|

|

|

|

|

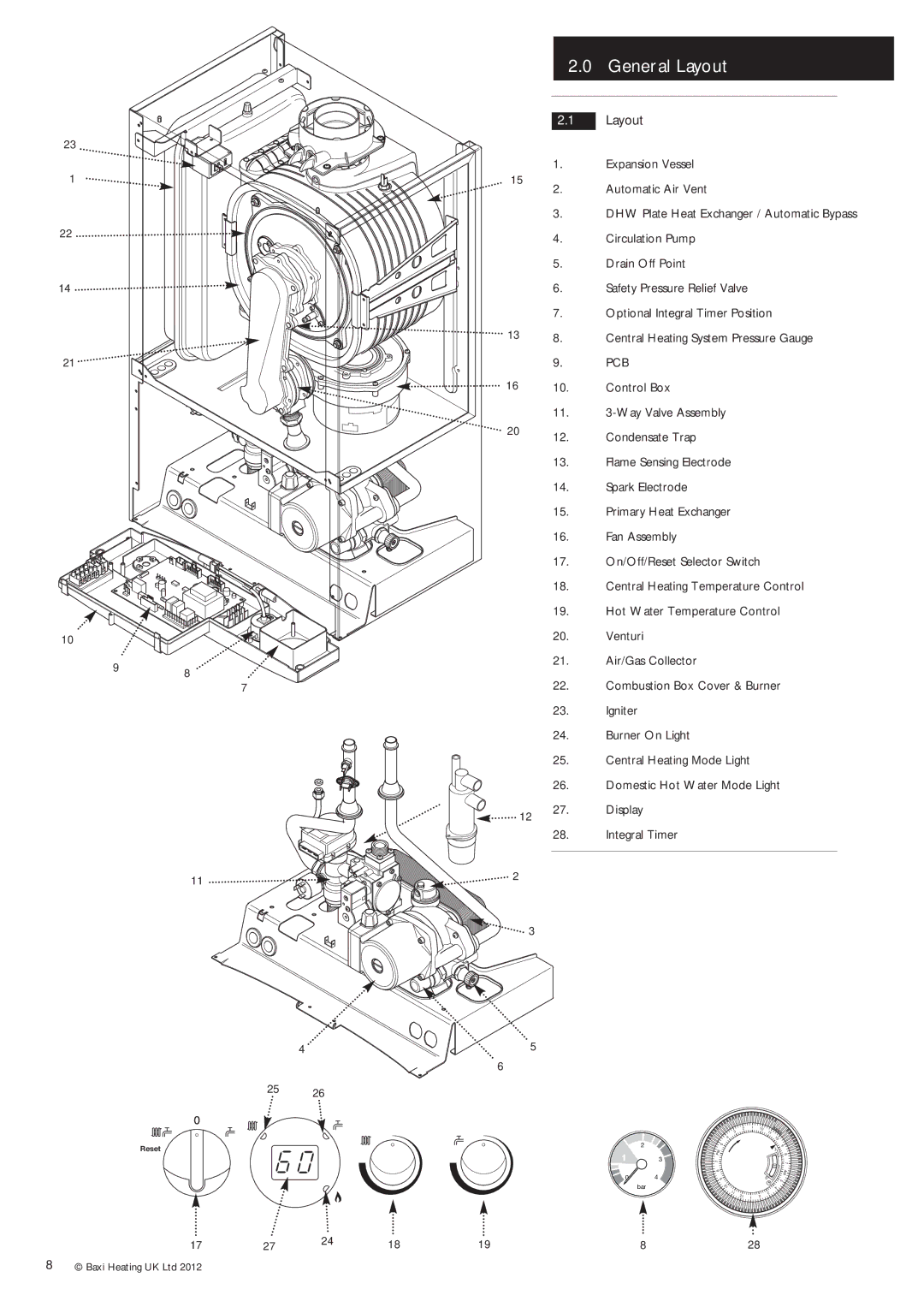

| 2.0 | General Layout |

|

|

| ||

|

|

|

|

|

| 2.1 | Layout |

|

|

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

| 1. | Expansion Vessel |

|

|

|

| |

|

|

|

| 15 | 2. | Automatic Air Vent |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| 3. | DHW Plate Heat Exchanger / Automatic Bypass | |||||

22 |

|

|

|

|

| 4. | Circulation Pump |

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| 5. | Drain Off Point |

|

|

|

| |

14 |

|

|

|

|

| 6. | Safety Pressure Relief Valve |

|

|

| ||

|

|

|

|

|

| 7. | Optional Integral Timer Position |

| ||||

|

|

|

|

| 13 | 8. | Central Heating System Pressure Gauge | |||||

21 |

|

|

|

|

| 9. | PCB |

|

|

|

|

|

|

|

|

|

| 16 | 10. | Control Box |

|

|

|

| |

|

|

|

|

|

| 11. |

|

|

| |||

|

|

|

|

| 20 | 12. | Condensate Trap |

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

| 13. | Flame Sensing Electrode |

|

|

| ||

|

|

|

|

|

| 14. | Spark Electrode |

|

|

|

| |

|

|

|

|

|

| 15. | Primary Heat Exchanger |

|

|

| ||

|

|

|

|

|

| 16. | Fan Assembly |

|

|

|

| |

|

|

|

|

|

| 17. | On/Off/Reset Selector Switch |

| ||||

|

|

|

|

|

| 18. | Central Heating Temperature Control | |||||

|

|

|

|

|

| 19. | Hot Water Temperature Control |

| ||||

10 |

|

|

|

|

| 20. | Venturi |

|

|

|

|

|

9 | 8 |

|

|

|

| 21. | Air/Gas Collector |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| 22. | Combustion Box Cover & Burner | ||||||

|

| 7 |

|

|

| |||||||

|

|

|

|

|

| 23. | Igniter |

|

|

|

|

|

|

|

|

|

|

| 24. | Burner On Light |

|

|

|

| |

|

|

|

|

|

| 25. | Central Heating Mode Light |

|

| |||

|

|

|

|

|

| 26. | Domestic Hot Water Mode Light |

| ||||

|

|

|

|

| 12 | 27. | Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| 28. | Integral Timer |

|

|

|

| |

| 11 |

|

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| 3 |

|

|

|

|

|

|

|

|

|

| 4 |

| 5 |

|

|

|

|

|

|

|

|

|

|

|

| 6 |

|

|

|

|

|

|

|

|

| 25 | 26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| 2 | 1 | 12 |

|

|

|

|

|

|

|

|

|

| 3 |

| 11 |

|

|

|

|

|

|

|

|

|

| 4 |

| 10 |

|

| Reset |

|

|

|

|

| 2 |

| 5 |

|

| 9 |

|

|

|

|

|

|

|

| PM |

|

|

| |

|

|

|

|

|

|

|

| 3 |

|

| 8 | |

|

|

|

|

|

|

|

| 7 |

|

| 7 | |

|

|

|

|

|

|

|

|

| 8 |

|

| AM |

|

|

|

|

|

|

| 0 | 4 | 9 |

| 0 | 5 |

|

|

|

|

|

|

| bar |

| 10 |

| 4 |

|

|

|

|

|

|

|

|

|

| 11 |

| 3 |

|

|

|

|

|

|

|

|

|

| 12 | 1 | 2 |

|

| 17 | 27 | 24 | 18 | 19 |

| 8 |

|

| 28 |

| |

8© Baxi Heating UK Ltd 2012