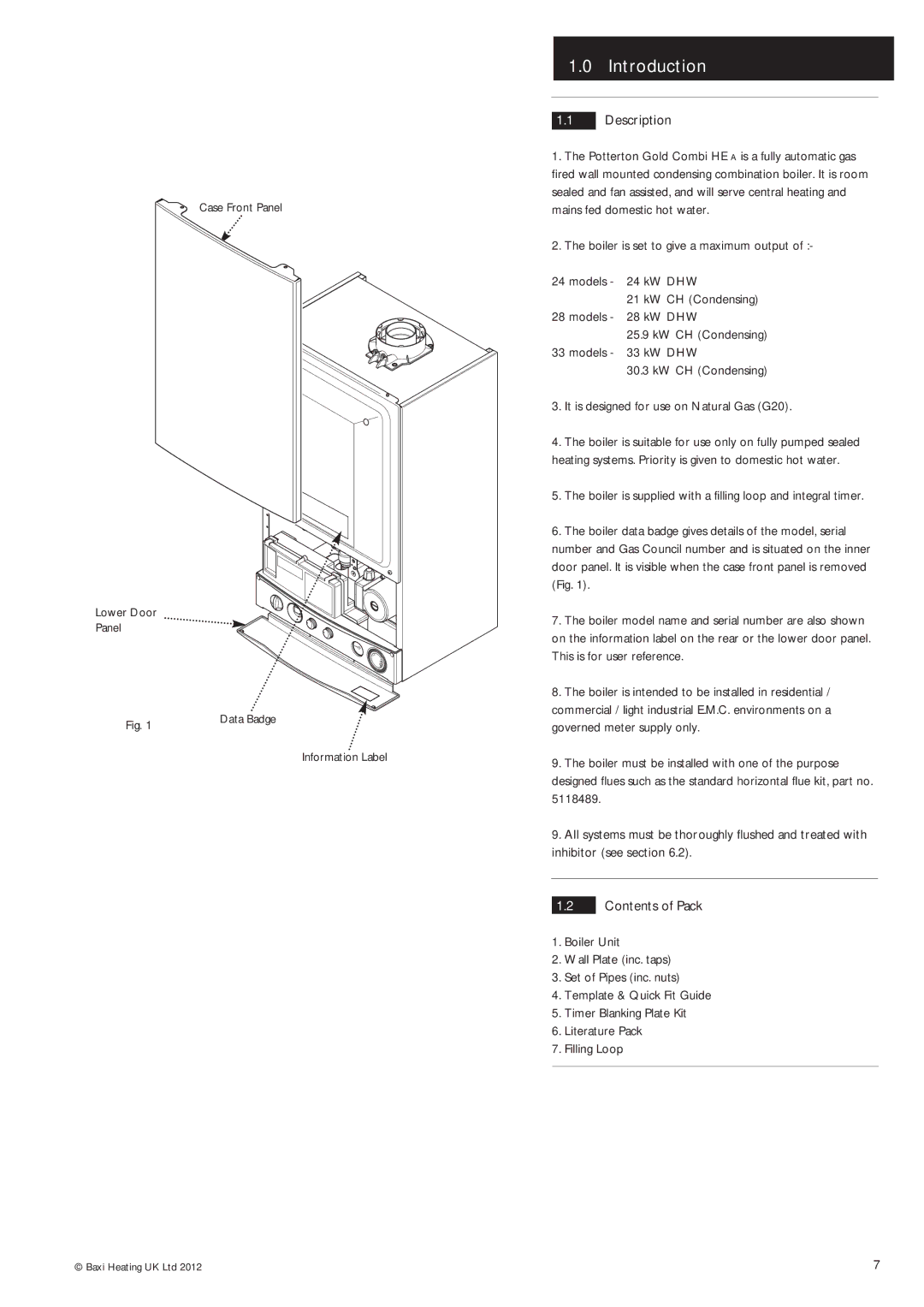

Case Front Panel

Lower Door

Panel

Fig. 1 | Data Badge |

|

Information Label

1.0Introduction

1.1Description

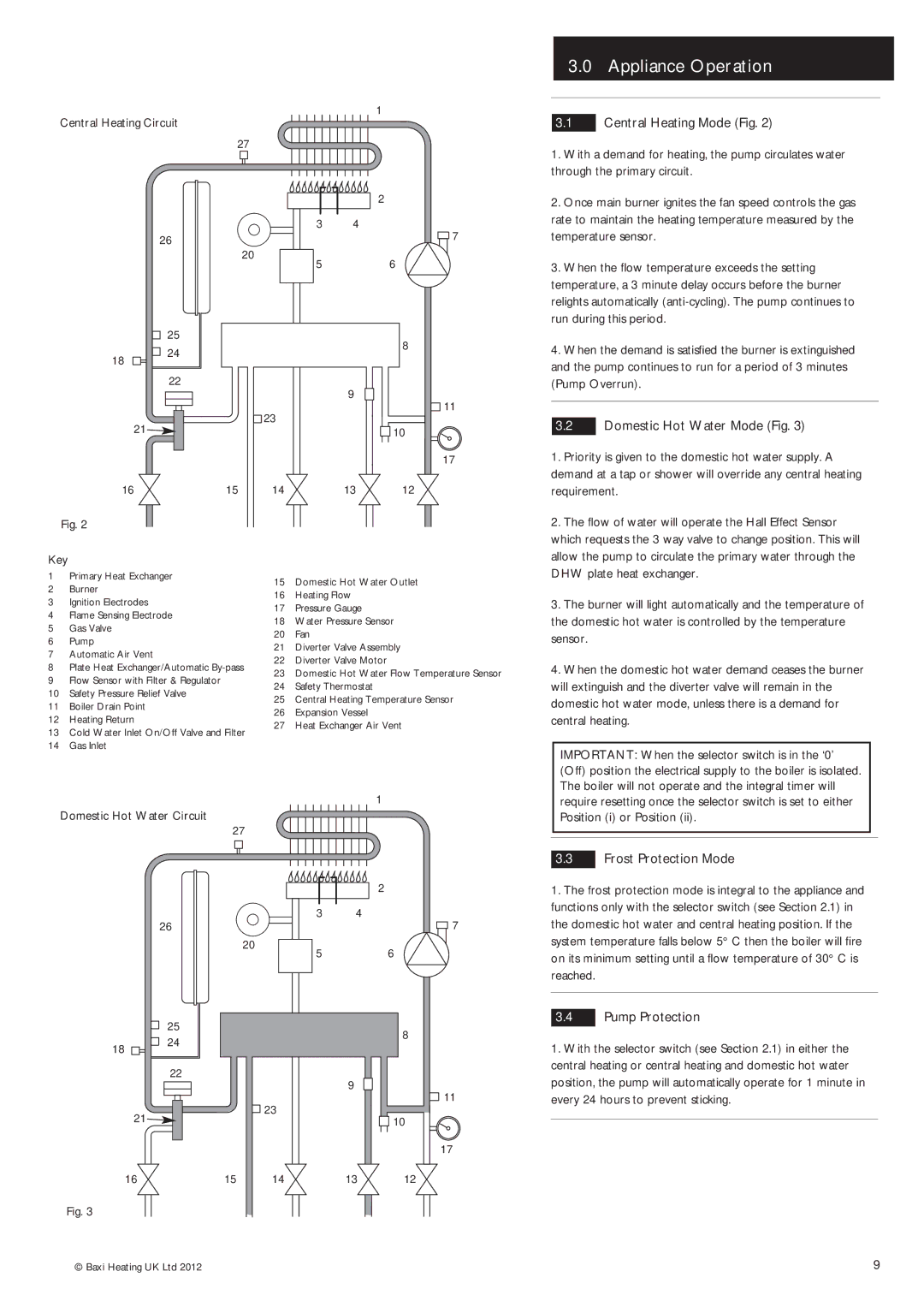

1.The Potterton Gold Combi HE A is a fully automatic gas fired wall mounted condensing combination boiler. It is room sealed and fan assisted, and will serve central heating and mains fed domestic hot water.

2.The boiler is set to give a maximum output of :-

24 models - | 24 kW DHW |

| 21 kW CH (Condensing) |

28 models - | 28 kW DHW |

| 25.9 kW CH (Condensing) |

33 models - | 33 kW DHW |

30.3kW CH (Condensing)

3.It is designed for use on Natural Gas (G20).

4.The boiler is suitable for use only on fully pumped sealed heating systems. Priority is given to domestic hot water.

5.The boiler is supplied with a filling loop and integral timer.

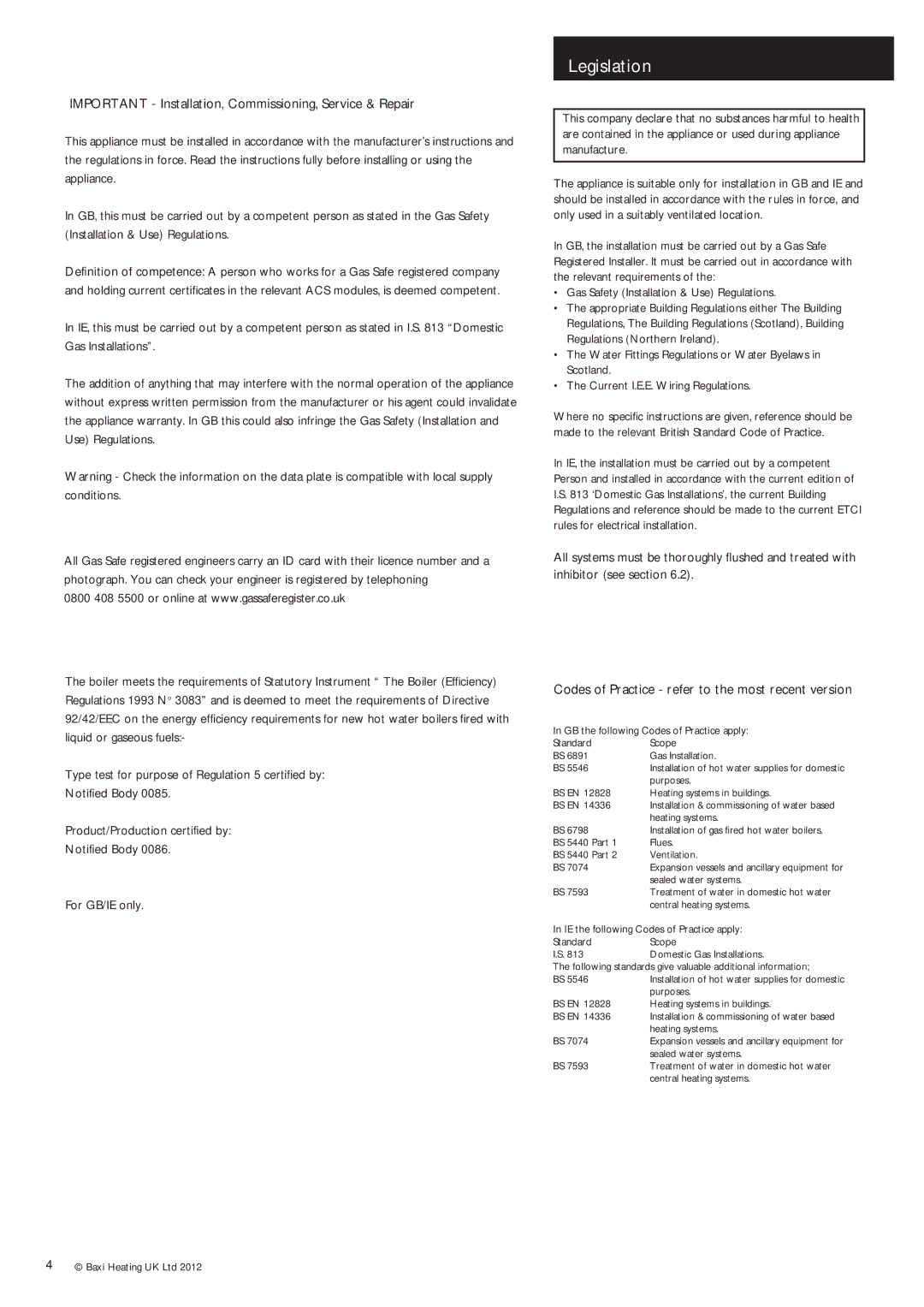

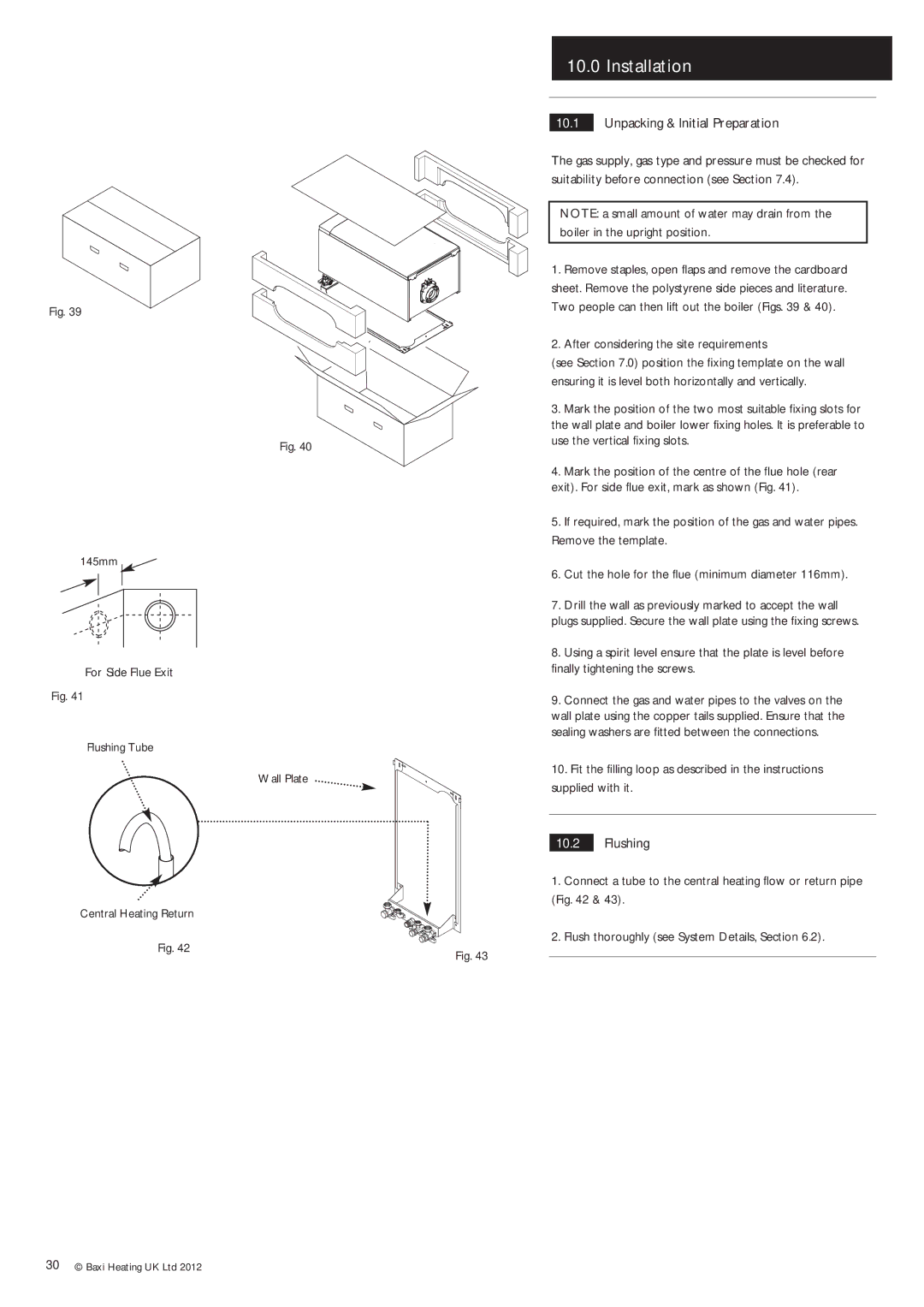

6.The boiler data badge gives details of the model, serial number and Gas Council number and is situated on the inner door panel. It is visible when the case front panel is removed (Fig. 1).

7.The boiler model name and serial number are also shown on the information label on the rear or the lower door panel. This is for user reference.

8.The boiler is intended to be installed in residential / commercial / light industrial E.M.C. environments on a governed meter supply only.

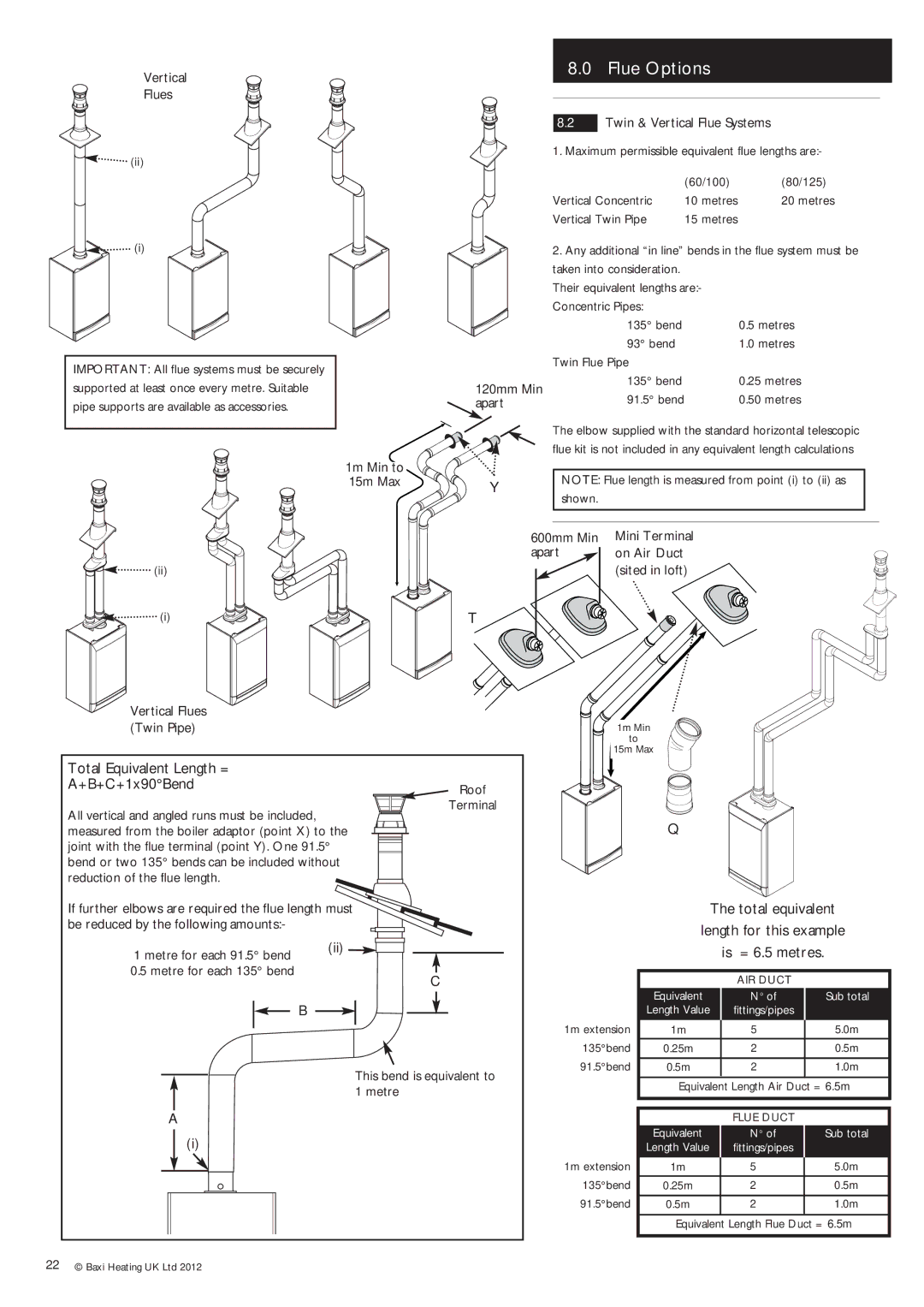

9.The boiler must be installed with one of the purpose designed flues such as the standard horizontal flue kit, part no. 5118489.

9.All systems must be thoroughly flushed and treated with inhibitor (see section 6.2).

1.2Contents of Pack

1.Boiler Unit

2.Wall Plate (inc. taps)

3.Set of Pipes (inc. nuts)

4.Template & Quick Fit Guide

5.Timer Blanking Plate Kit

6.Literature Pack

7.Filling Loop

© Baxi Heating UK Ltd 2012 | 7 |