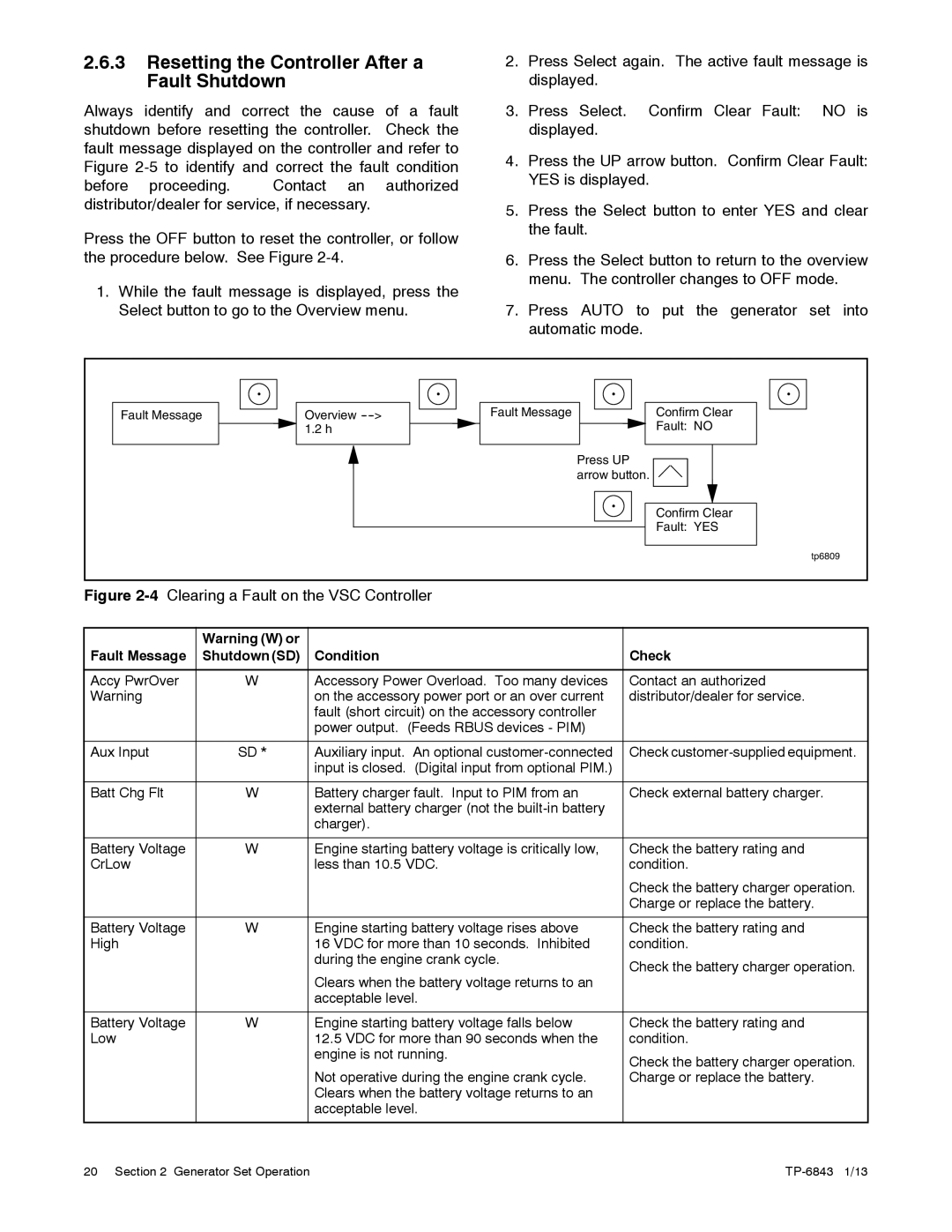

2.6.3Resetting the Controller After a Fault Shutdown

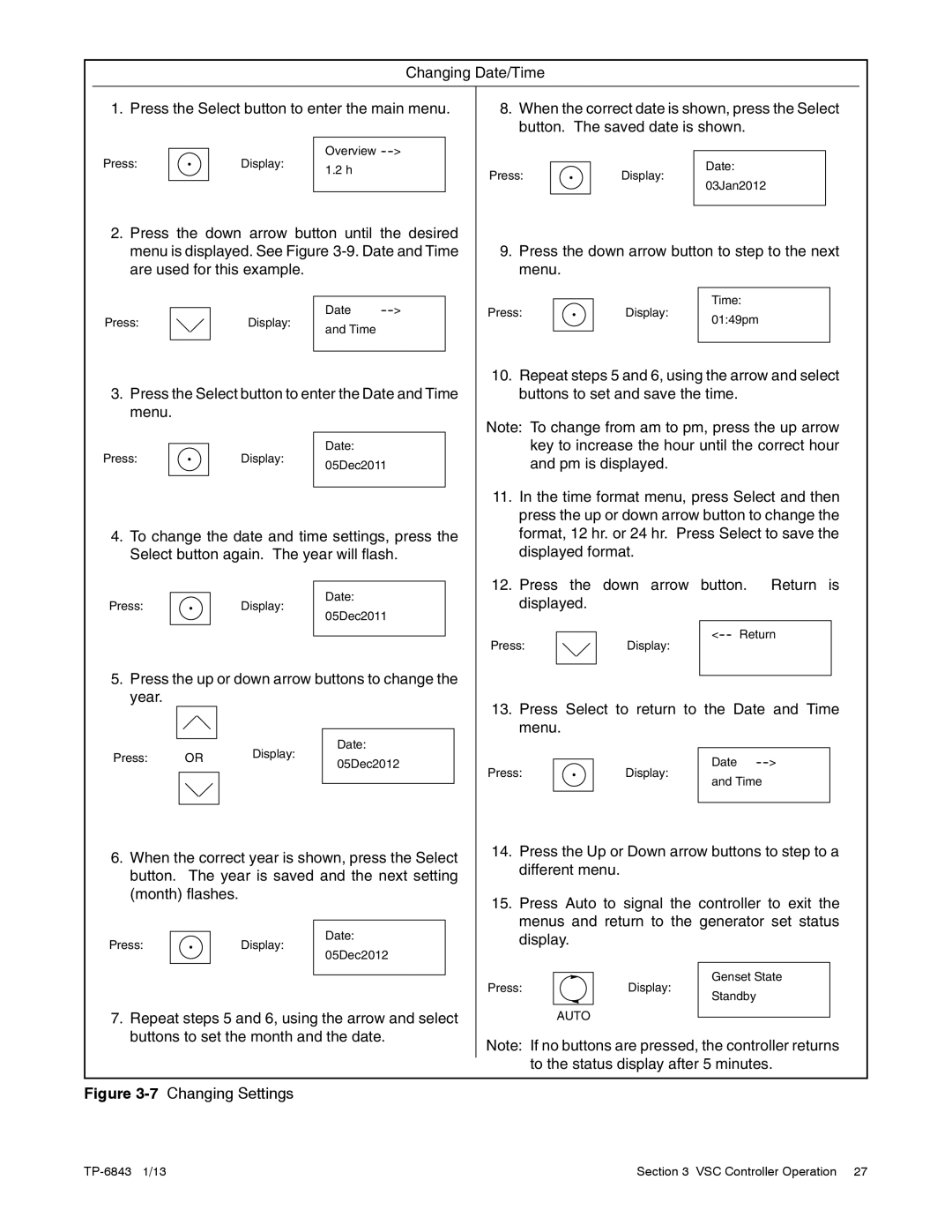

Always identify and correct the cause of a fault shutdown before resetting the controller. Check the fault message displayed on the controller and refer to Figure

before proceeding. Contact an authorized distributor/dealer for service, if necessary.

Press the OFF button to reset the controller, or follow the procedure below. See Figure

1.While the fault message is displayed, press the Select button to go to the Overview menu.

2.Press Select again. The active fault message is displayed.

3.Press Select. Confirm Clear Fault: NO is displayed.

4.Press the UP arrow button. Confirm Clear Fault: YES is displayed.

5.Press the Select button to enter YES and clear the fault.

6.Press the Select button to return to the overview menu. The controller changes to OFF mode.

7.Press AUTO to put the generator set into automatic mode.

Fault Message | Overview | Fault Message | Confirm Clear |

| 1.2 h |

| Fault: NO |

|

|

| Press UP |

|

|

| arrow button. |

|

|

| Confirm Clear |

|

|

| Fault: YES |

|

|

| tp6809 |

Figure 2-4 Clearing a Fault on the VSC Controller

| Warning (W) or |

|

|

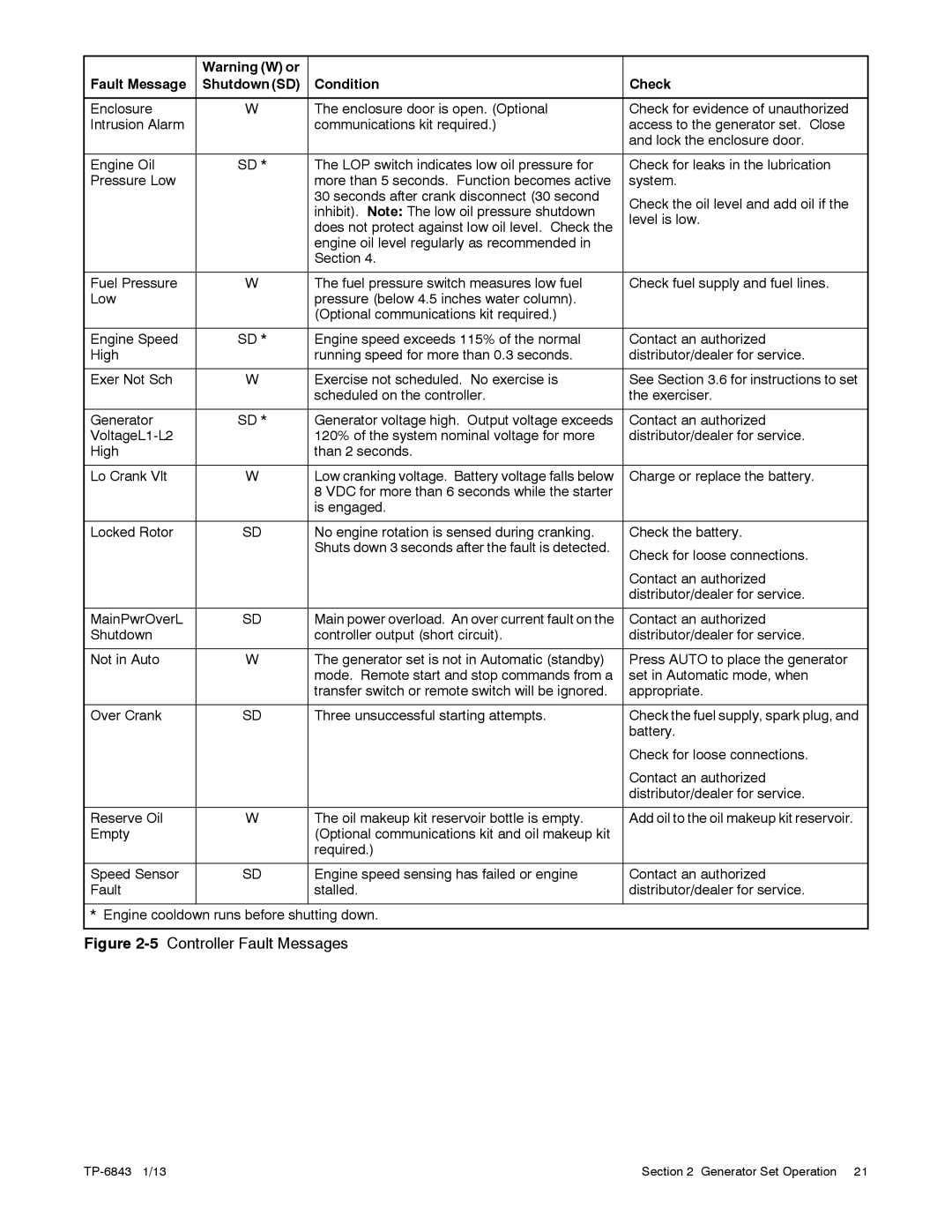

Fault Message | Shutdown(SD) | Condition | Check |

|

|

|

|

Accy PwrOver | W | Accessory Power Overload. Too many devices | Contact an authorized |

Warning |

| on the accessory power port or an over current | distributor/dealer for service. |

|

| fault (short circuit) on the accessory controller |

|

|

| power output. (Feeds RBUS devices - PIM) |

|

|

|

|

|

Aux Input | SD * | Auxiliary input. An optional | Check |

|

| input is closed. (Digital input from optional PIM.) |

|

|

|

|

|

Batt Chg Flt | W | Battery charger fault. Input to PIM from an | Check external battery charger. |

|

| external battery charger (not the |

|

|

| charger). |

|

|

|

|

|

Battery Voltage | W | Engine starting battery voltage is critically low, | Check the battery rating and |

CrLow |

| less than 10.5 VDC. | condition. |

|

|

| Check the battery charger operation. |

|

|

| Charge or replace the battery. |

|

|

|

|

Battery Voltage | W | Engine starting battery voltage rises above | Check the battery rating and |

High |

| 16 VDC for more than 10 seconds. Inhibited | condition. |

|

| during the engine crank cycle. | Check the battery charger operation. |

|

| Clears when the battery voltage returns to an | |

|

|

| |

|

| acceptable level. |

|

|

|

|

|

Battery Voltage | W | Engine starting battery voltage falls below | Check the battery rating and |

Low |

| 12.5 VDC for more than 90 seconds when the | condition. |

|

| engine is not running. | Check the battery charger operation. |

|

| Not operative during the engine crank cycle. | |

|

| Charge or replace the battery. | |

|

| Clears when the battery voltage returns to an |

|

|

| acceptable level. |

|

|

|

|

|

20 Section 2 Generator Set Operation |