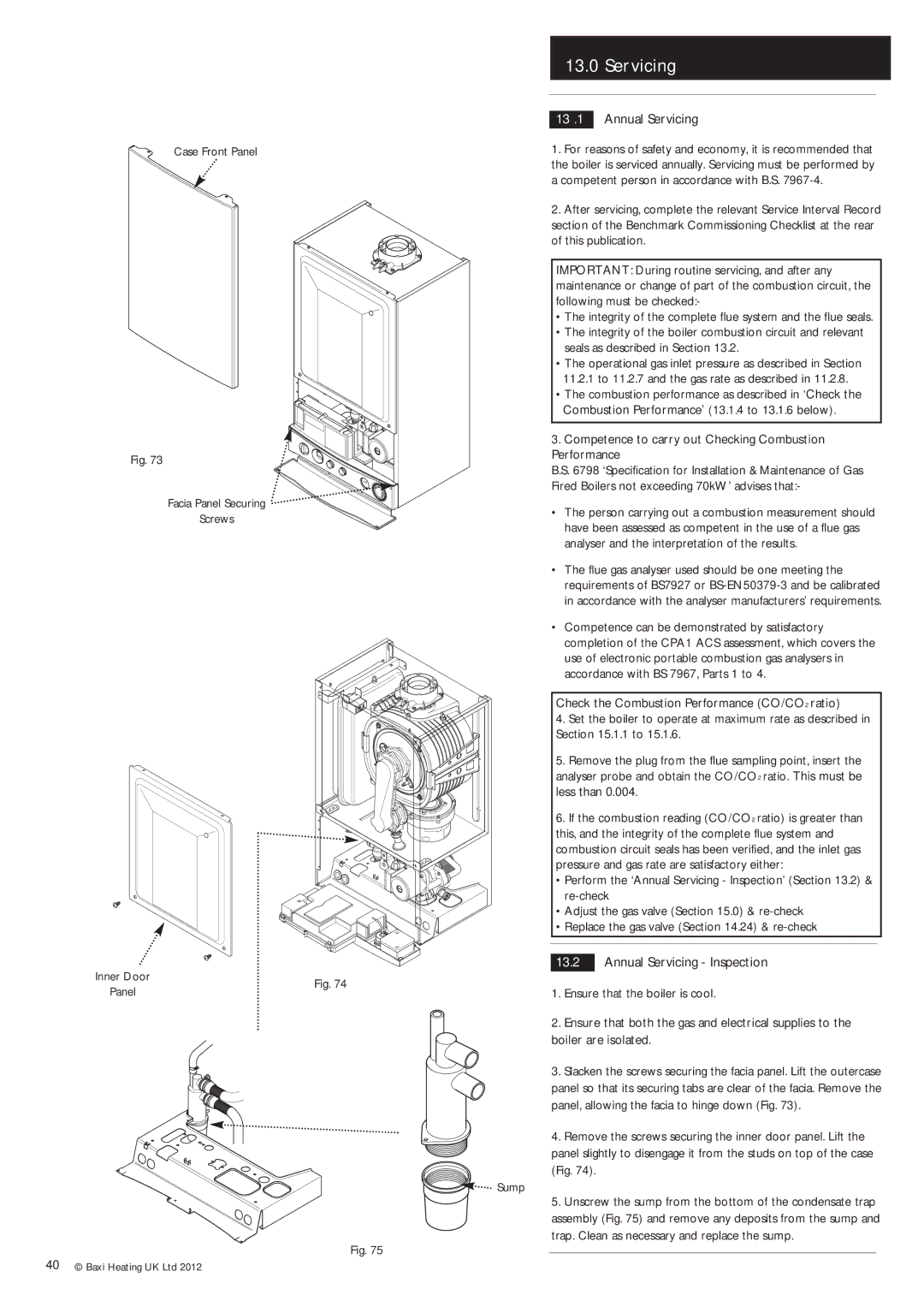

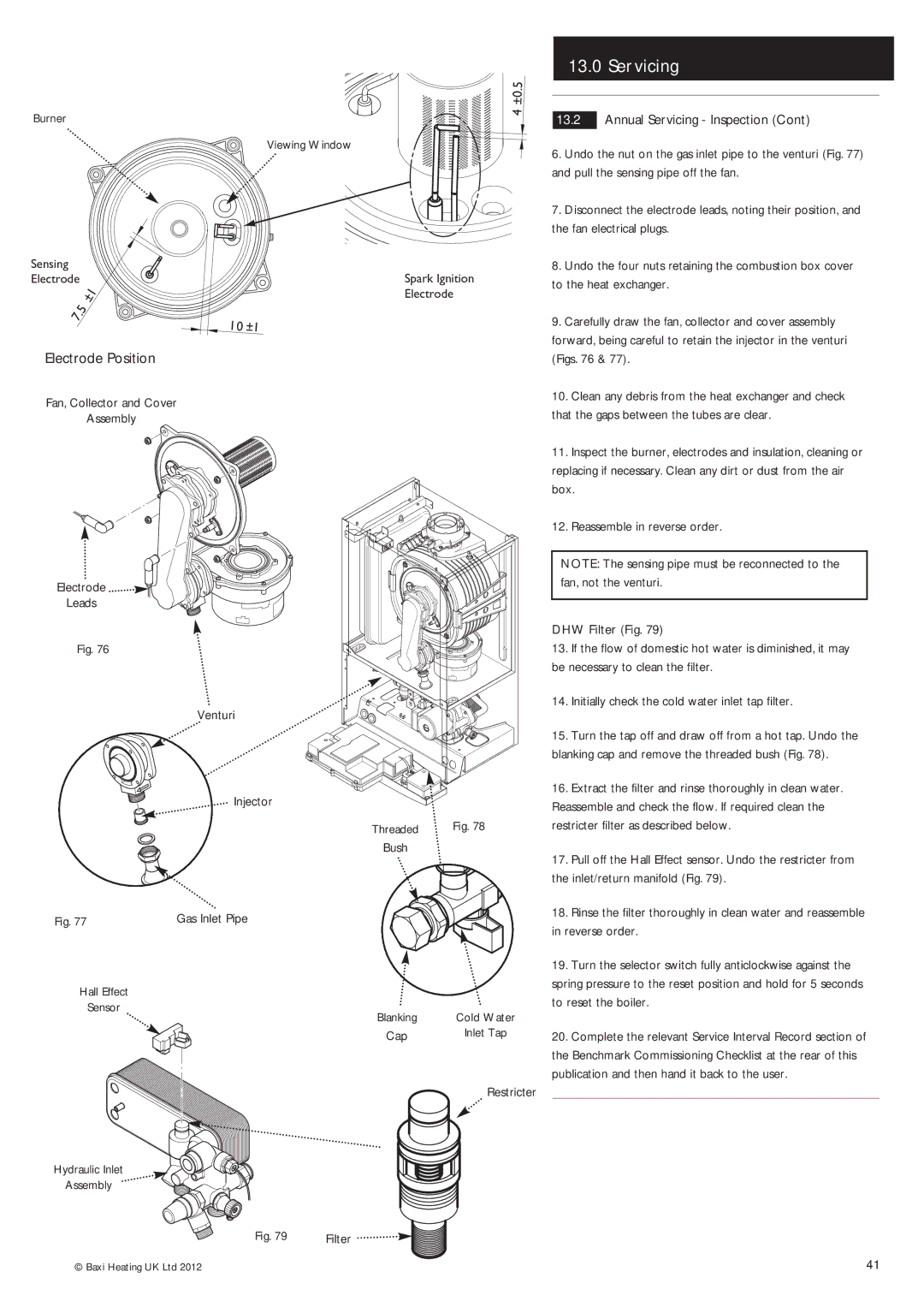

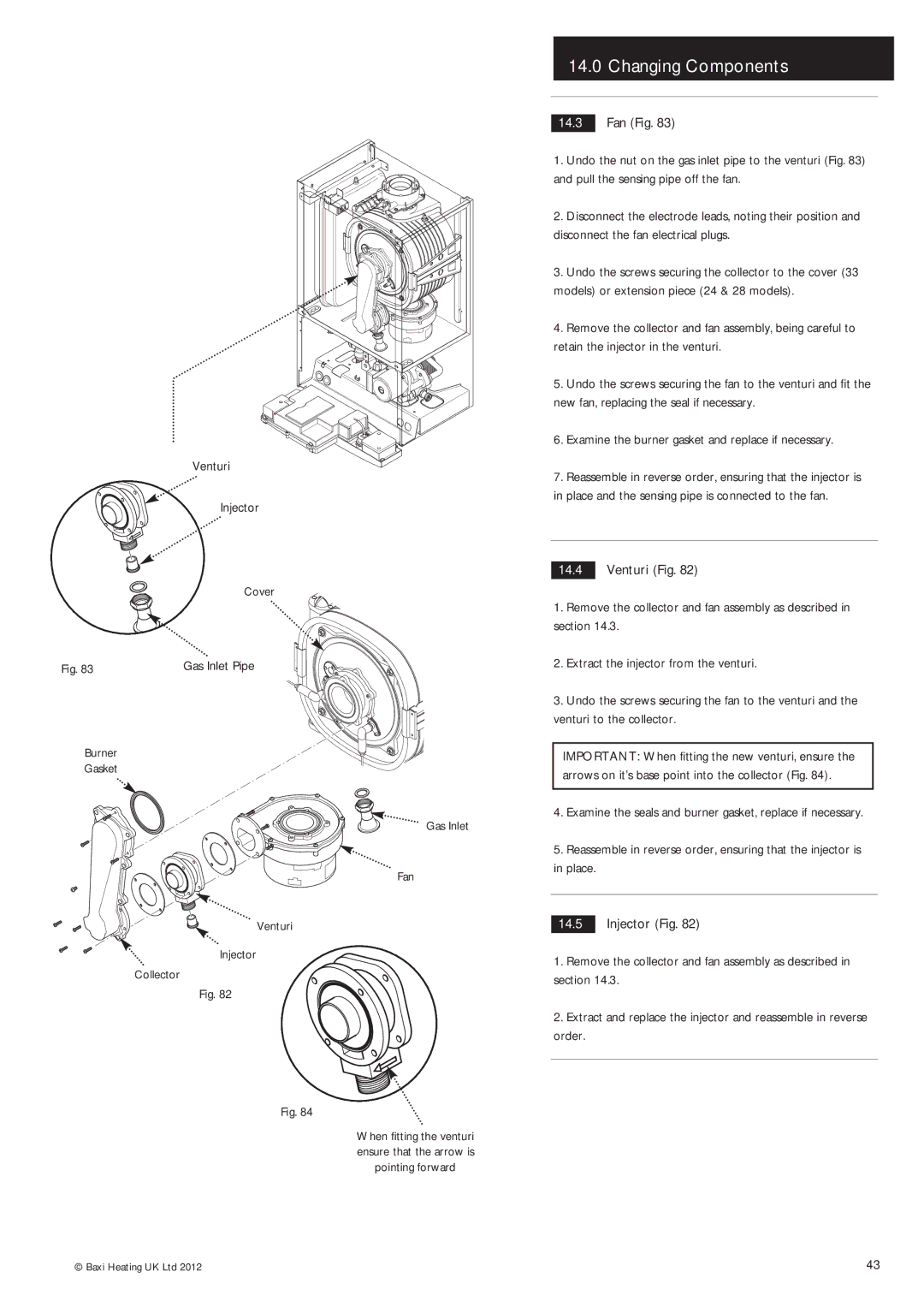

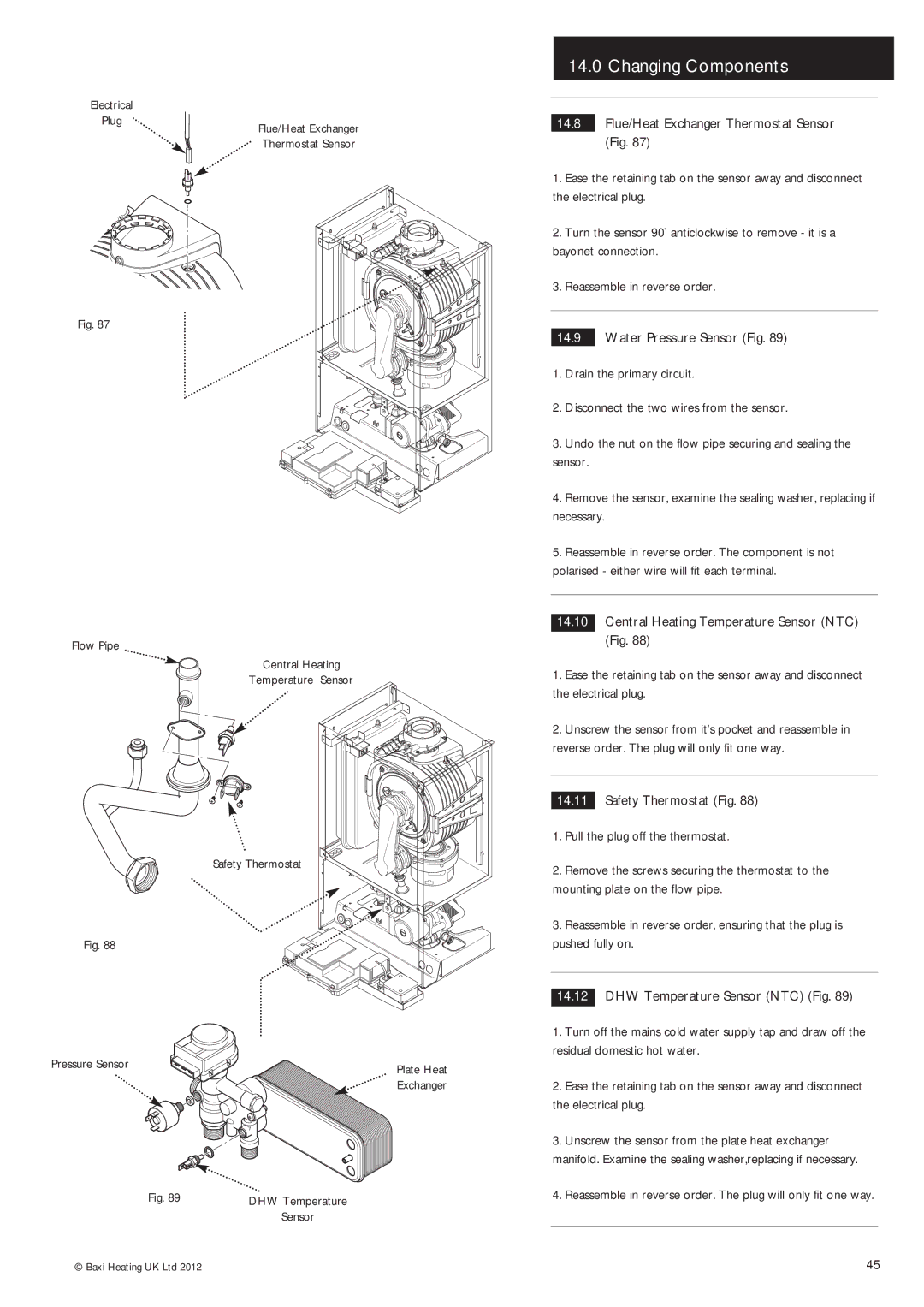

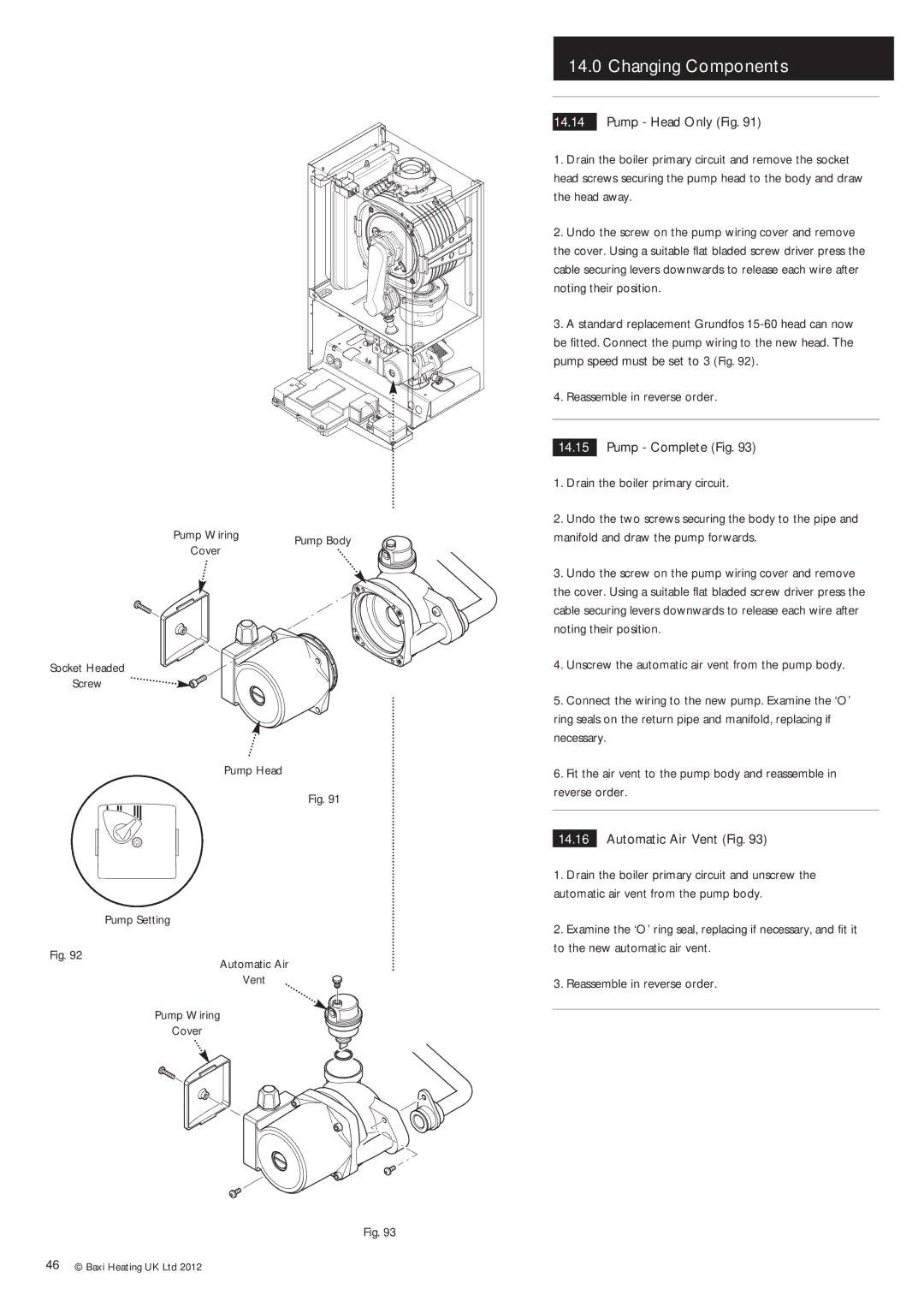

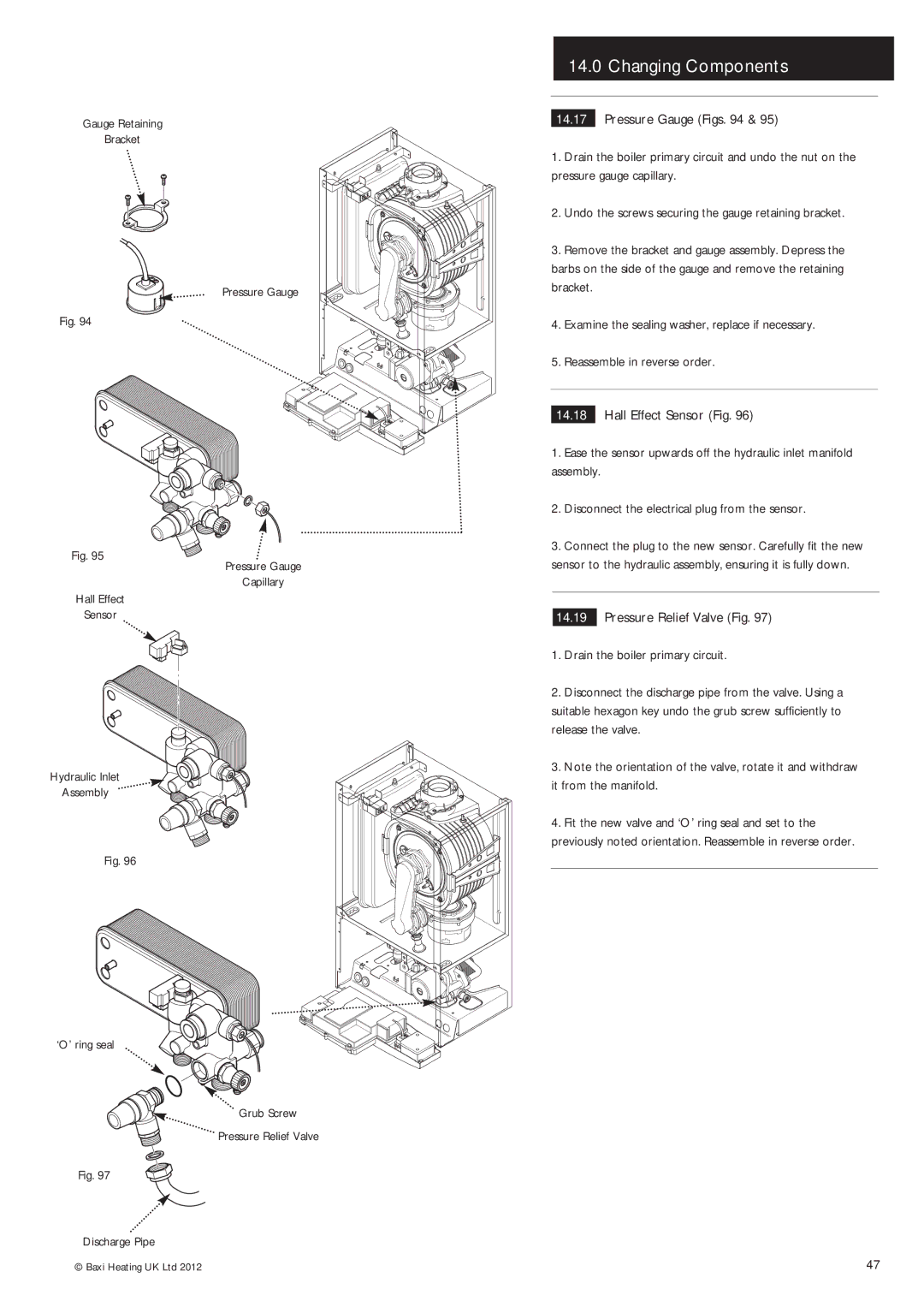

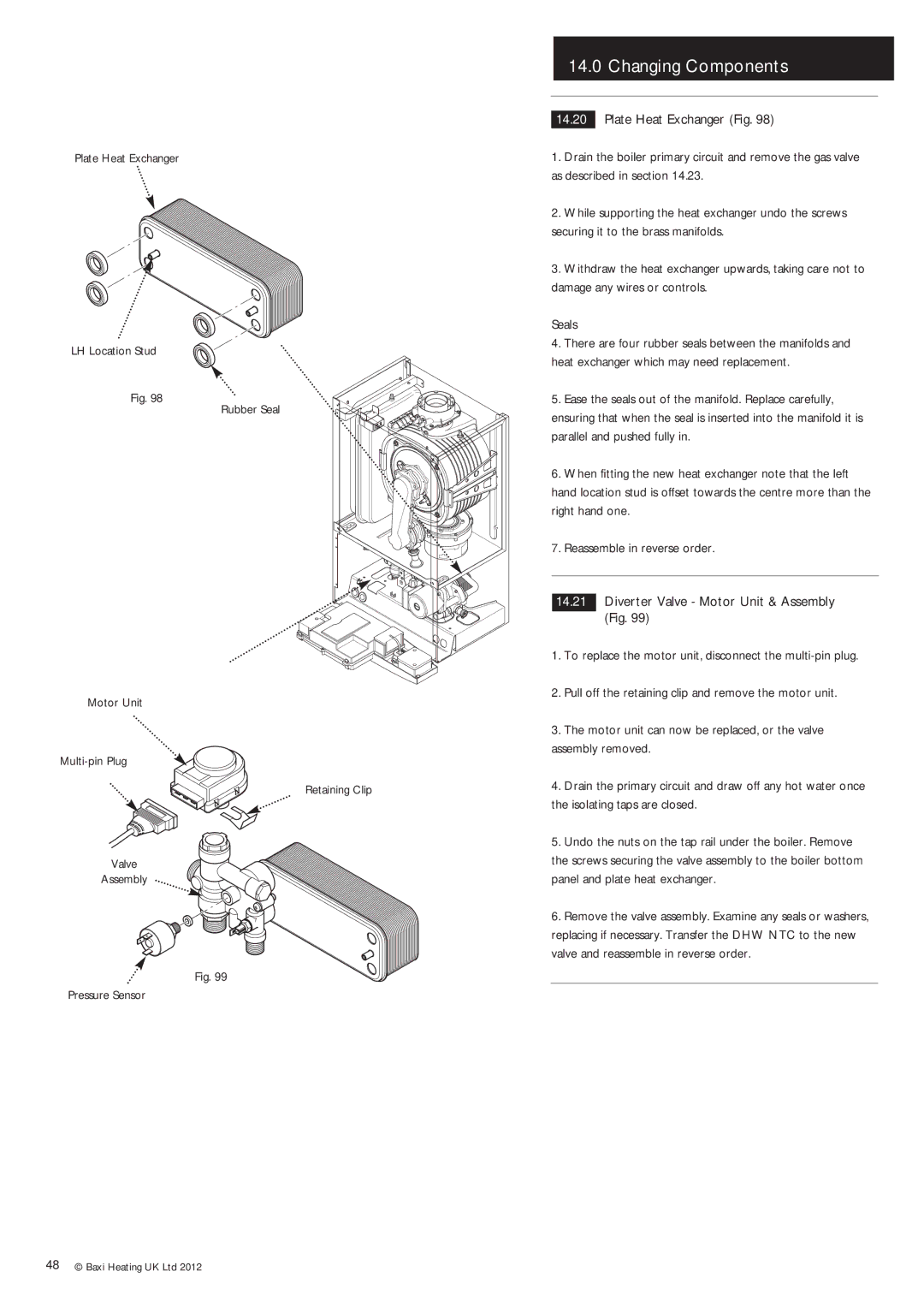

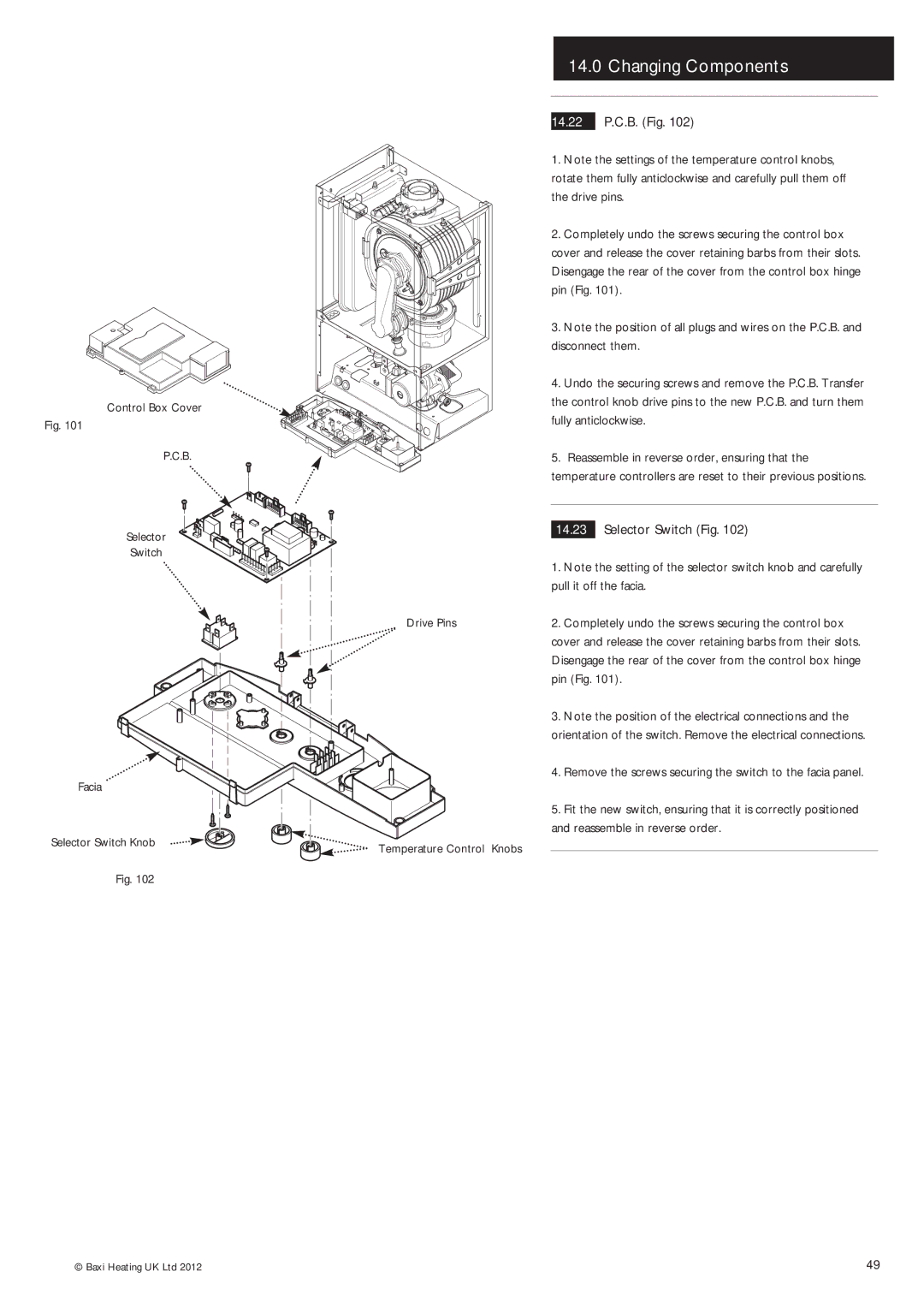

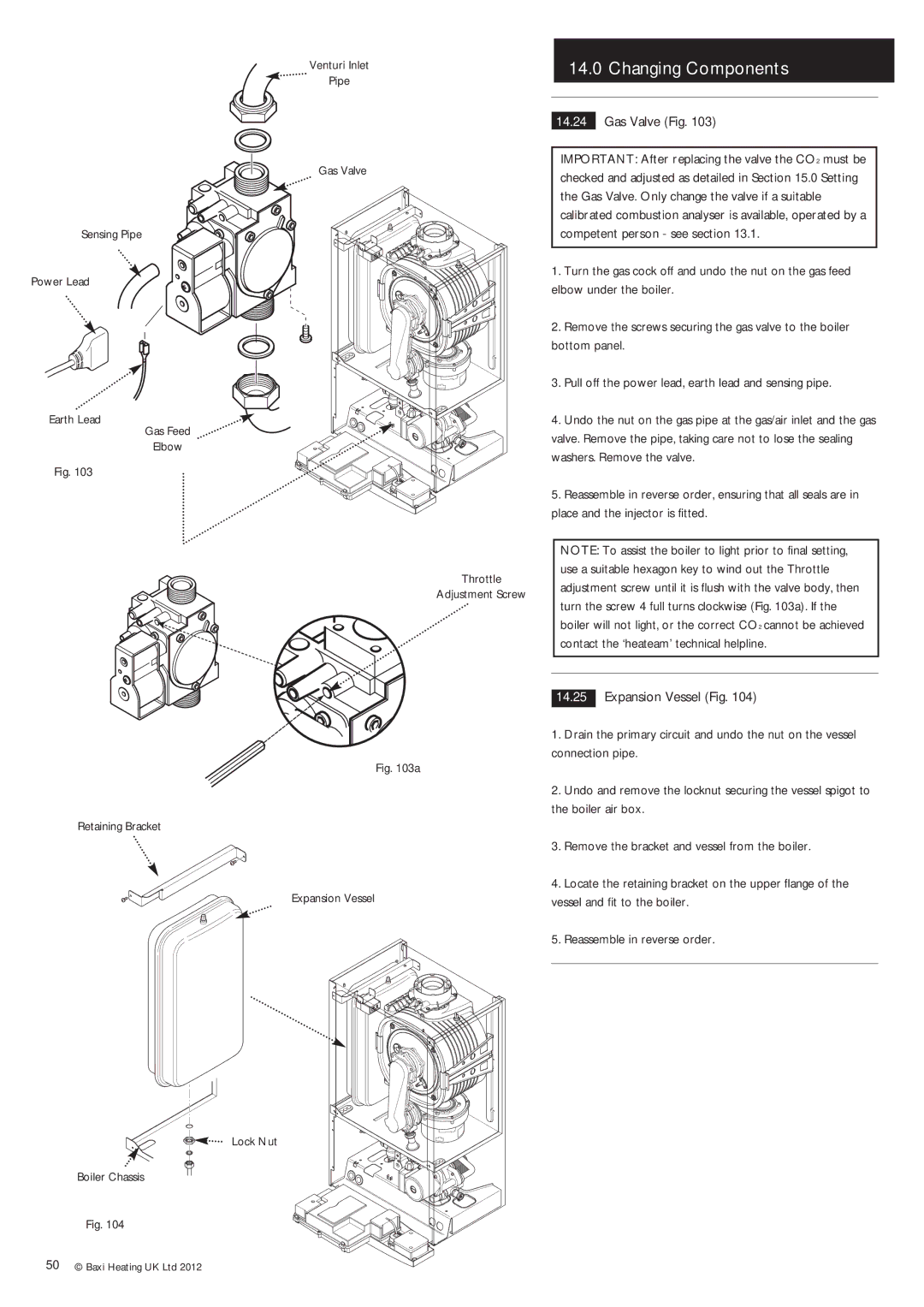

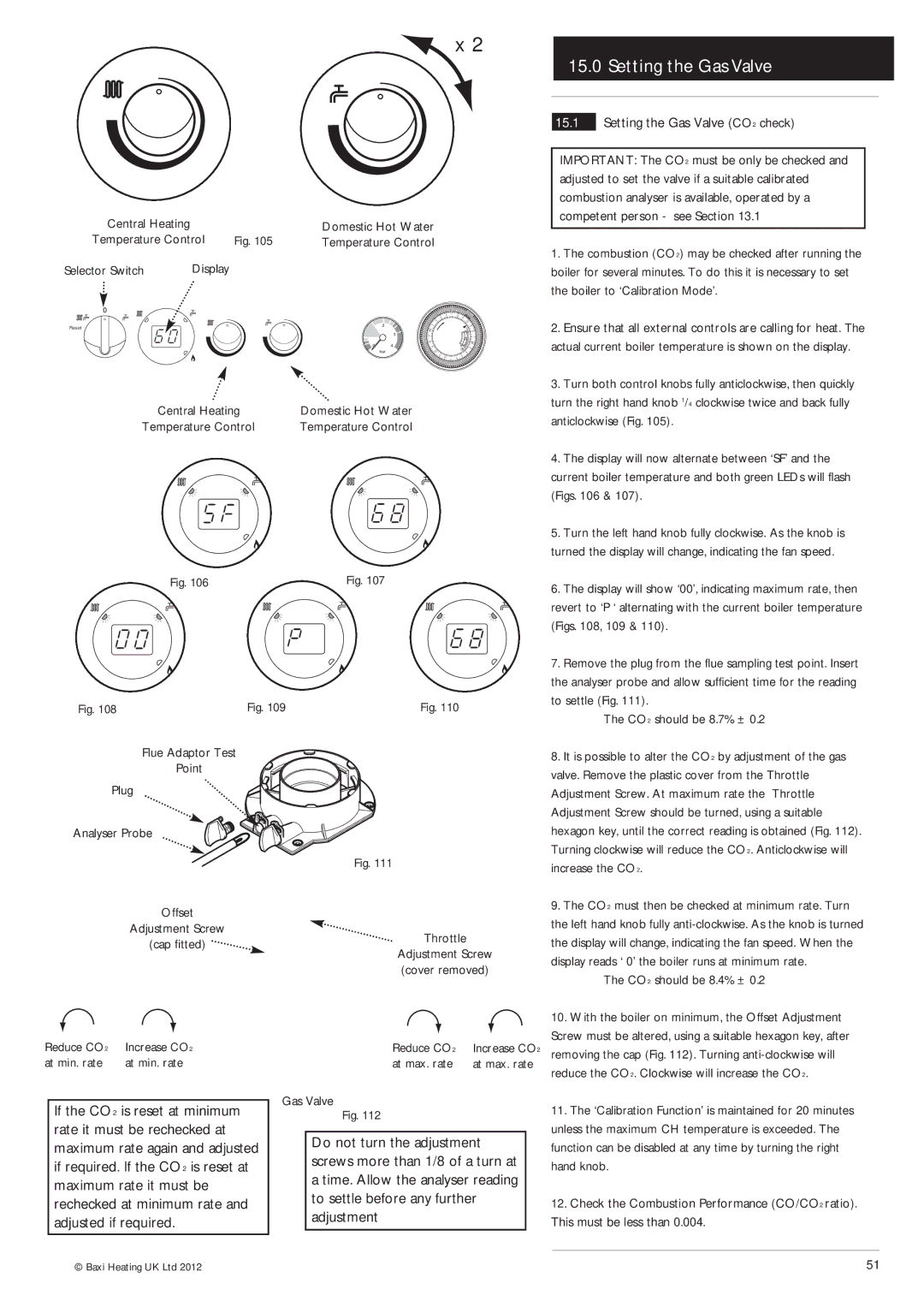

15.0Setting the Gas Valve

15.1Setting the Gas Valve (CO2 check)

IMPORTANT: The CO2 must be only be checked and adjusted to set the valve if a suitable calibrated combustion analyser is available, operated by a competent person - see Section 13.1

1.The combustion (CO2) may be checked after running the boiler for several minutes. To do this it is necessary to set the boiler to ‘Calibration Mode’.

2.Ensure that all external controls are calling for heat. The actual current boiler temperature is shown on the display.

Central Heating | Domestic Hot Water |

Temperature Control | Temperature Control |

Fig. 106 | Fig. 107 |

Fig. 108 | Fig. 109 | Fig. 110 |

Flue Adaptor Test

Point

Plug

Analyser Probe

Fig. 111

Offset |

| |

Adjustment Screw | Throttle | |

(cap fitted) | ||

Adjustment Screw | ||

| ||

| (cover removed) |

3.Turn both control knobs fully anticlockwise, then quickly turn the right hand knob 1/4 clockwise twice and back fully anticlockwise (Fig. 105).

4.The display will now alternate between ‘SF’ and the current boiler temperature and both green LEDs will flash (Figs. 106 & 107).

5.Turn the left hand knob fully clockwise. As the knob is turned the display will change, indicating the fan speed.

6.The display will show ‘00’, indicating maximum rate, then revert to ‘P ‘ alternating with the current boiler temperature (Figs. 108, 109 & 110).

7.Remove the plug from the flue sampling test point. Insert the analyser probe and allow sufficient time for the reading to settle (Fig. 111).

The CO2 should be 8.7% ± 0.2

8.It is possible to alter the CO2 by adjustment of the gas valve. Remove the plastic cover from the Throttle Adjustment Screw. At maximum rate the Throttle Adjustment Screw should be turned, using a suitable hexagon key, until the correct reading is obtained (Fig. 112). Turning clockwise will reduce the CO2. Anticlockwise will increase the CO2.

9.The CO2 must then be checked at minimum rate. Turn the left hand knob fully

The CO2 should be 8.4% ± 0.2

Reduce CO2 | Increase CO2 |

at min. rate | at min. rate |

|

| 10. With the boiler on minimum, the Offset Adjustment |

Reduce CO2 | Increase CO2 | Screw must be altered, using a suitable hexagon key, after |

removing the cap (Fig. 112). Turning | ||

at max. rate | at max. rate | reduce the CO2. Clockwise will increase the CO2. |

|

|

If the CO2 is reset at minimum rate it must be rechecked at maximum rate again and adjusted if required. If the CO2 is reset at maximum rate it must be rechecked at minimum rate and adjusted if required.

Gas Valve

Fig. 112

Do not turn the adjustment screws more than 1/8 of a turn at a time. Allow the analyser reading to settle before any further adjustment

11.The ‘Calibration Function’ is maintained for 20 minutes unless the maximum CH temperature is exceeded. The function can be disabled at any time by turning the right hand knob.

12.Check the Combustion Performance (CO/CO2 ratio). This must be less than 0.004.

© Baxi Heating UK Ltd 2012 | 51 |