Maintenance (Continued)

WARNING

•To reduce the risk associated with shear, pinch, and entanglement hazards:

−Turn air and electrical supplies off on associated equipment before performing any adjustments, maintenance, or servicing the taping heads

−Never attempt to work on the taping head or load tape while the box drive system is running

•To reduce the risk associated with sharp blade hazards:

−Keep hands and fingers away from tape cutoff blades under orange blade guards. The blades are extremely sharp

Cleaning

Regular slotted containers produce a great deal of dust and paper chips when conveyed through taping heads. If this dust is allowed to

Note – Never attempt to remove dirt from taping heads by blowing it out with compressed air. This can cause the dirt to be blown inside the components onto sliding surfaces.

Dirt in these areas can cause serious equipment damage. Never wash down or subject taping heads to conditions causing moisture condensation on components. Serious equipment damage could result.

Applying/Buff ng Roller Replacement

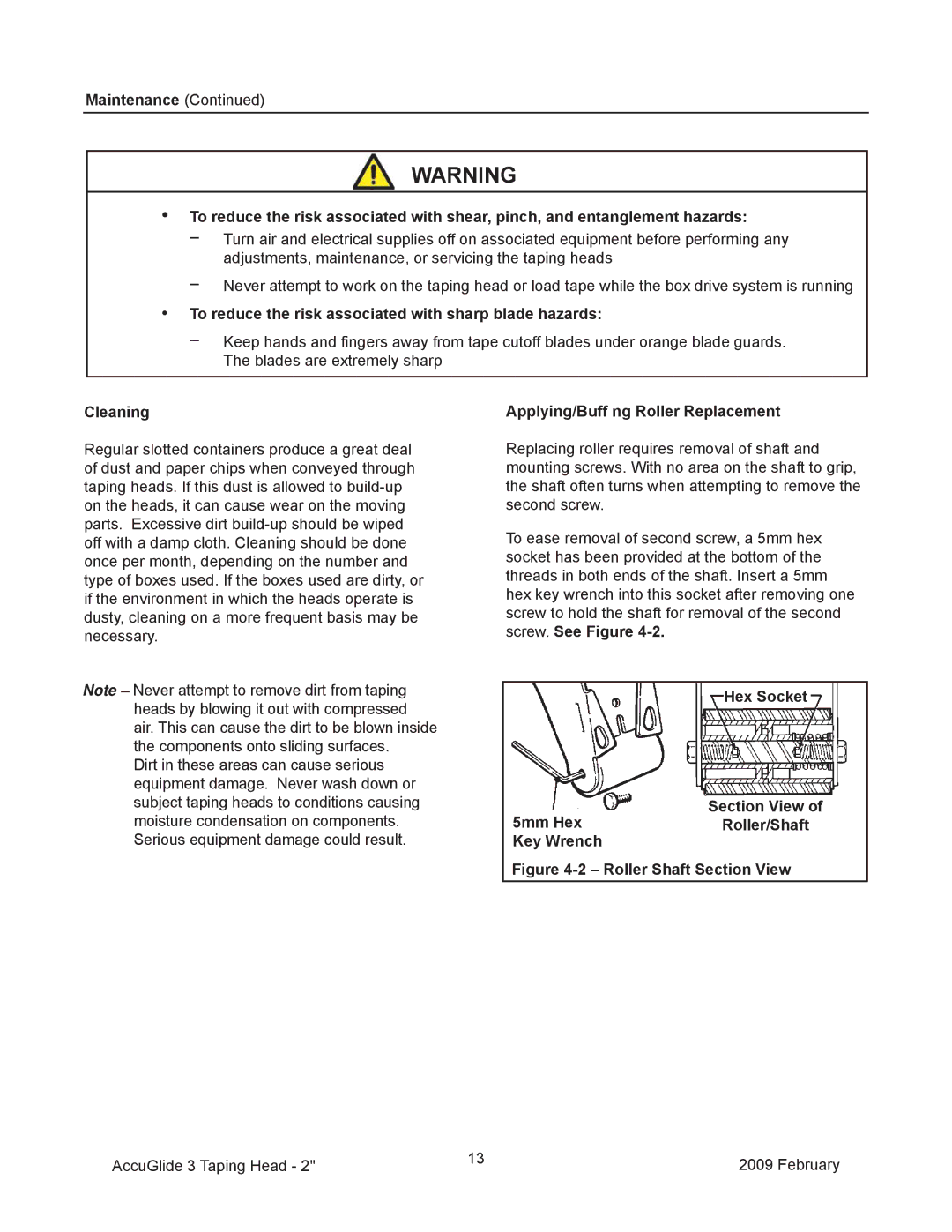

Replacing roller requires removal of shaft and mounting screws. With no area on the shaft to grip, the shaft often turns when attempting to remove the second screw.

To ease removal of second screw, a 5mm hex socket has been provided at the bottom of the threads in both ends of the shaft. Insert a 5mm hex key wrench into this socket after removing one screw to hold the shaft for removal of the second screw. See Figure

Hex Socket

Section View of

5mm HexRoller/Shaft Key Wrench

Figure 4-2 – Roller Shaft Section View

AccuGlide 3 Taping Head - 2" | 13 | 2009 February |

|