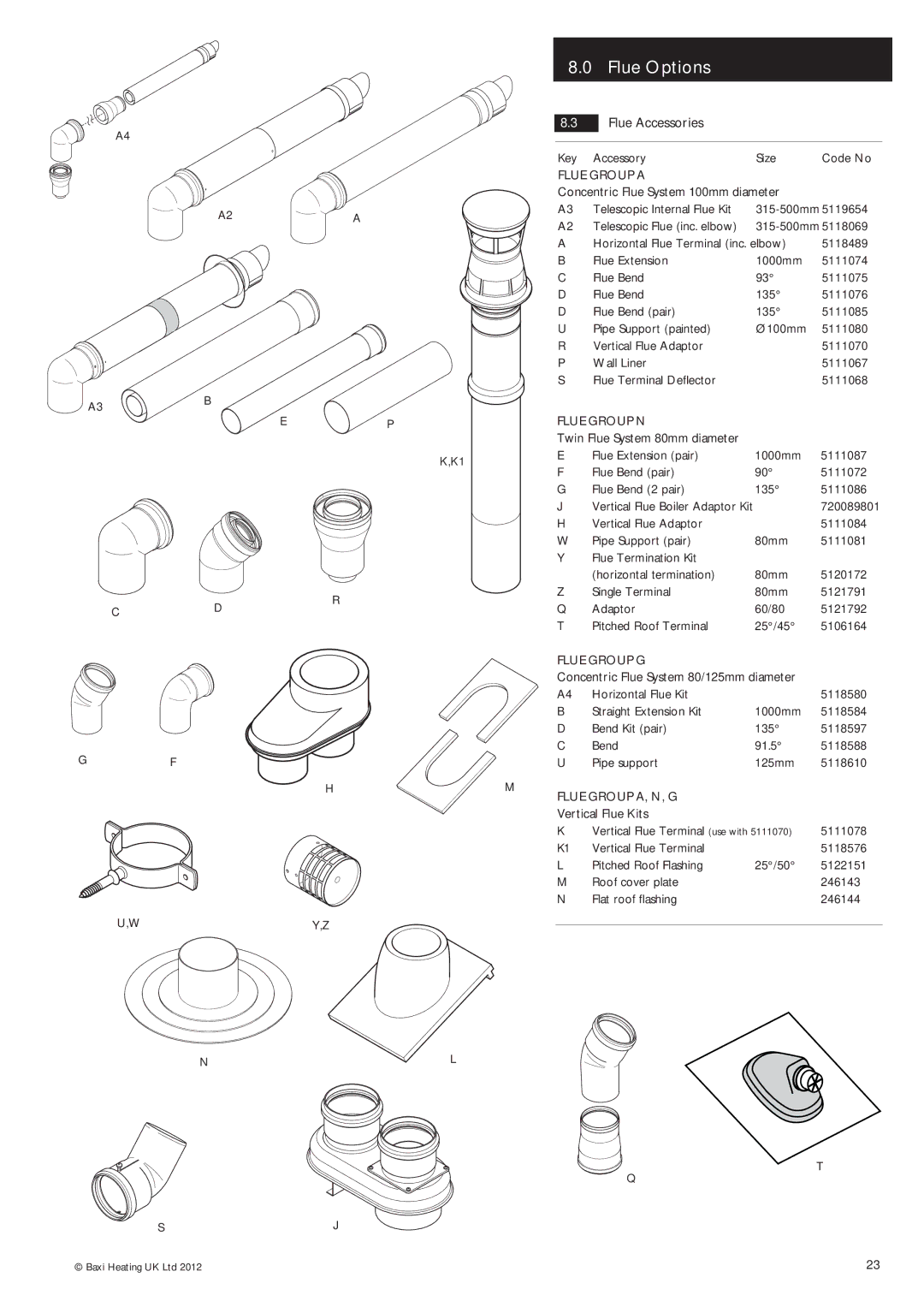

O Ring ![]()

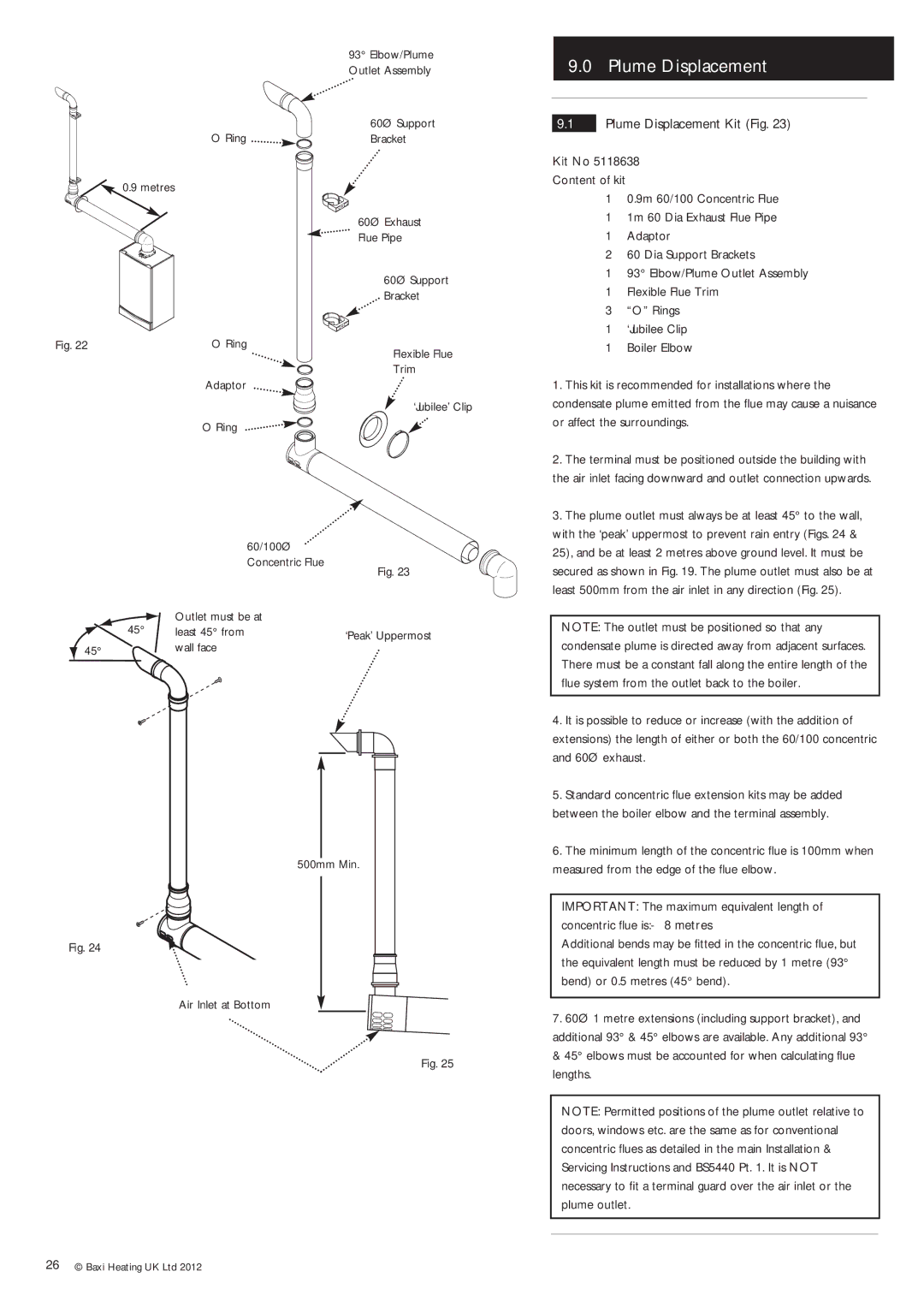

![]() 0.9 metres

0.9 metres

Fig. 22 | O Ring |

Adaptor

O Ring

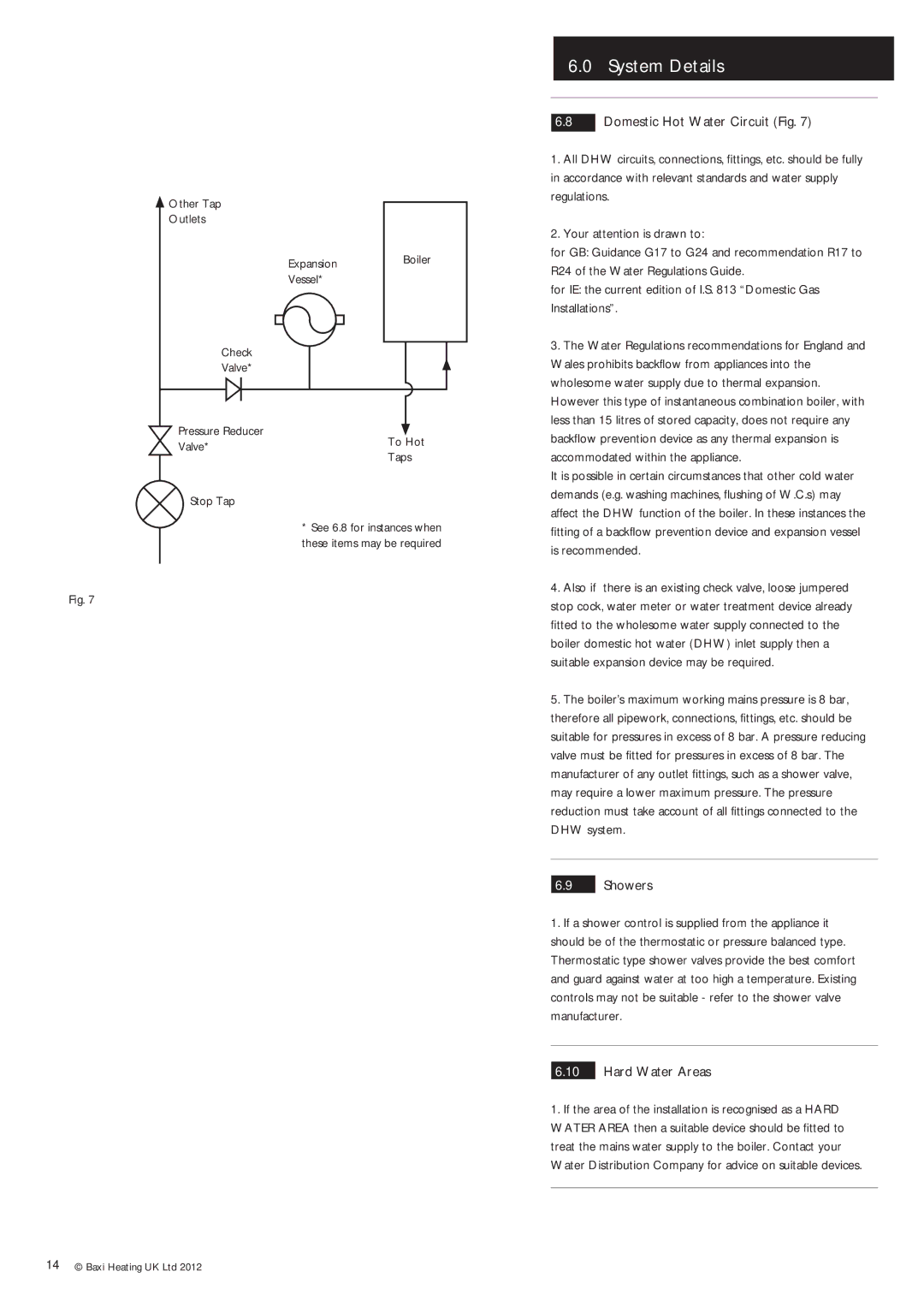

60/100Ø ![]() Concentric Flue

Concentric Flue

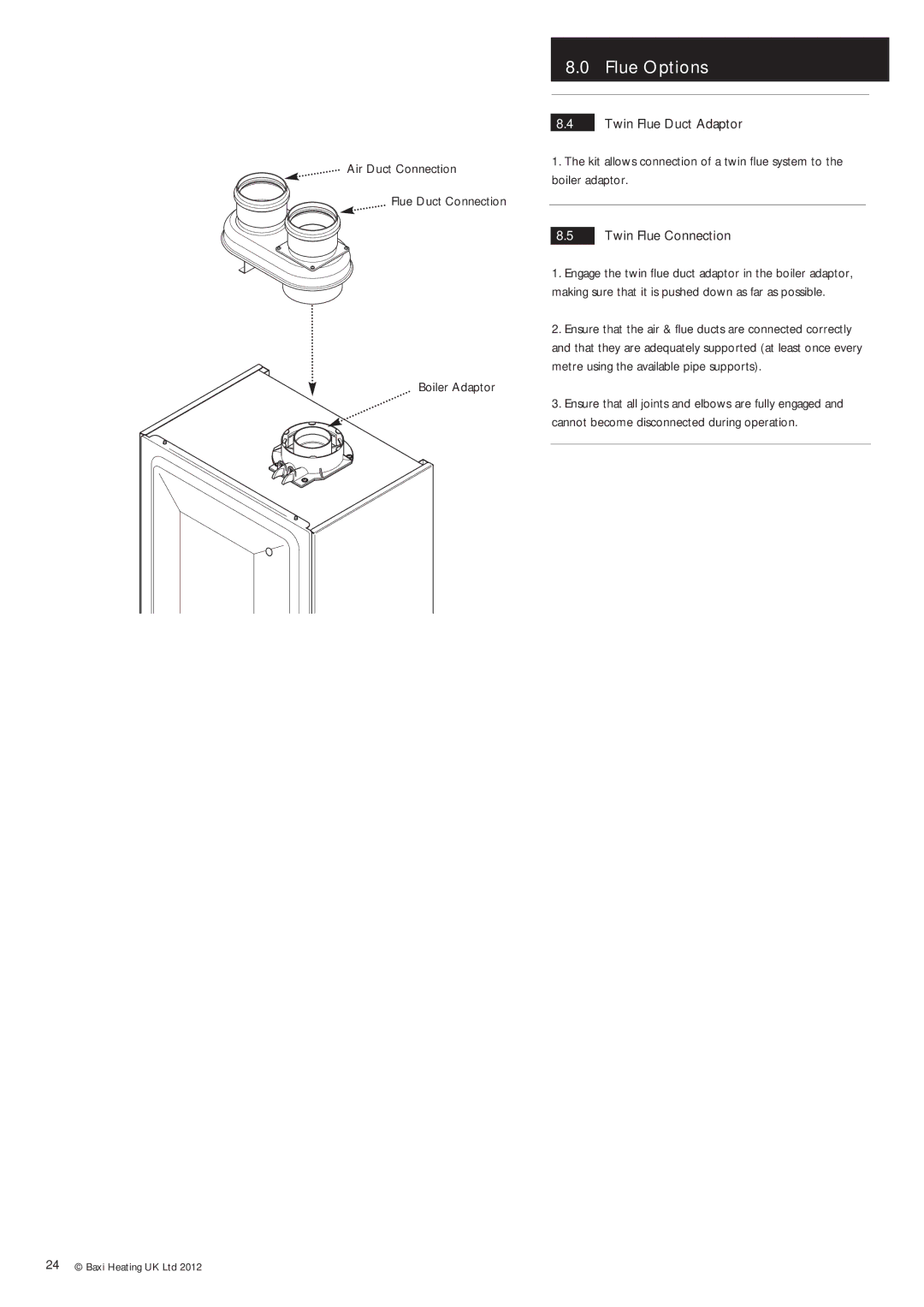

45° | Outlet must be at |

least 45° from | |

45° | wall face |

93° Elbow/Plume Outlet Assembly

60Ø Support

Bracket

60Ø Exhaust

Flue Pipe

60Ø Support

![]() Bracket

Bracket

Flexible Flue

Trim

‘Jubilee’ Clip

Fig. 23

‘Peak’ Uppermost

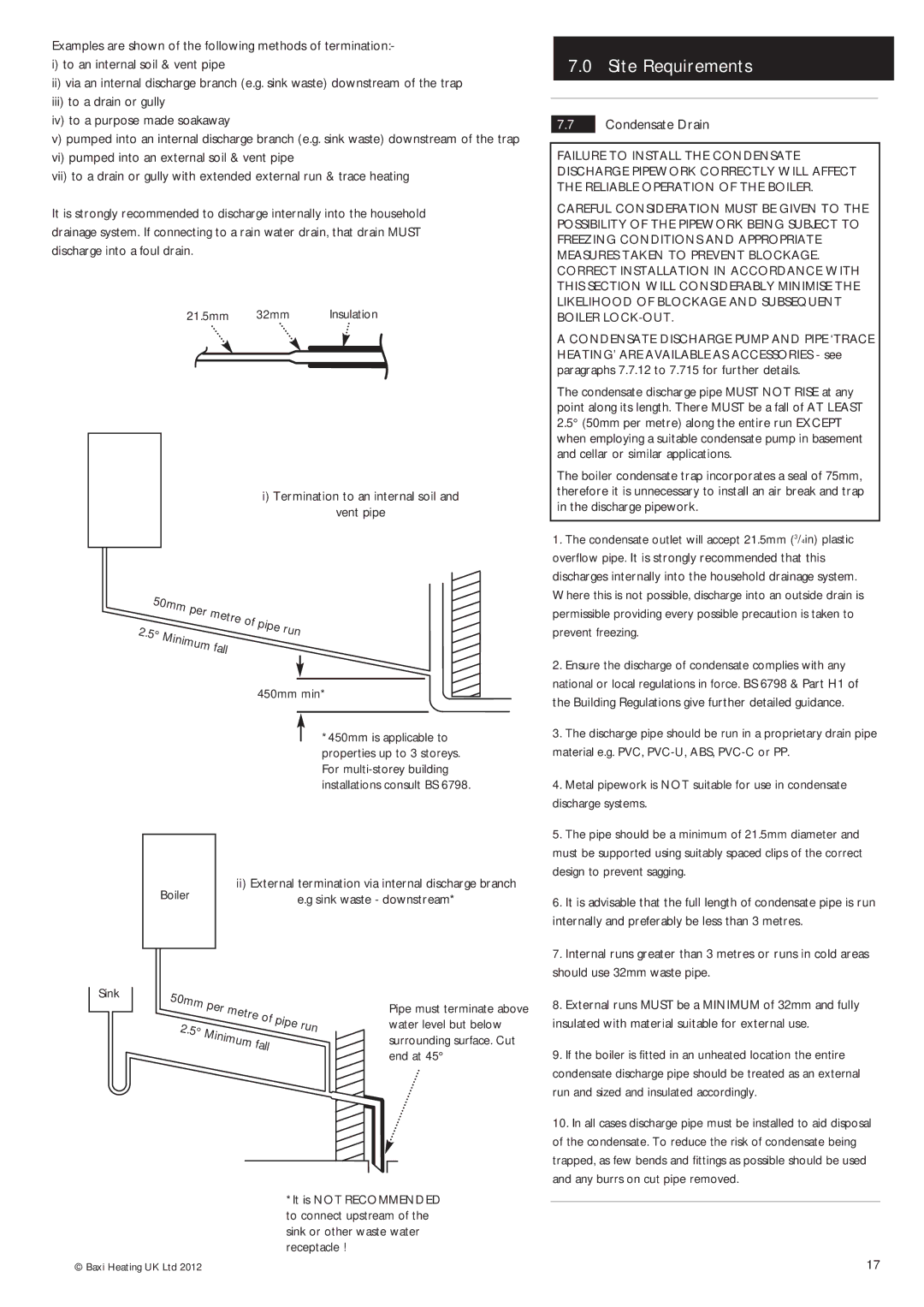

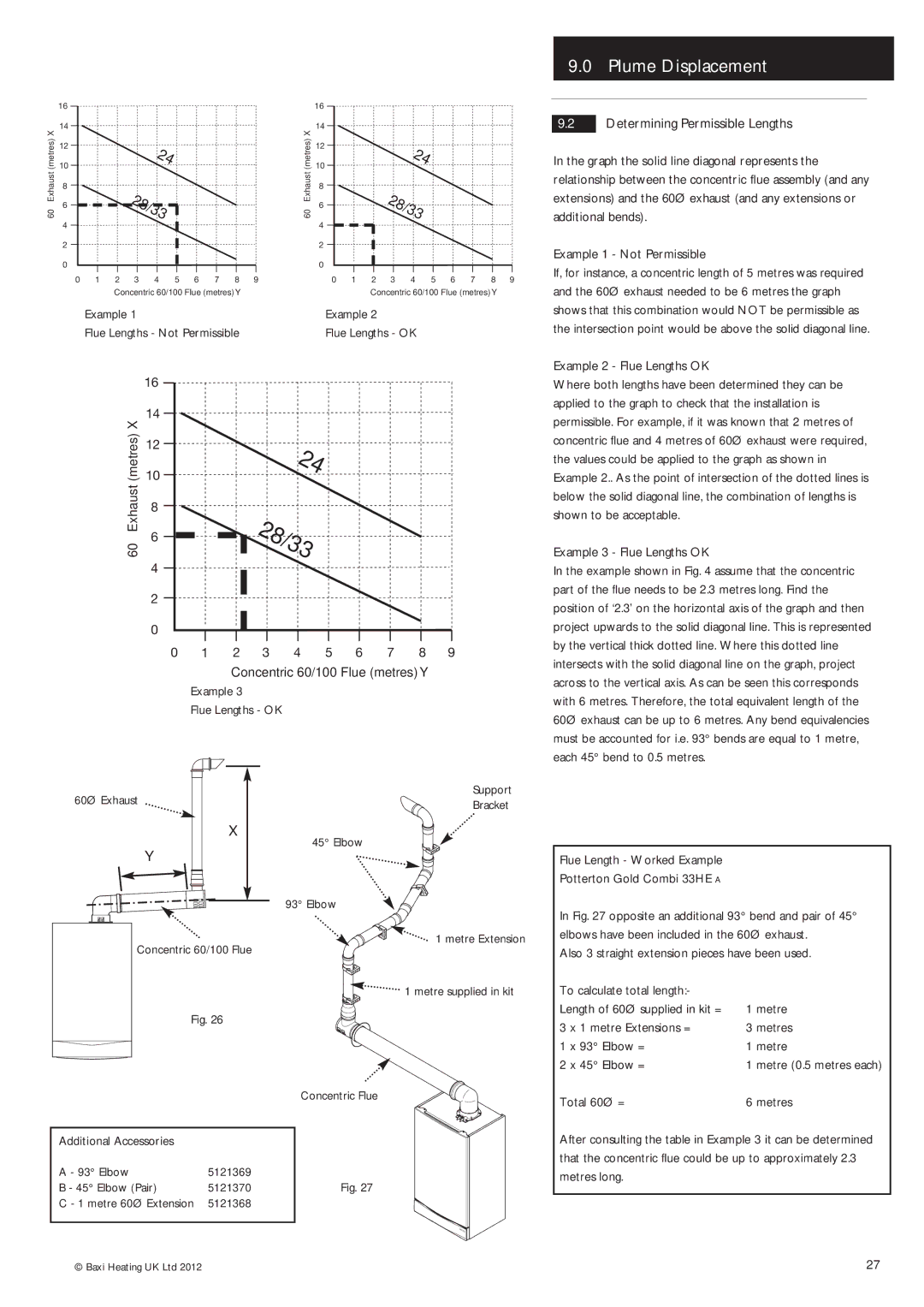

9.0 Plume Displacement

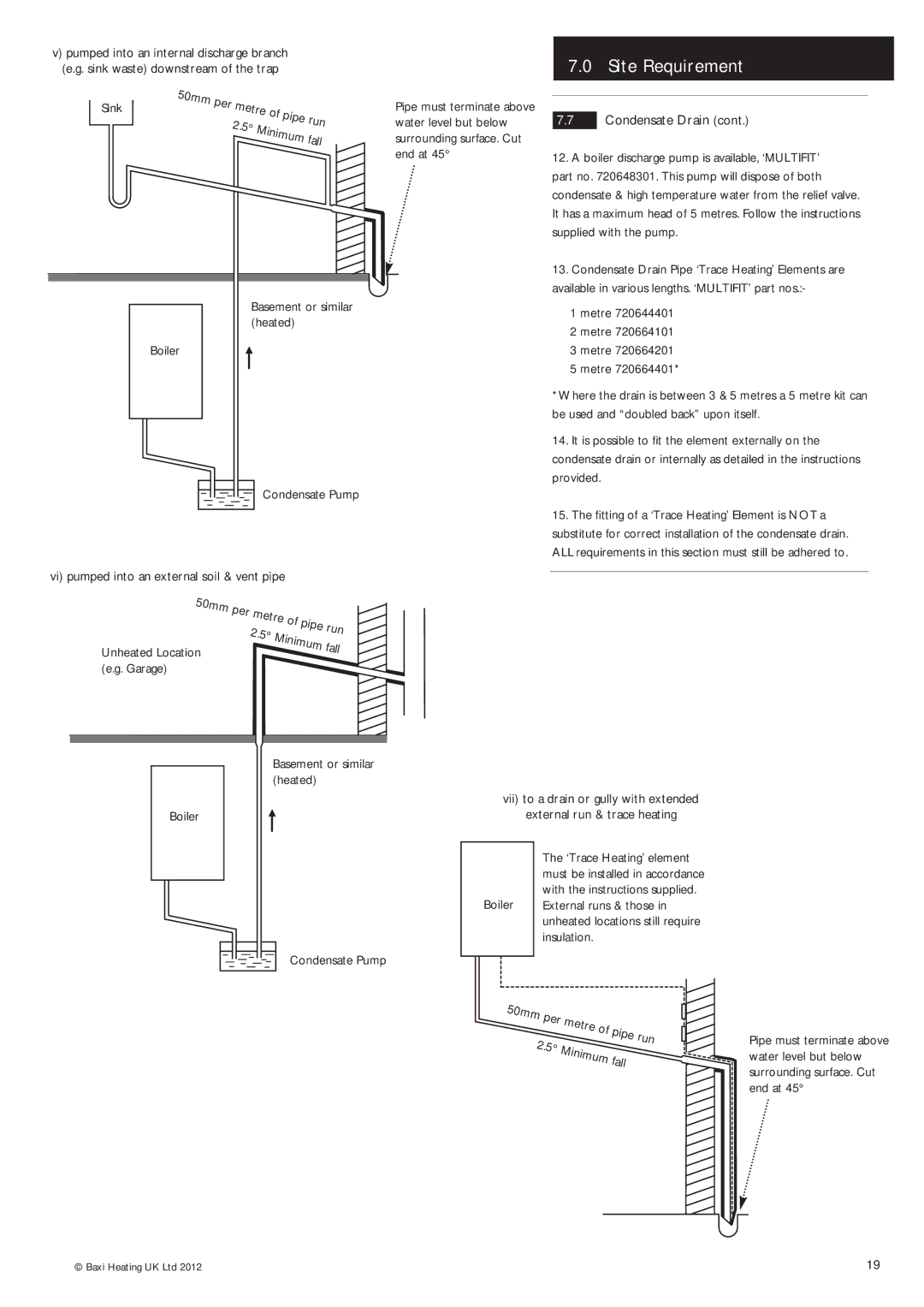

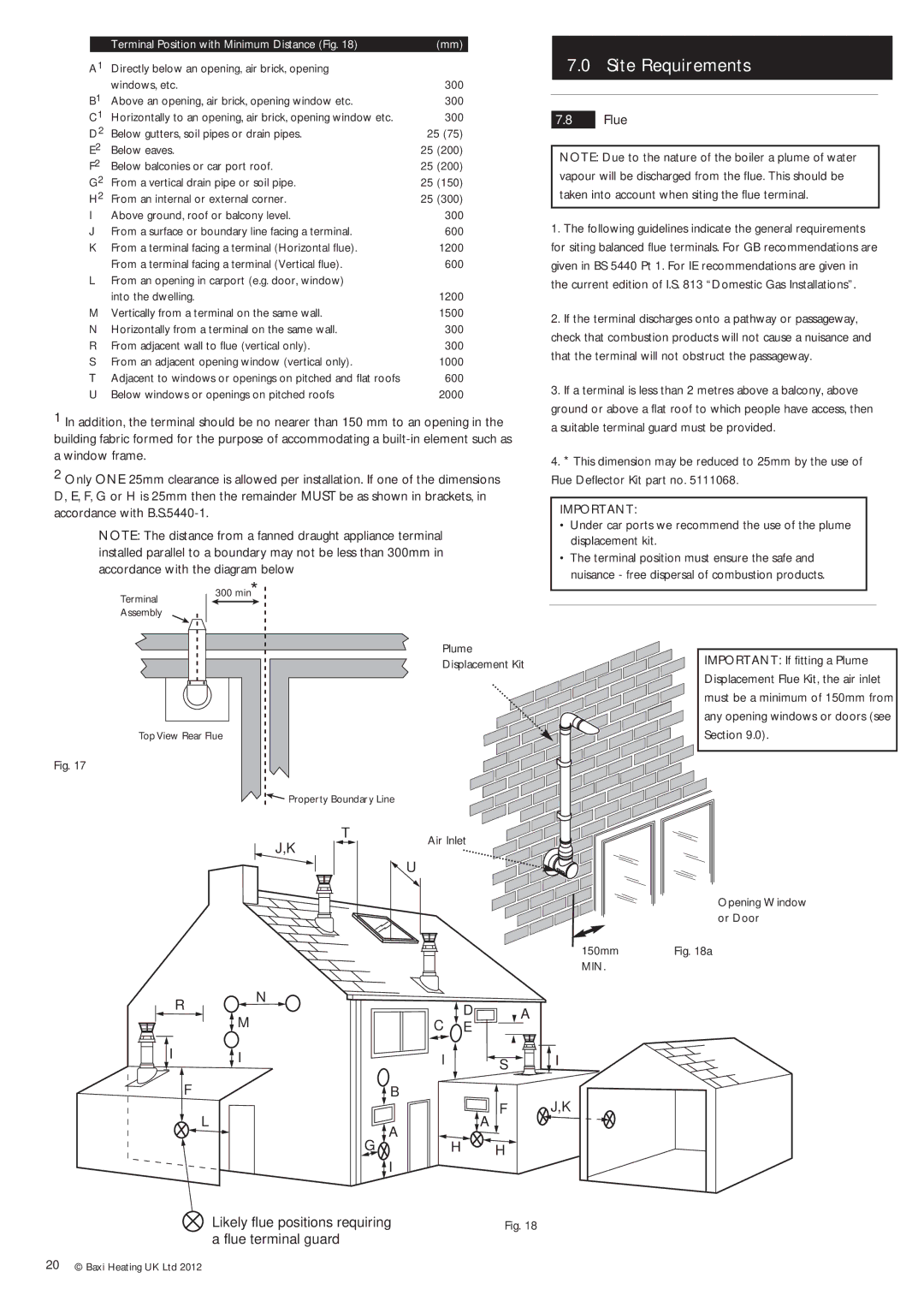

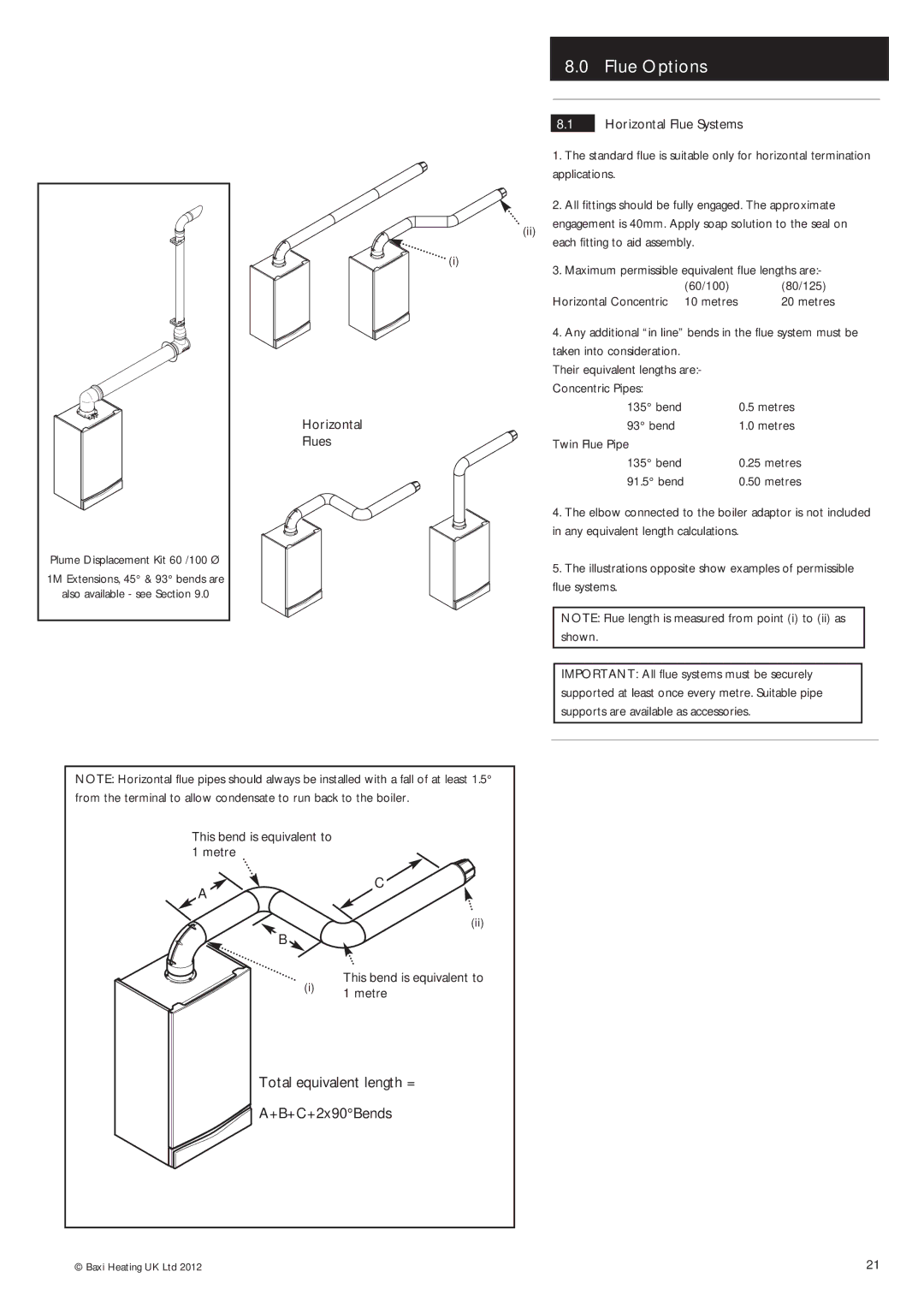

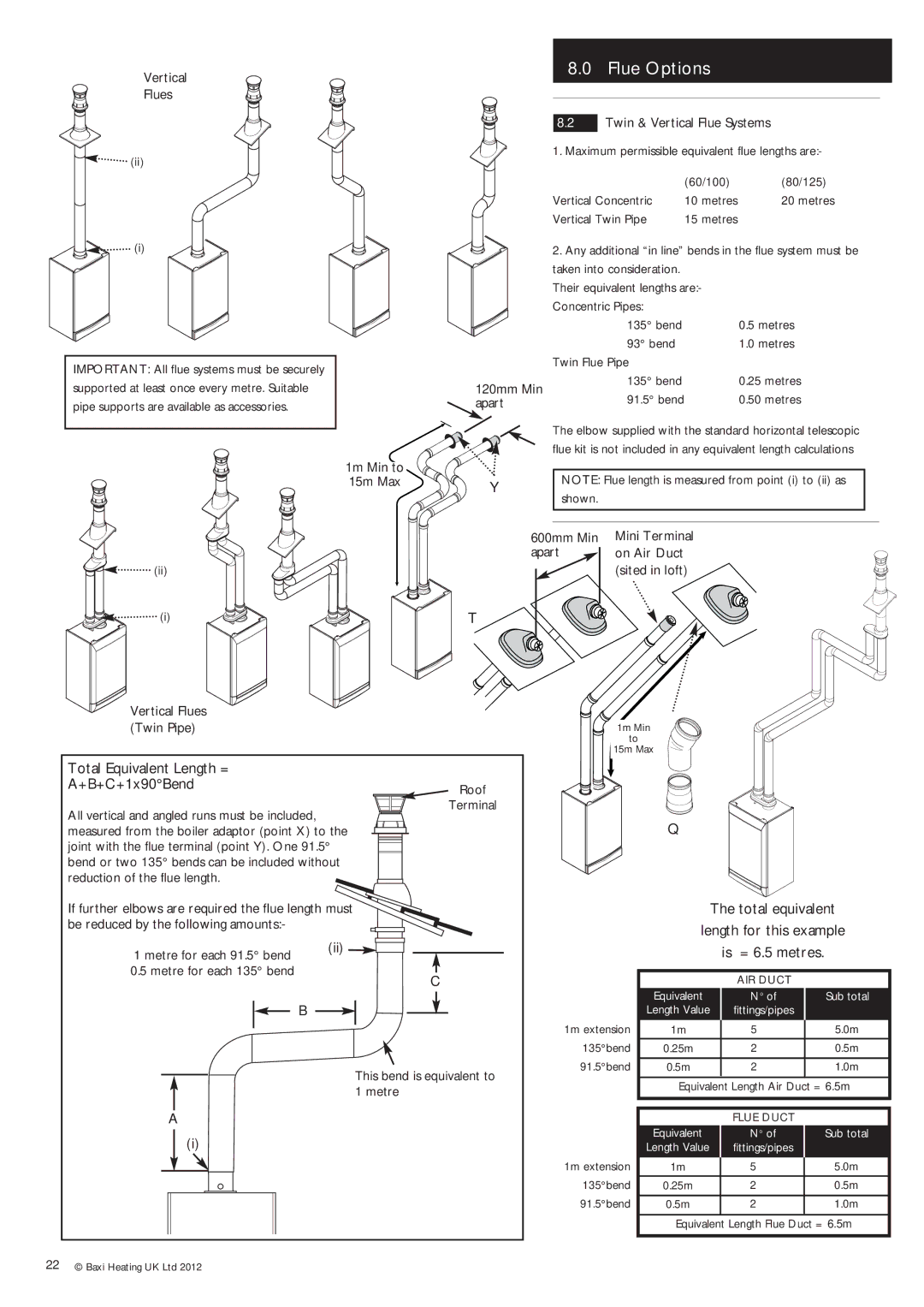

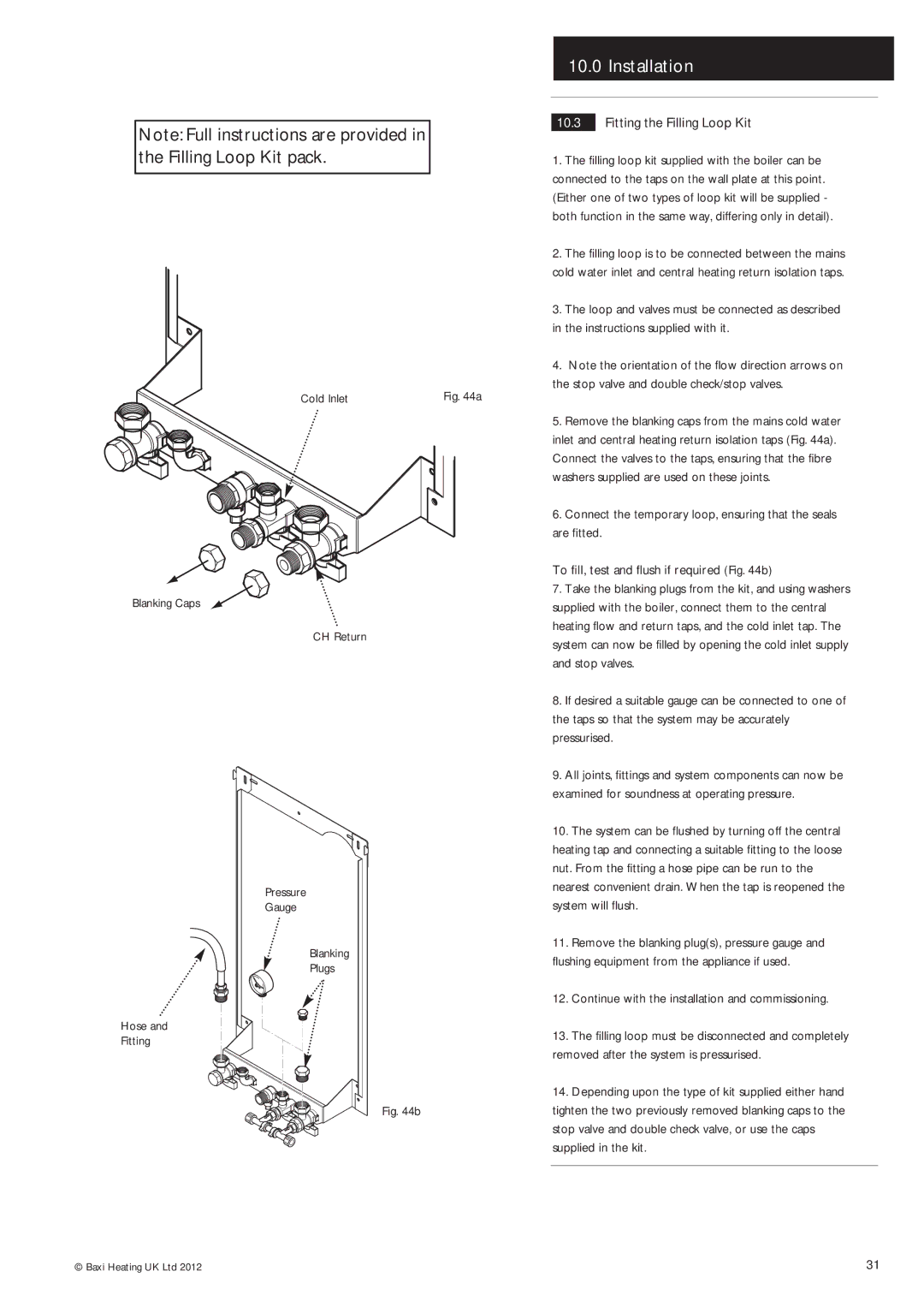

9.1 Plume Displacement Kit (Fig. 23)

Kit No 5118638

Content of kit

10.9m 60/100 Concentric Flue

11m 60 Dia Exhaust Flue Pipe

1Adaptor

260 Dia Support Brackets

193° Elbow/Plume Outlet Assembly

1Flexible Flue Trim

3“O” Rings

1‘Jubilee Clip

1Boiler Elbow

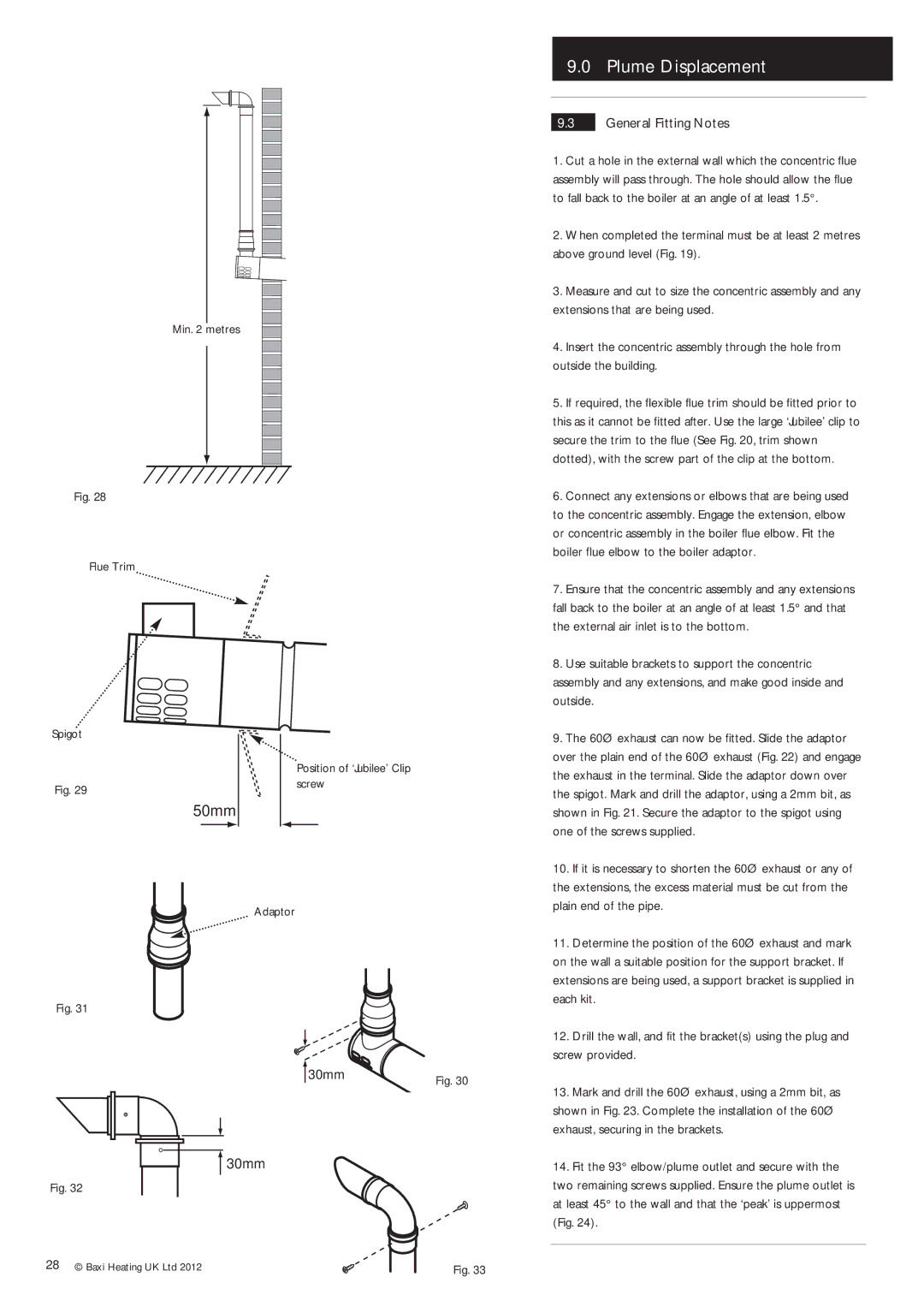

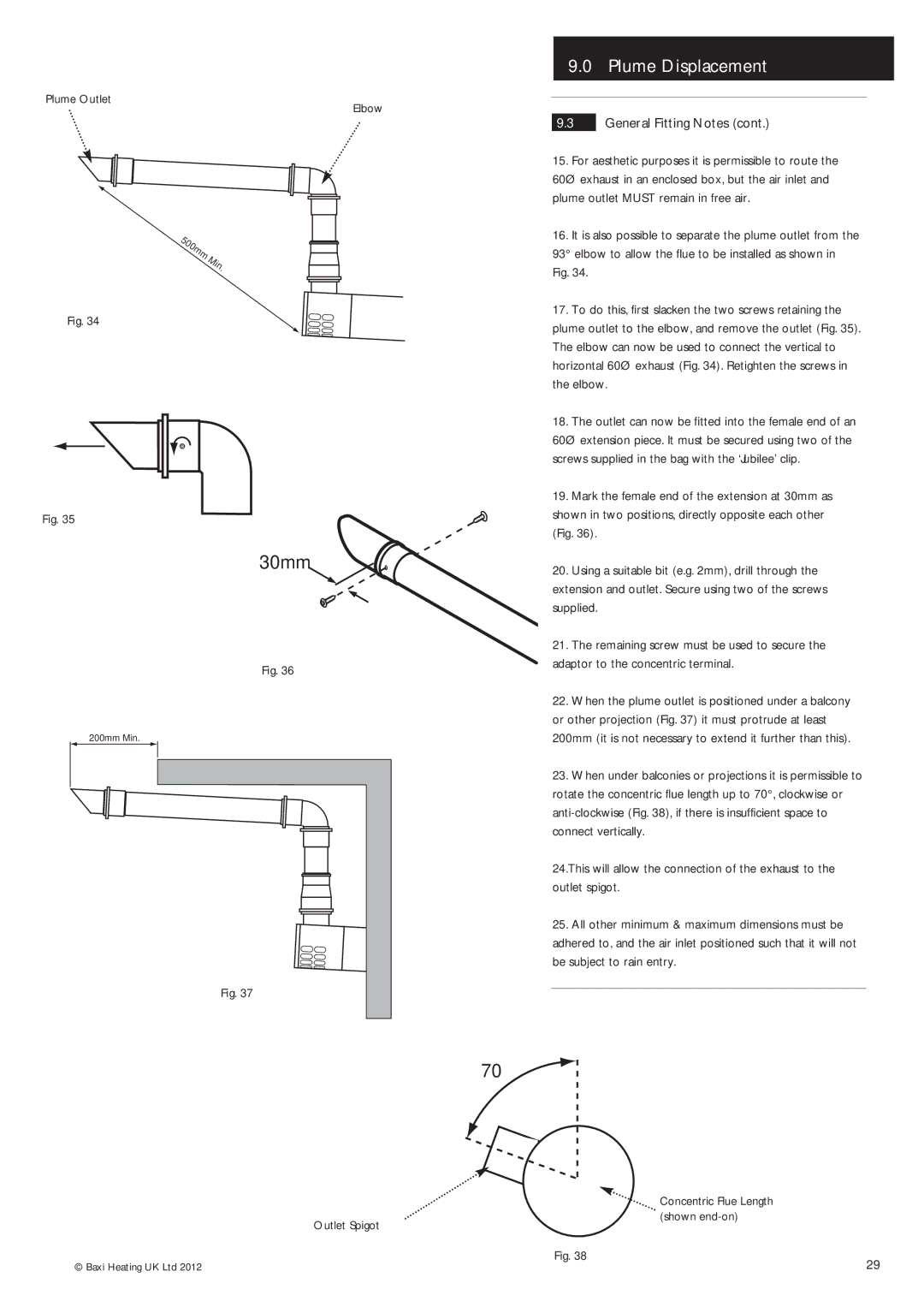

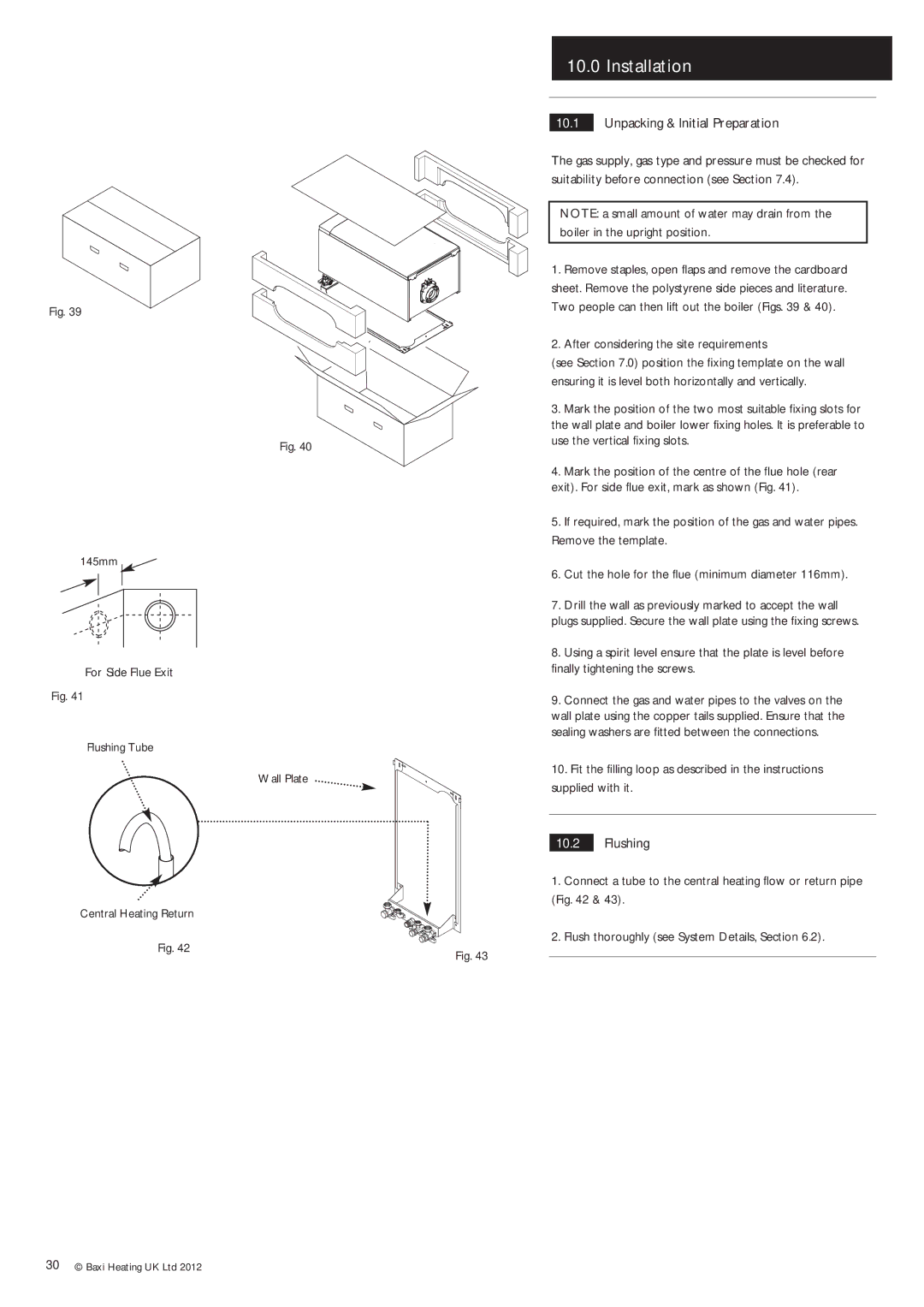

1.This kit is recommended for installations where the condensate plume emitted from the flue may cause a nuisance or affect the surroundings.

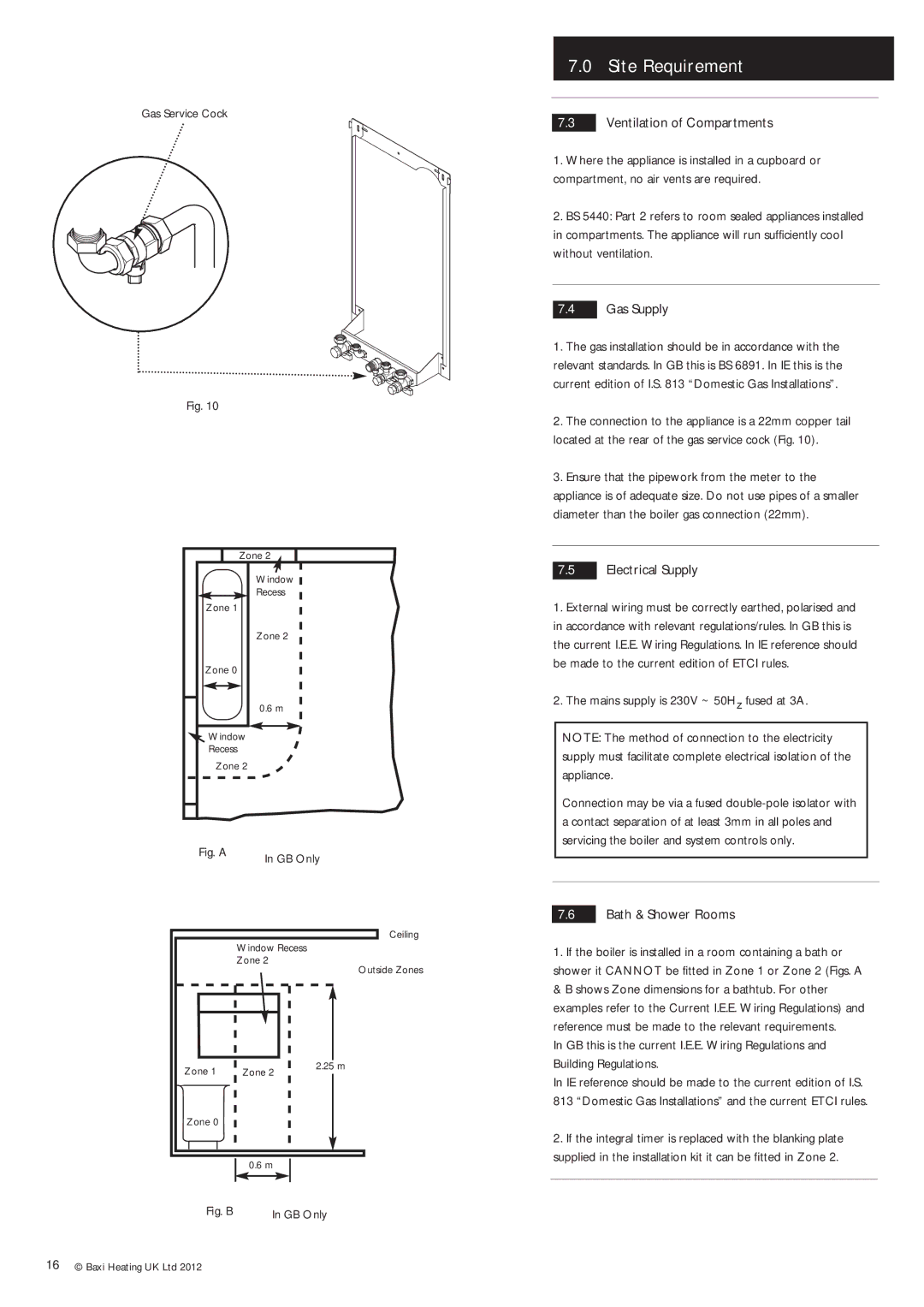

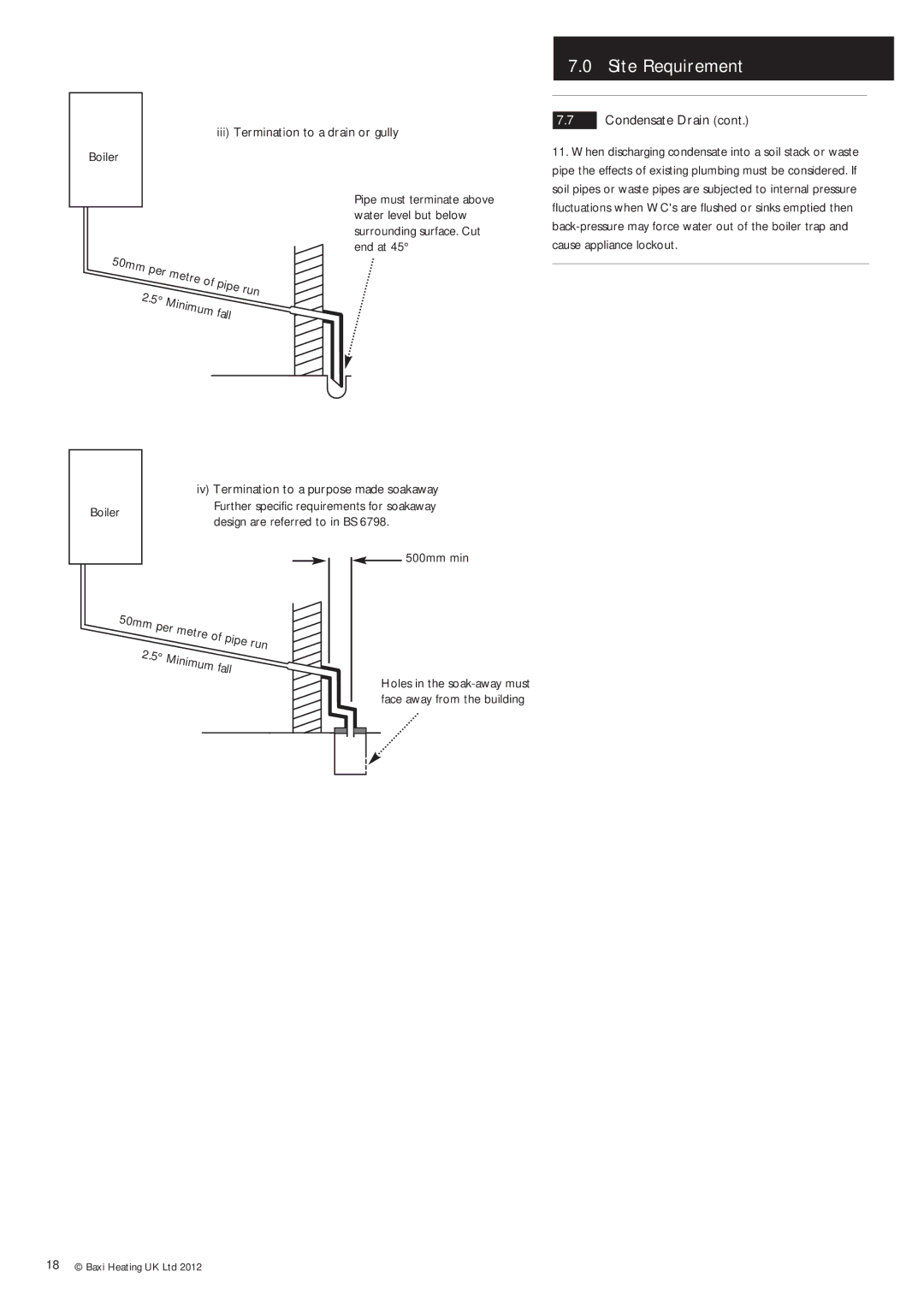

2.The terminal must be positioned outside the building with the air inlet facing downward and outlet connection upwards.

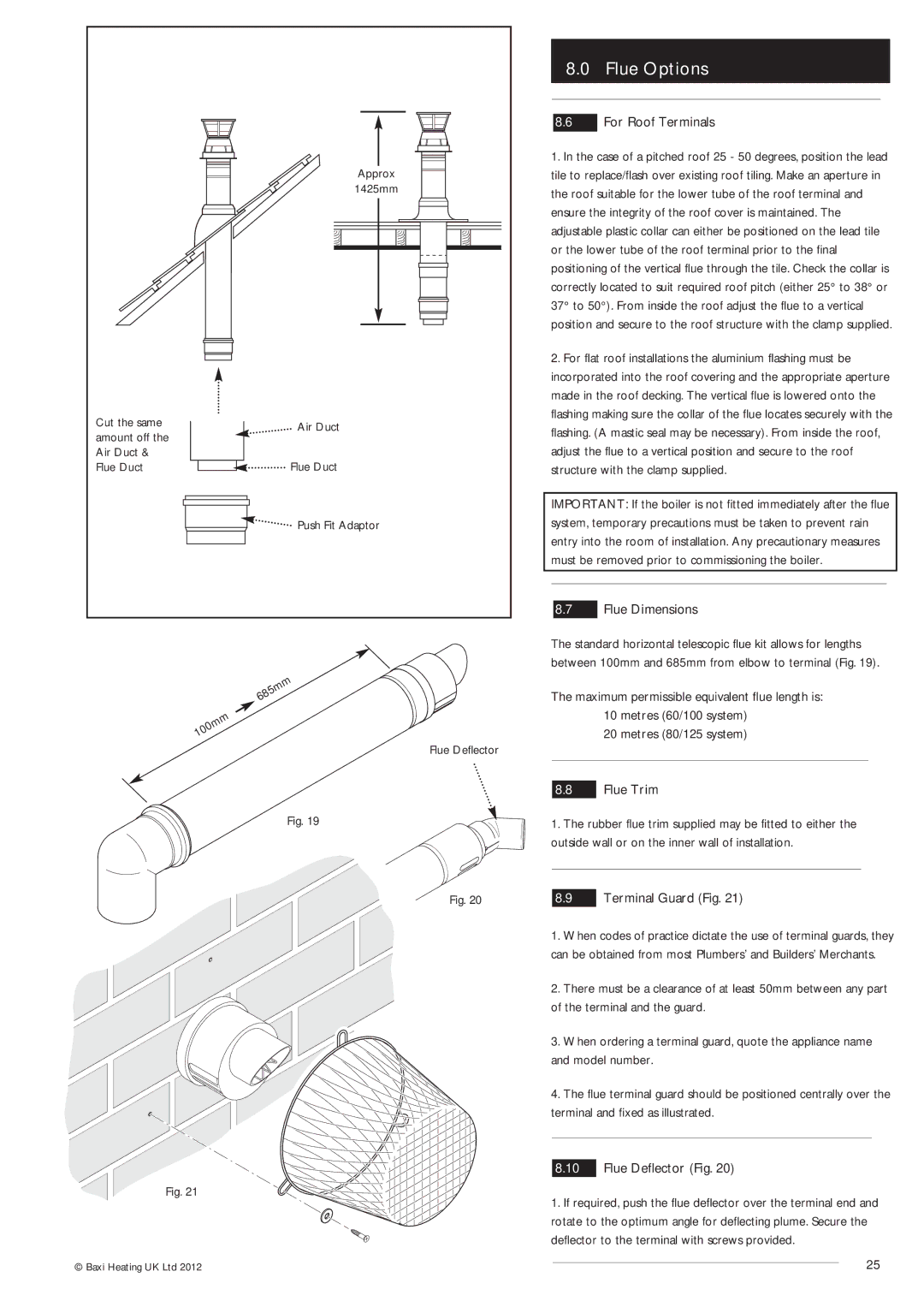

3.The plume outlet must always be at least 45° to the wall, with the ‘peak’ uppermost to prevent rain entry (Figs. 24 & 25), and be at least 2 metres above ground level. It must be secured as shown in Fig. 19. The plume outlet must also be at least 500mm from the air inlet in any direction (Fig. 25).

NOTE: The outlet must be positioned so that any condensate plume is directed away from adjacent surfaces. There must be a constant fall along the entire length of the flue system from the outlet back to the boiler.

500mm Min.

Fig. 24

Air Inlet at Bottom

Fig. 25

4.It is possible to reduce or increase (with the addition of extensions) the length of either or both the 60/100 concentric and 60Ø exhaust.

5.Standard concentric flue extension kits may be added between the boiler elbow and the terminal assembly.

6.The minimum length of the concentric flue is 100mm when measured from the edge of the flue elbow.

IMPORTANT: The maximum equivalent length of

concentric flue is:- 8 metres

Additional bends may be fitted in the concentric flue, but the equivalent length must be reduced by 1 metre (93° bend) or 0.5 metres (45° bend).

7.60Ø 1 metre extensions (including support bracket), and additional 93° & 45° elbows are available. Any additional 93° & 45° elbows must be accounted for when calculating flue lengths.

NOTE: Permitted positions of the plume outlet relative to doors, windows etc. are the same as for conventional concentric flues as detailed in the main Installation & Servicing Instructions and BS5440 Pt. 1. It is NOT necessary to fit a terminal guard over the air inlet or the plume outlet.

26© Baxi Heating UK Ltd 2012