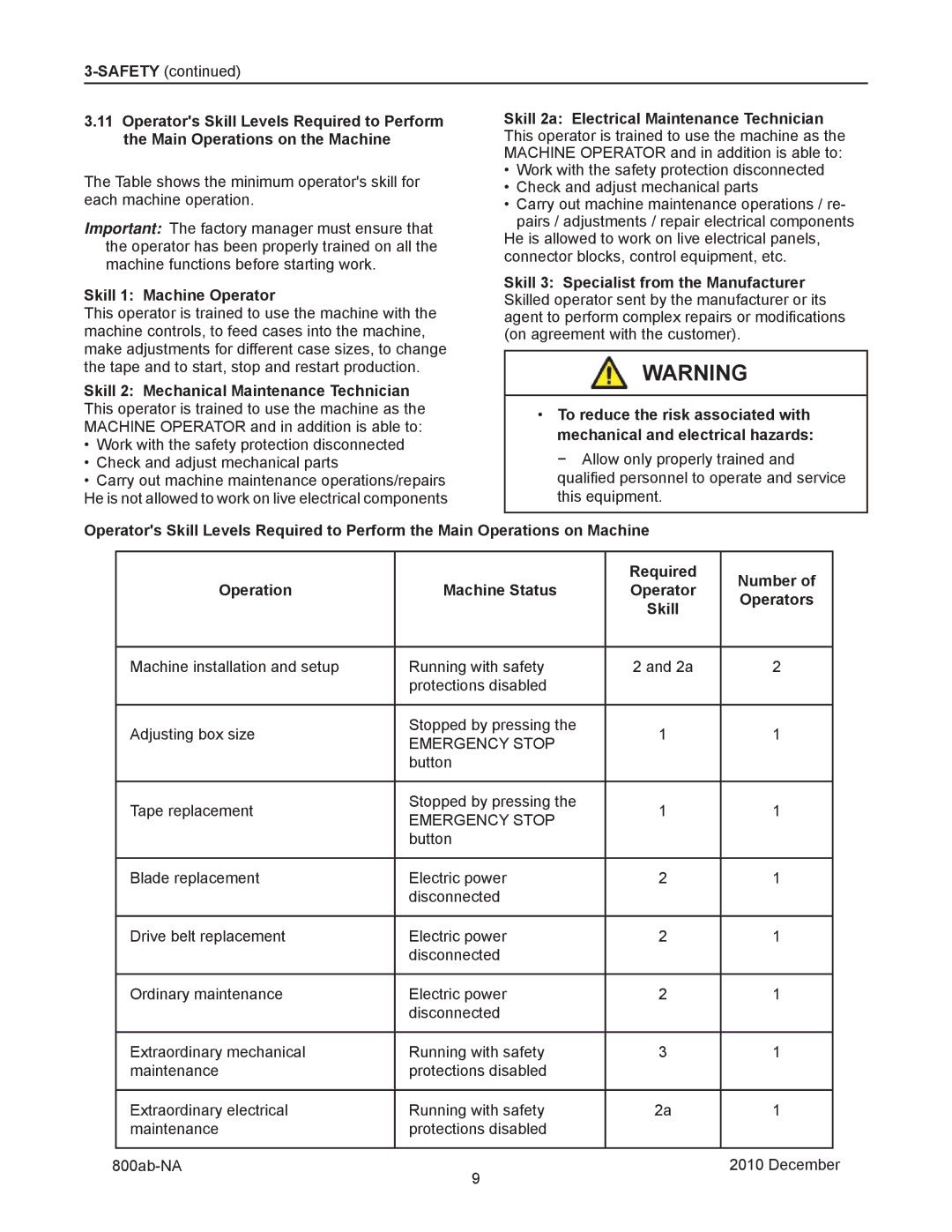

3.11Operator's Skill Levels Required to Perform the Main Operations on the Machine

The Table shows the minimum operator's skill for each machine operation.

Important: The factory manager must ensure that the operator has been properly trained on all the machine functions before starting work.

Skill 1: Machine Operator

This operator is trained to use the machine with the machine controls, to feed cases into the machine, make adjustments for different case sizes, to change the tape and to start, stop and restart production.

Skill 2: Mechanical Maintenance Technician This operator is trained to use the machine as the MACHINE OPERATOR and in addition is able to:

•Work with the safety protection disconnected

•Check and adjust mechanical parts

•Carry out machine maintenance operations/repairs He is not allowed to work on live electrical components

Skill 2a: Electrical Maintenance Technician This operator is trained to use the machine as the MACHINE OPERATOR and in addition is able to:

•Work with the safety protection disconnected

•Check and adjust mechanical parts

•Carry out machine maintenance operations / re- pairs / adjustments / repair electrical components

He is allowed to work on live electrical panels, connector blocks, control equipment, etc.

Skill 3: Specialist from the Manufacturer Skilled operator sent by the manufacturer or its agent to perform complex repairs or modifications (on agreement with the customer).

WARNING

•To reduce the risk associated with mechanical and electrical hazards:

−Allow only properly trained and

qualified personnel to operate and service this equipment.

Operator's Skill Levels Required to Perform the Main Operations on Machine

|

| Required | Number of | |

Operation | Machine Status | Operator | ||

Operators | ||||

|

| Skill | ||

|

|

| ||

|

|

|

| |

Machine installation and setup | Running with safety | 2 and 2a | 2 | |

| protections disabled |

|

| |

|

|

|

| |

Adjusting box size | Stopped by pressing the | 1 | 1 | |

EMERGENCY STOP | ||||

|

|

| ||

| button |

|

| |

|

|

|

| |

Tape replacement | Stopped by pressing the | 1 | 1 | |

EMERGENCY STOP | ||||

|

|

| ||

| button |

|

| |

|

|

|

| |

Blade replacement | Electric power | 2 | 1 | |

| disconnected |

|

| |

|

|

|

| |

Drive belt replacement | Electric power | 2 | 1 | |

| disconnected |

|

| |

|

|

|

| |

Ordinary maintenance | Electric power | 2 | 1 | |

| disconnected |

|

| |

|

|

|

| |

Extraordinary mechanical | Running with safety | 3 | 1 | |

maintenance | protections disabled |

|

| |

|

|

|

| |

Extraordinary electrical | Running with safety | 2a | 1 | |

maintenance | protections disabled |

|

| |

|

|

|

|

2010 December | |

| 9 |