x 2

Central Heating |

| Domestic Hot Water |

|

|

| |||

Temperature Control | Fig. 66 | Temperature Control |

|

|

| |||

Selector Switch | Display |

|

|

|

|

|

|

|

|

|

|

|

| 2 | 1 | 12 |

|

|

|

|

|

| 3 |

| 11 |

|

|

|

|

|

| 4 |

|

| 10 |

Reset |

|

|

| 2 | 5 |

|

| 9 |

|

|

|

| PM |

|

|

| |

|

|

|

| 3 |

|

| 8 | |

|

|

|

| 7 |

|

| 7 | |

|

|

|

|

| 8 |

|

| AM |

|

|

| 0 | 4 | 9 |

| 0 | 5 |

|

|

|

| bar | 10 |

|

| 4 |

|

|

|

|

| 11 | 1 | 3 |

|

|

|

|

|

| 12 | 2 |

| |

| Central Heating | Domestic Hot Water |

|

|

|

| ||

Temperature Control | Temperature Control |

|

|

|

| |||

Gas Pressure

Test Point

Fig. 66a

Gas Valve

Fig. 67 | Fig. 68 |

|

Fig. 69

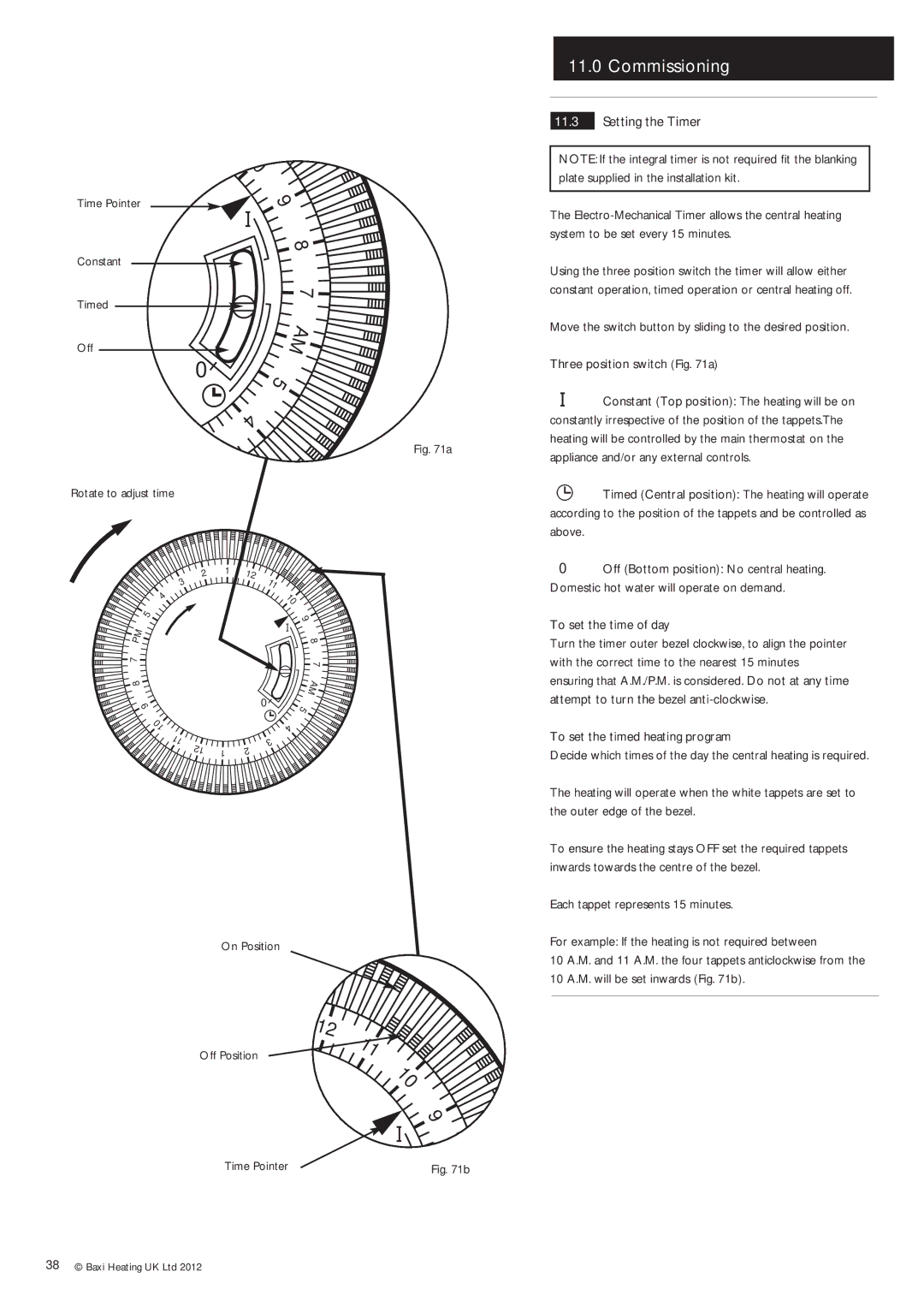

Fig. 70 | Fig. 71 |

|

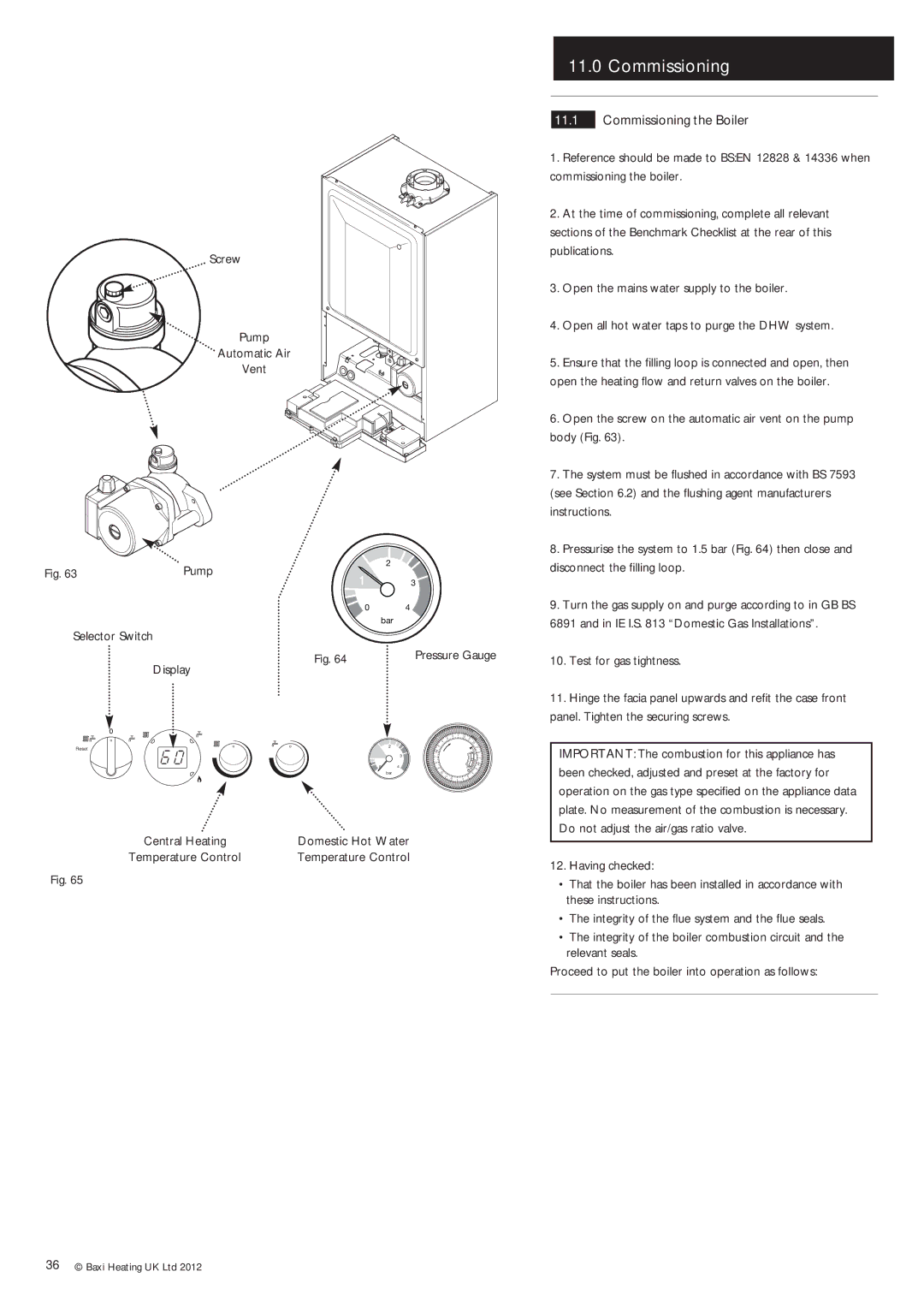

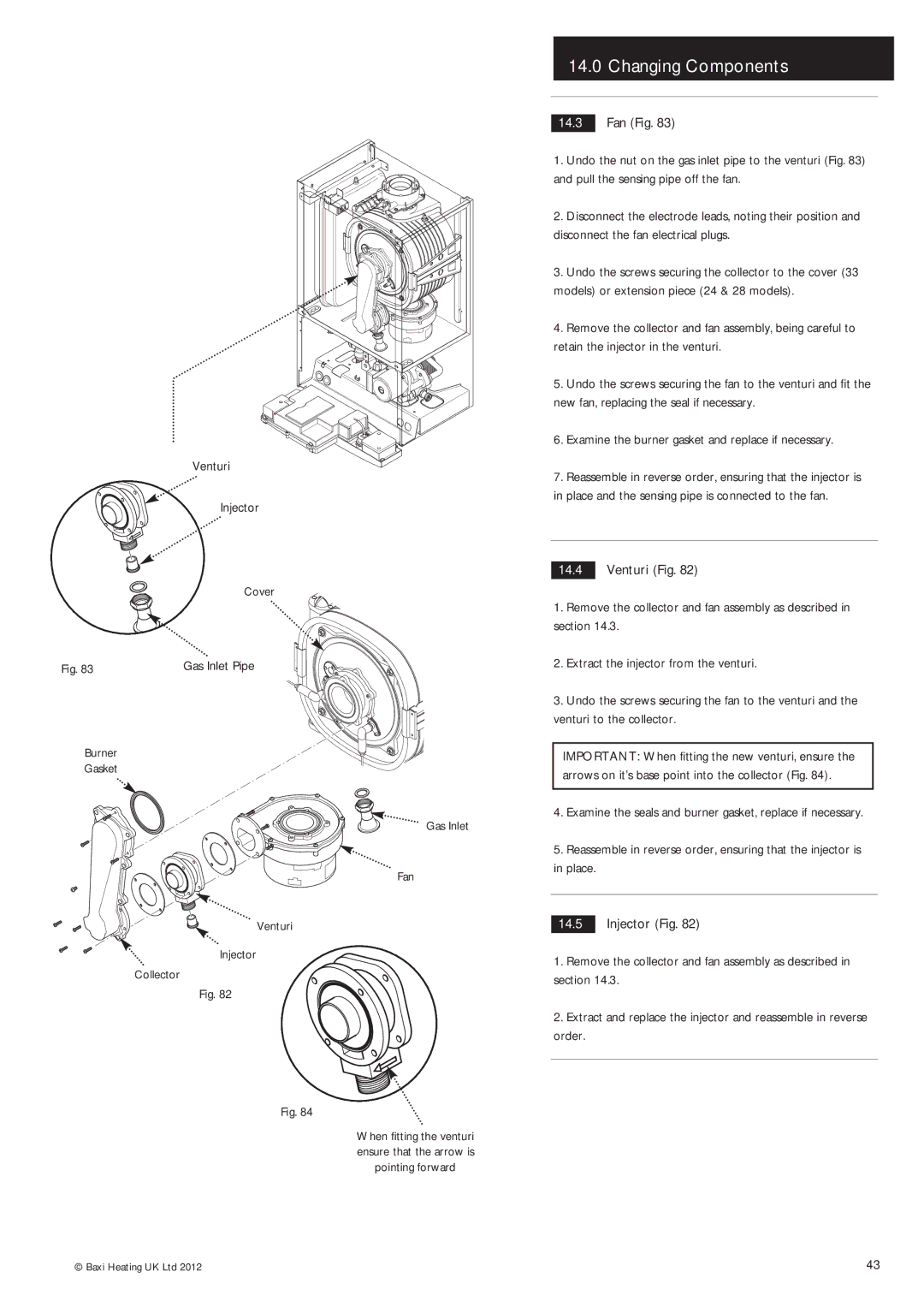

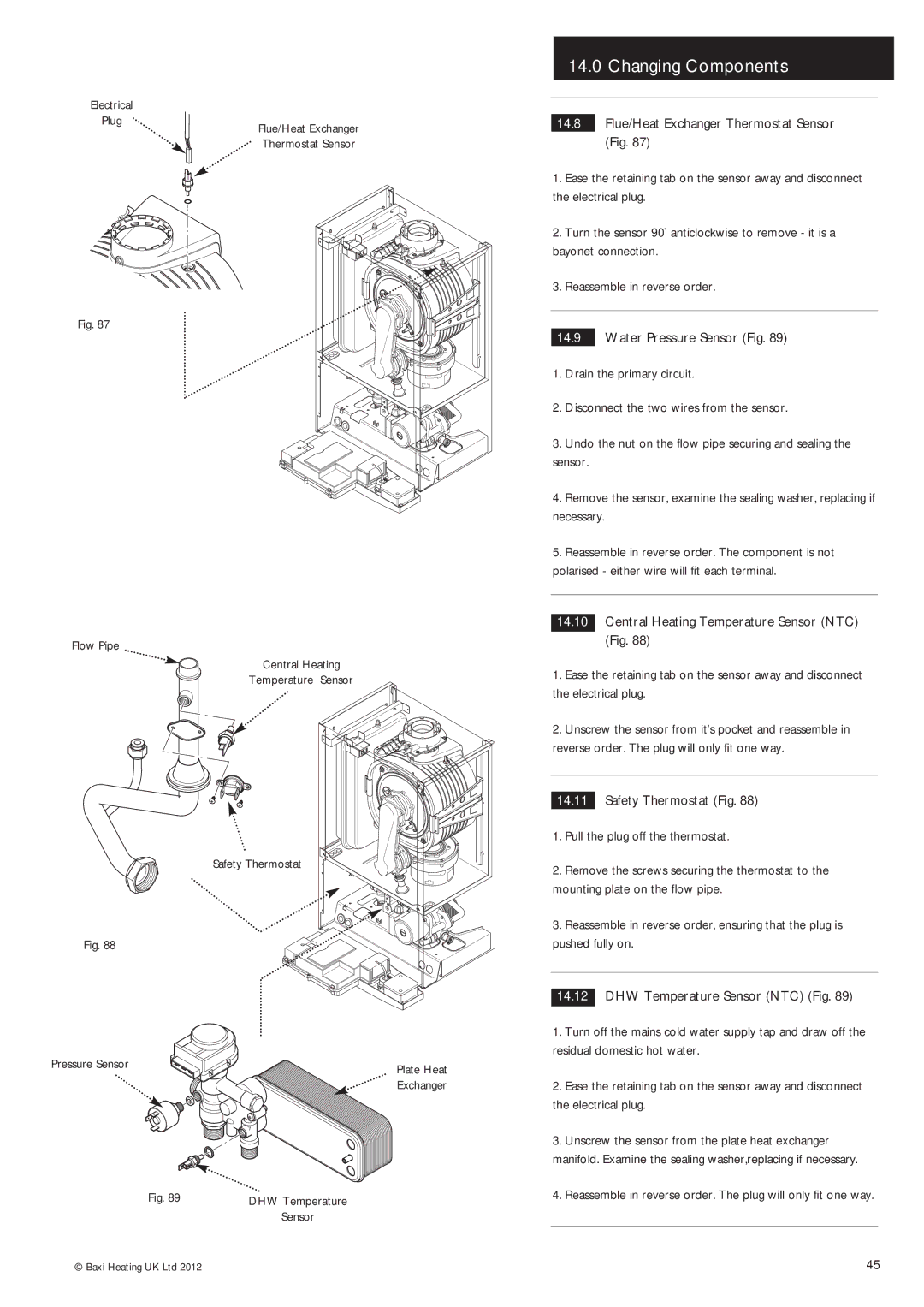

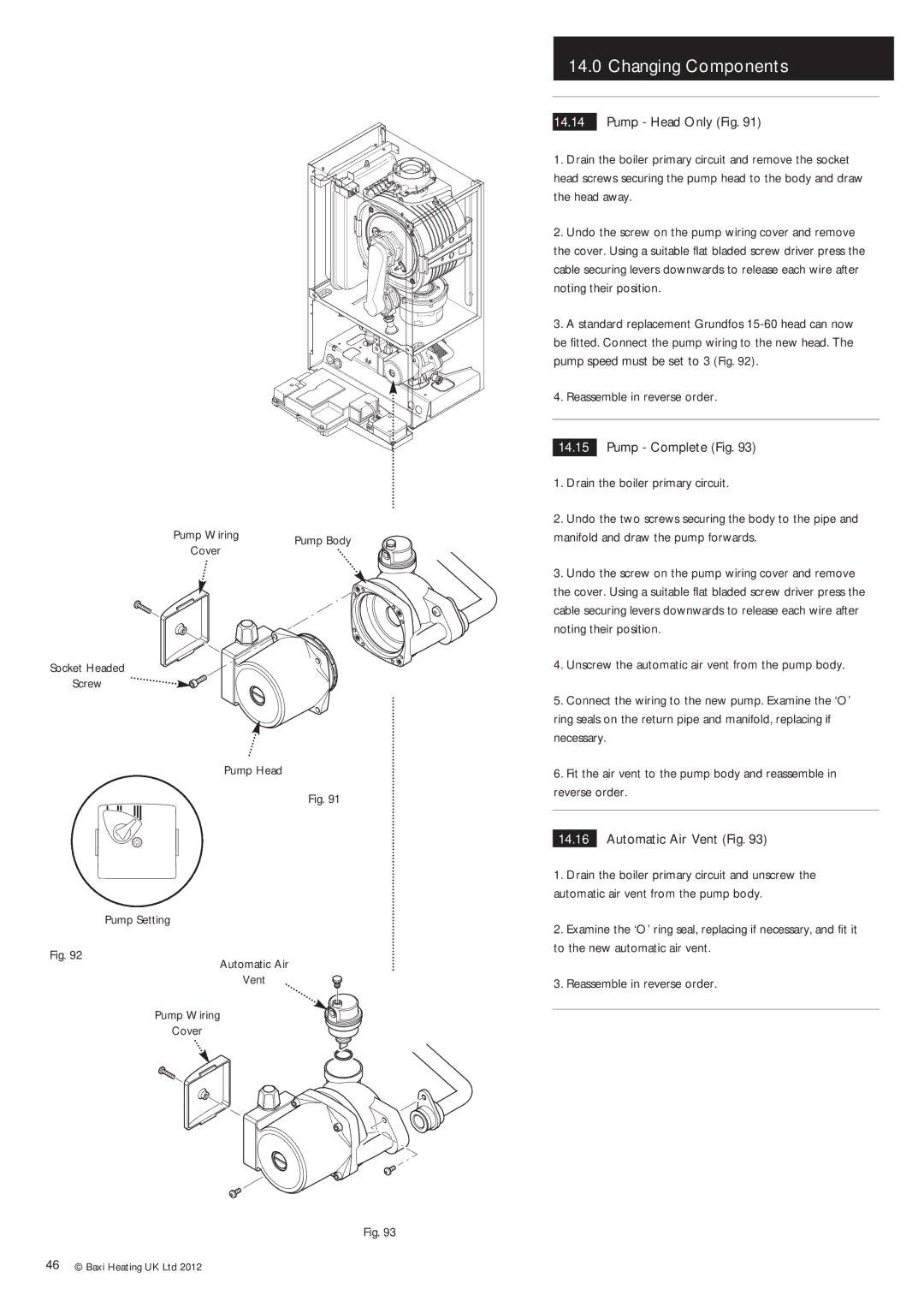

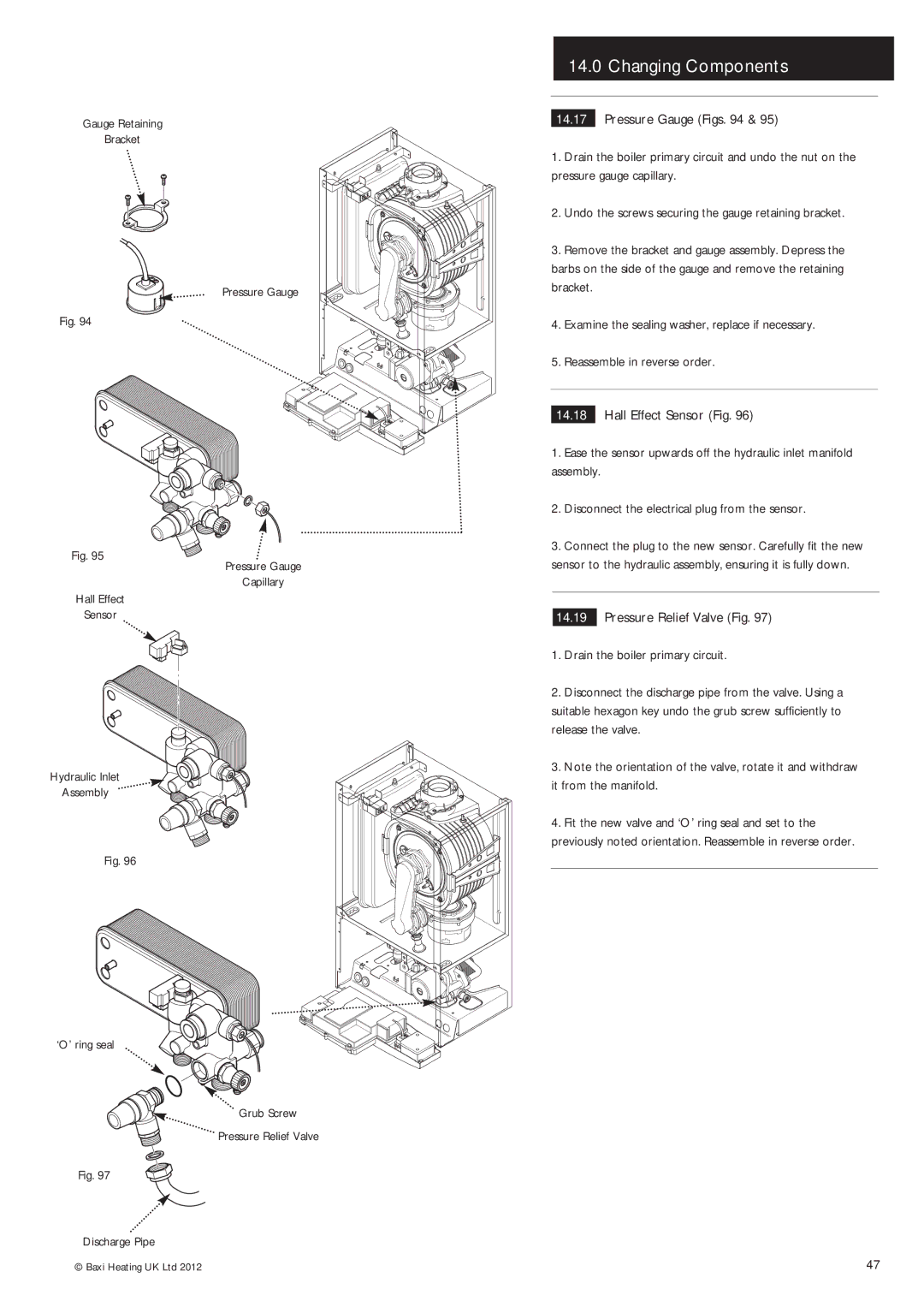

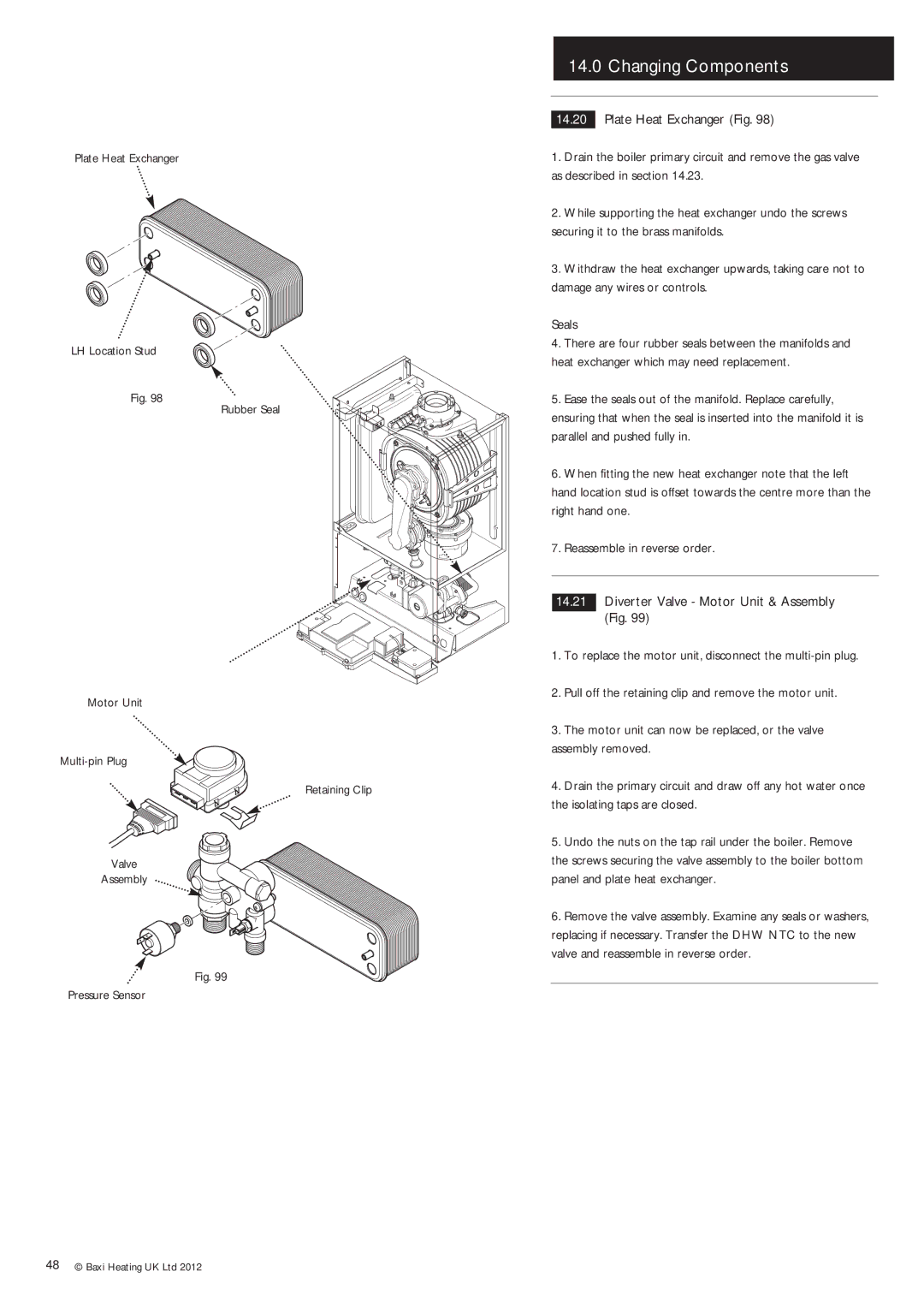

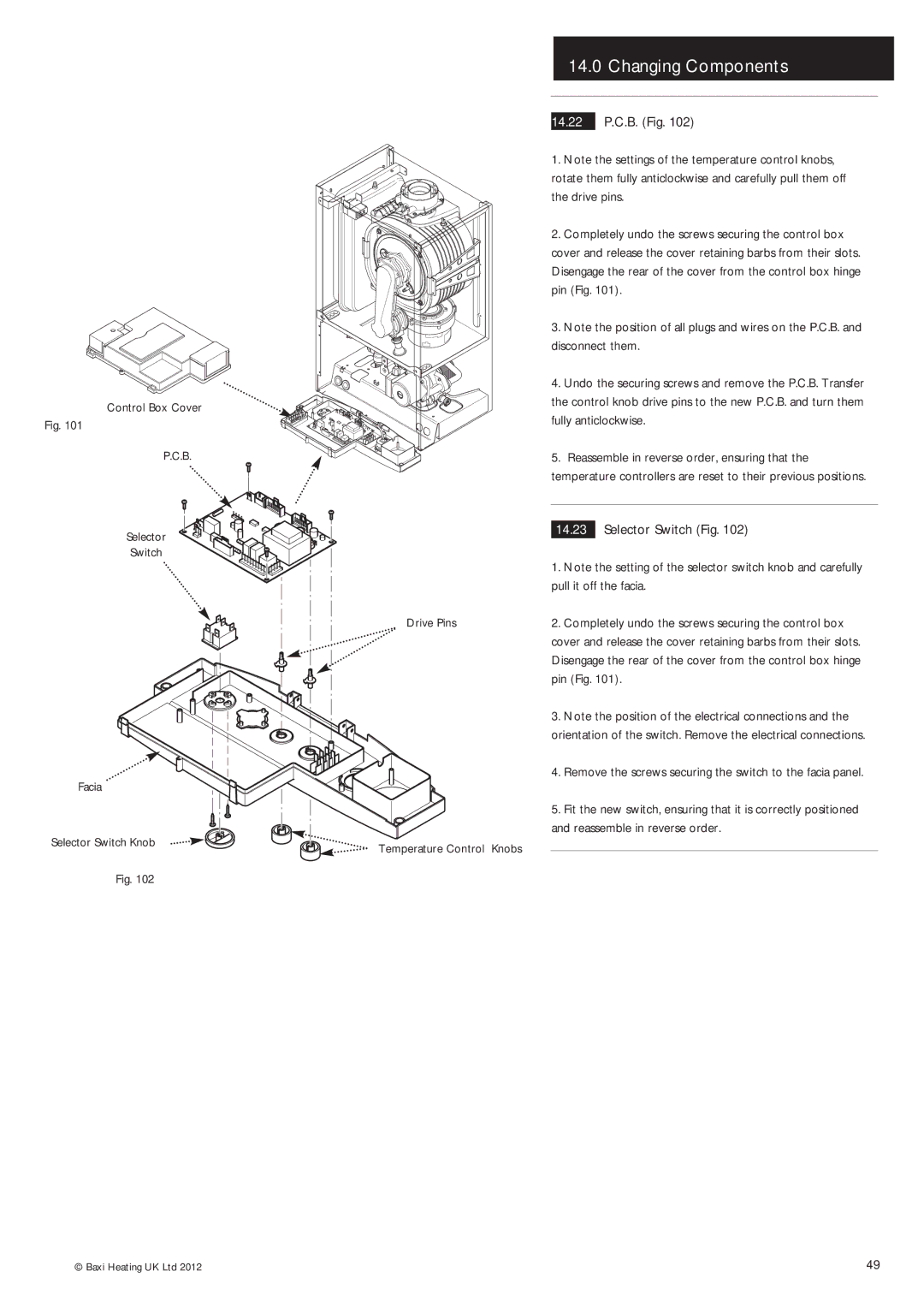

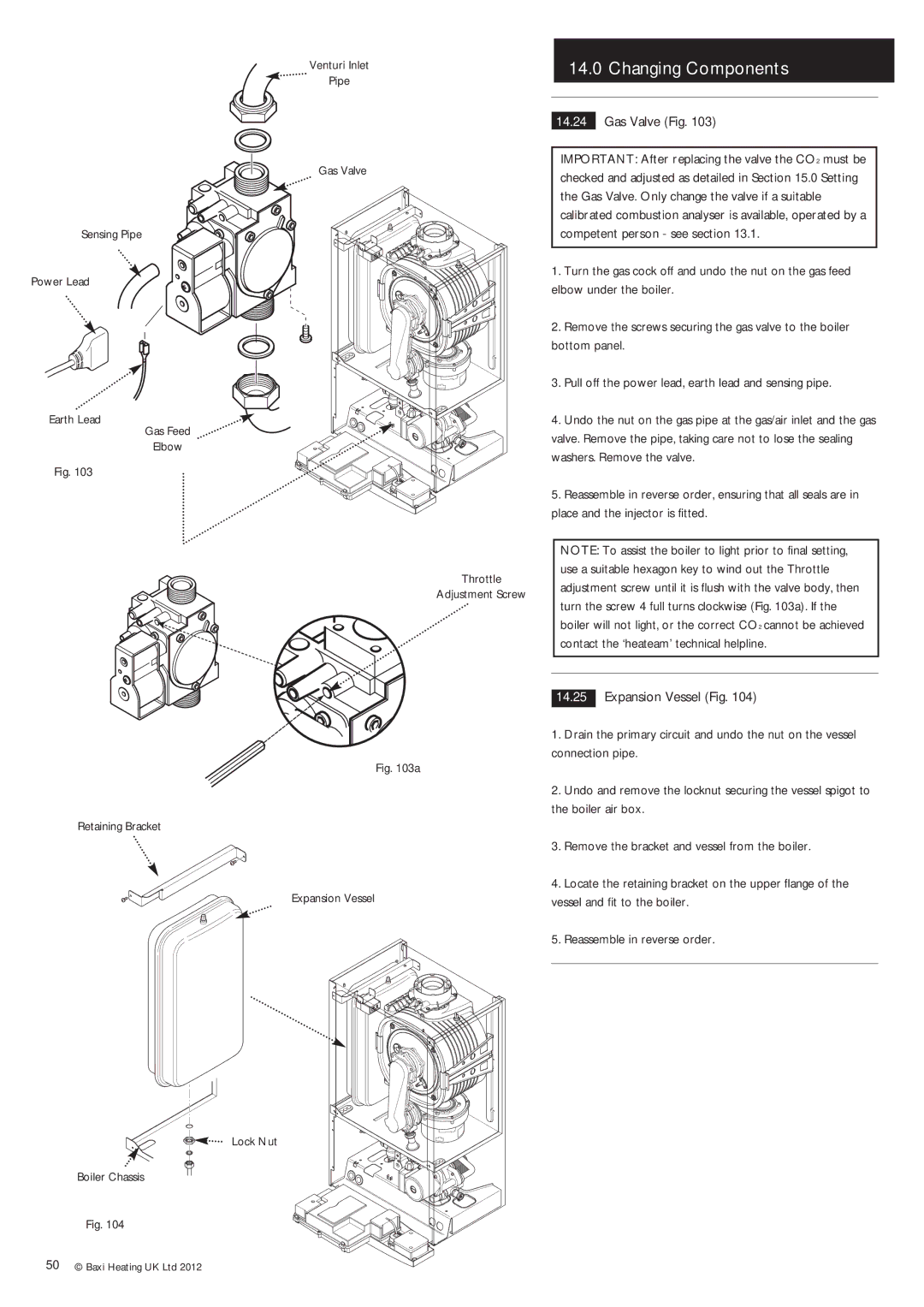

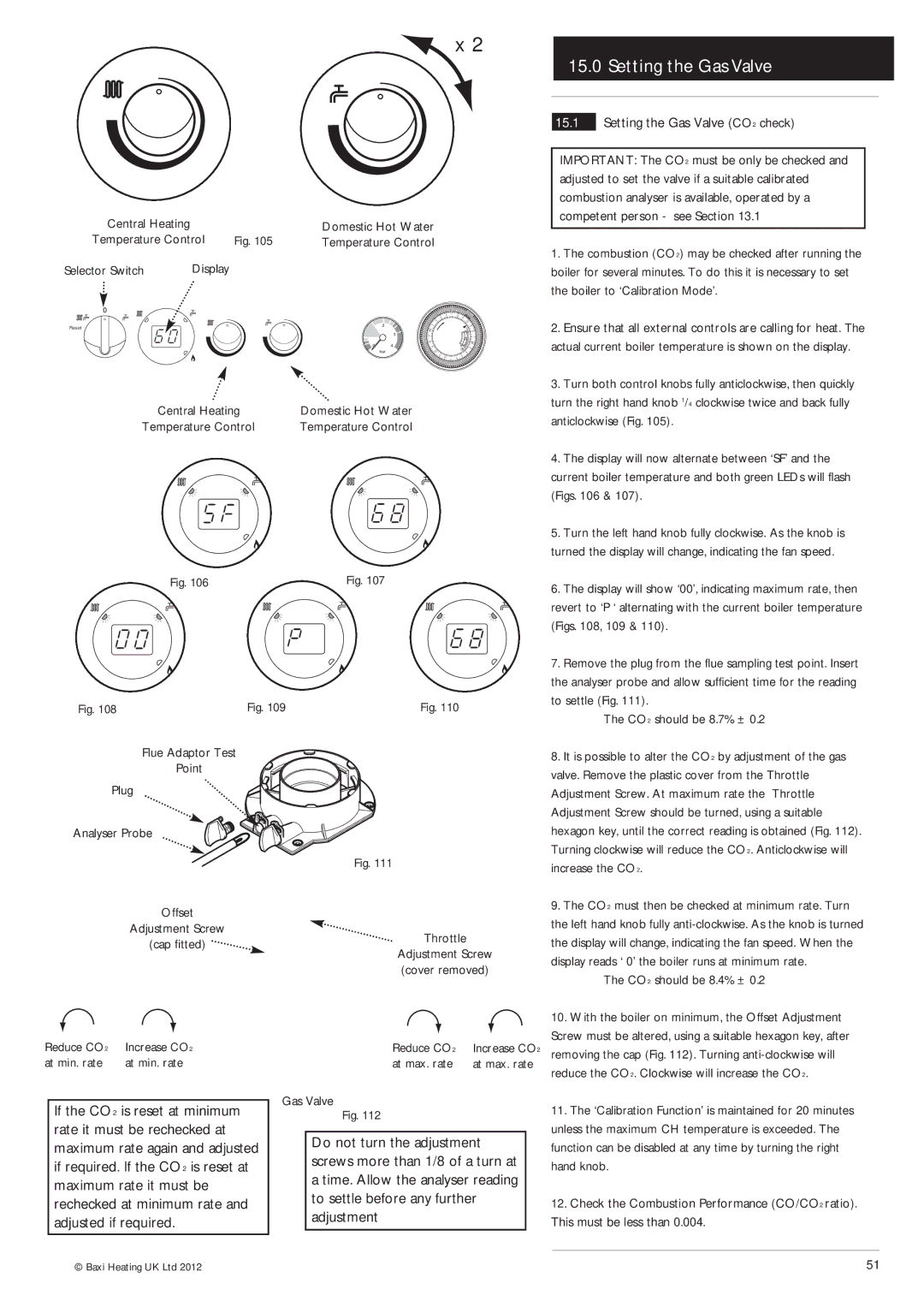

11.0Commissioning

11.2Check the Operational (Working) Gas Inlet Pressure

1.Ensure that all controls are calling for heat, and the selector

switch is in the central heating and hot water position (![]()

![]()

![]() ). The current boiler temperature is shown on the display.

). The current boiler temperature is shown on the display.

2.It is necessary to set the boiler to ‘Calibration Mode’.

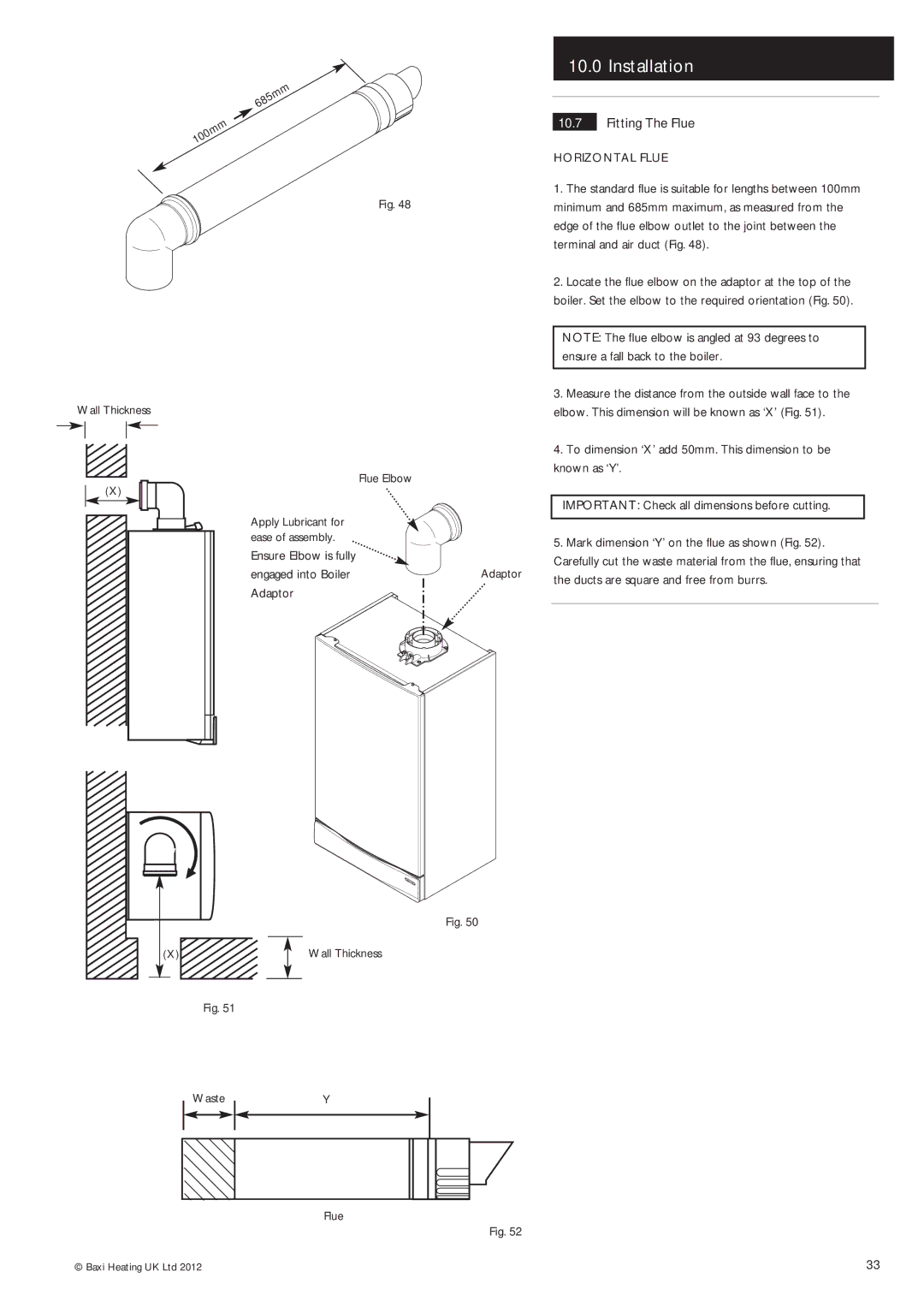

3.Turn both temperature control knobs fully anticlockwise, then quickly turn the DHW temperature knob 1/4 clockwise twice and back fully anticlockwise (Fig. 66).

4.The display will now alternate between ‘SF’ and the current boiler temperature and both green LEDs will flash (Figs. 67 & 68).

5.Turn CH temperature control knob fully clockwise. As the knob is turned the display will change from ‘0’ to ‘00’ (Fig. 69) indicating maximum rate, then revert to ‘P’ alternating with the current boiler temperature (Figs 70 & 71).

6.With the boiler operating in the maximum rate condition check that the operational (working) gas pressure at the inlet gas pressure test point (Fig. 66a) is in accordance with B.S.

6798 & B.S. 6891.

7.Ensure that this inlet pressure can be obtained with all other gas appliances in the property working.

Measure the Gas Rate

8.With any other appliances & pilot lights turned OFF the gas rate can be measured. It should be between:-

24 model | 2.6m3/h |

28 model | 3.1m3/h |

33 model | 3.6 m3/h |

9.The ‘Calibration Function’ is active for 20 minutes unless the maximum CH temperature is exceeded.

10.The function can be disabled at any time by turning the DHW temperature knob.

11.Carefully read and complete all sections of the Benchmark Commissioning Checklist at the rear of this publication that are relevant to the boiler and installation. These details will be required in the event of any warranty work. The publication must be handed to the user for safe keeping and each subsequent regular service visit recorded.

12.For IE, it is necessary to complete a “Declaration of Conformity” to indicate compliance with I.S. 813. An example of this is given in I.S. 813 “Domestic Gas Installations”. This is in addition to the Benchmark Commissioning Checklist.

© Baxi Heating UK Ltd 2012 | 37 |