Special

13.11.3 Chain Removal

![]() WARNING

WARNING

•To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or servicing the machine or taping heads

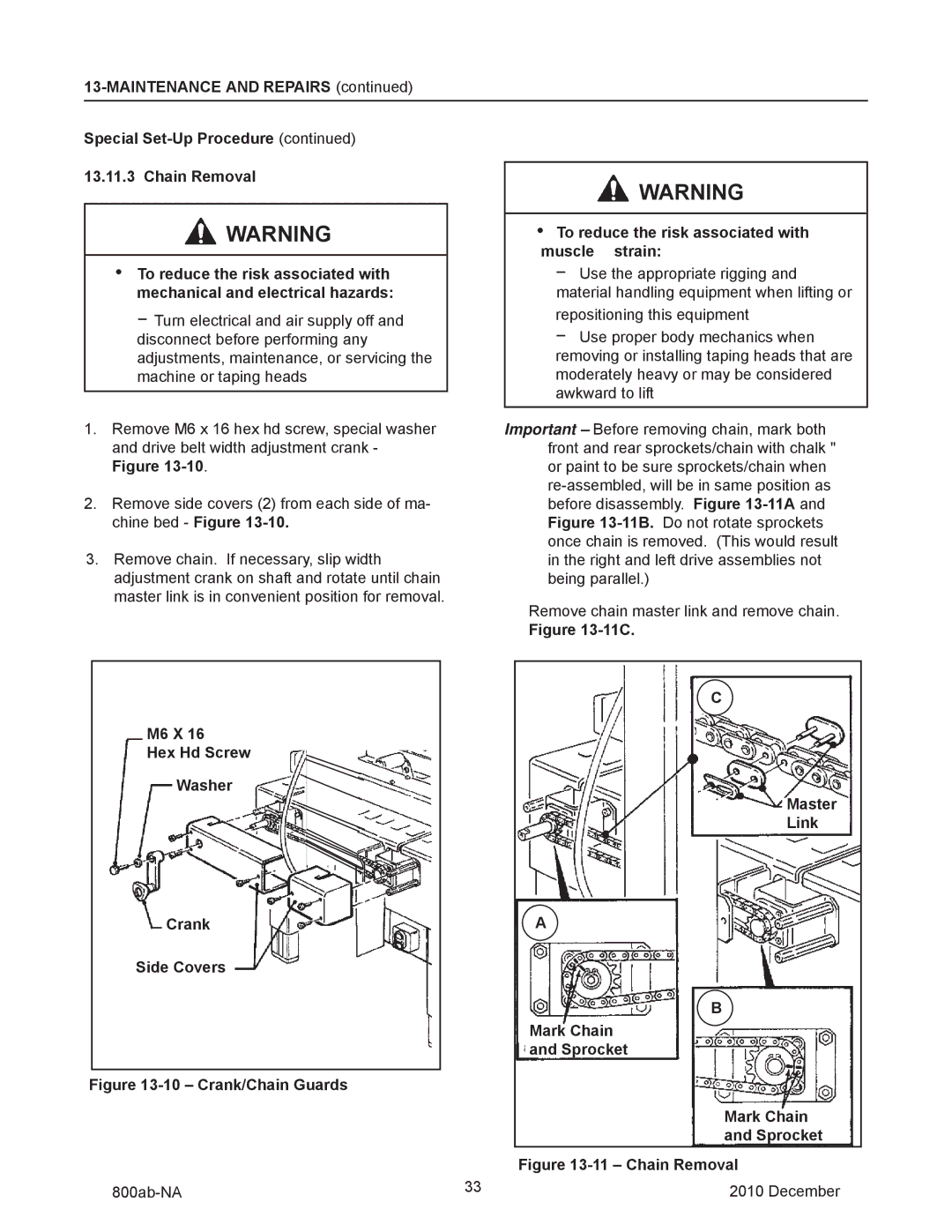

1.Remove M6 x 16 hex hd screw, special washer and drive belt width adjustment crank -

Figure

2.Remove side covers (2) from each side of ma- chine bed - Figure

3.Remove chain. If necessary, slip width adjustment crank on shaft and rotate until chain master link is in convenient position for removal.

M6 X 16

Hex Hd Screw

Washer

Crank

Side Covers

Figure 13-10 – Crank/Chain Guards

33 | |

|

![]() WARNING

WARNING

•To reduce the risk associated with muscle strain:

−Use the appropriate rigging and material handling equipment when lifting or repositioning this equipment

−Use proper body mechanics when removing or installing taping heads that are moderately heavy or may be considered awkward to lift

Important – Before removing chain, mark both front and rear sprockets/chain with chalk " or paint to be sure sprockets/chain when

Remove chain master link and remove chain.

Figure 13-11C.

C

Master

Link

A

B

Mark Chain

and Sprocket

Mark Chain

and Sprocket

Figure 13-11 – Chain Removal

2010 December