12-OPERATION

12.1Operator's Correct Working Position and Operational Flow (Figure

Figure

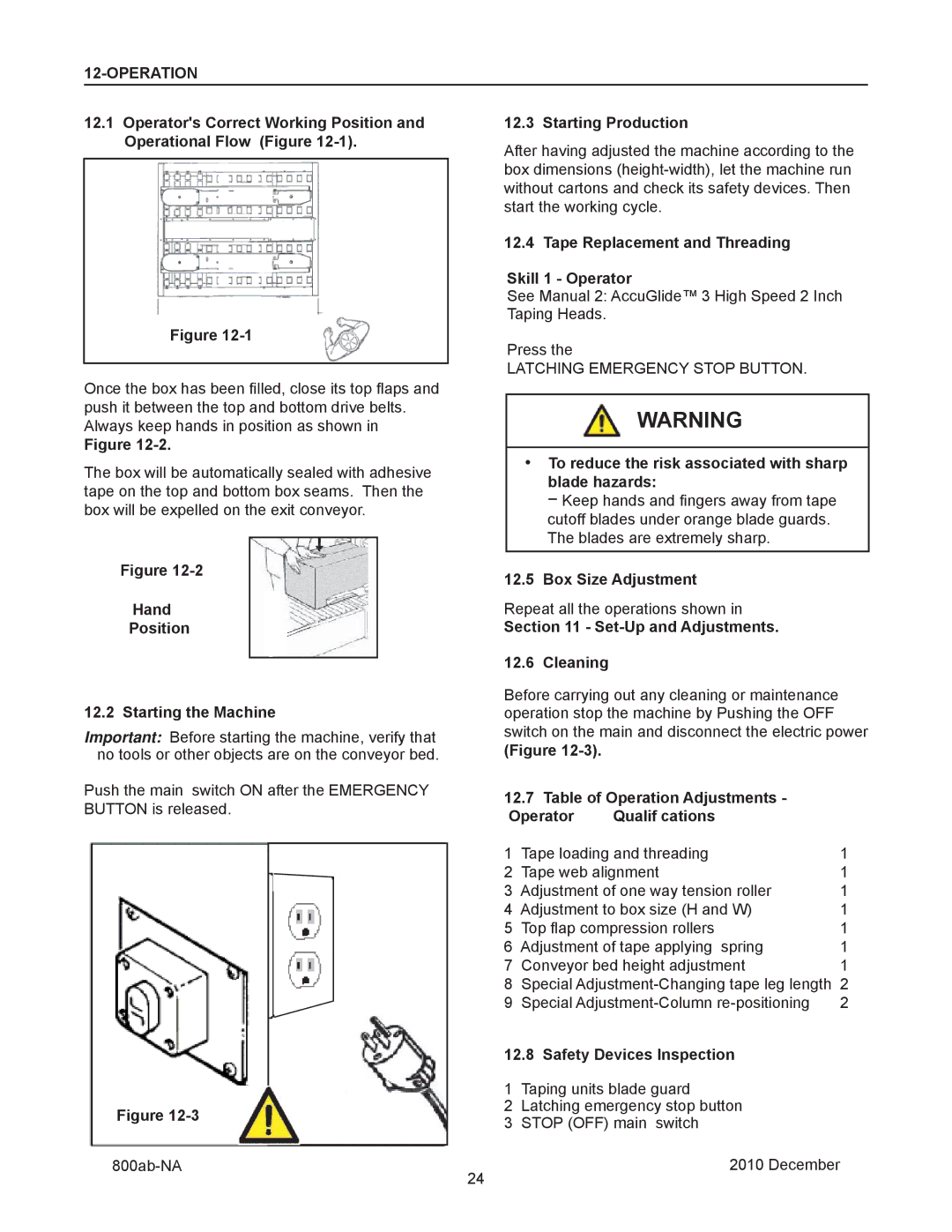

Once the box has been filled, close its top flaps and push it between the top and bottom drive belts. Always keep hands in position as shown in

Figure

The box will be automatically sealed with adhesive tape on the top and bottom box seams. Then the box will be expelled on the exit conveyor.

Figure

Hand

Position

12.3 Starting Production

After having adjusted the machine according to the box dimensions

12.4 Tape Replacement and Threading

Skill 1 - Operator

See Manual 2: AccuGlide™ 3 High Speed 2 Inch Taping Heads.

Press the

LATCHING EMERGENCY STOP BUTTON.

WARNING

•To reduce the risk associated with sharp blade hazards:

− Keep hands and fingers away from tape cutoff blades under orange blade guards. The blades are extremely sharp.

12.5 Box Size Adjustment

Repeat all the operations shown in

Section 11 - Set-Up and Adjustments.

12.6 Cleaning

12.2 Starting the Machine

Important: Before starting the machine, verify that no tools or other objects are on the conveyor bed.

Push the main switch ON after the EMERGENCY BUTTON is released.

Figure

Before carrying out any cleaning or maintenance operation stop the machine by Pushing the OFF switch on the main and disconnect the electric power

(Figure

12.7 Table of Operation Adjustments - |

| ||

Operator | Qualif cations |

| |

1 | Tape loading and threading | 1 | |

2 | Tape web alignment | 1 | |

3 | Adjustment of one way tension roller | 1 | |

4 | Adjustment to box size (H and W) | 1 | |

5 | Top flap compression rollers | 1 | |

6 | Adjustment of tape applying spring | 1 | |

7 | Conveyor bed height adjustment | 1 | |

8 | Special | 2 | |

9 | Special | 2 | |

12.8 Safety Devices Inspection

1Taping units blade guard

2Latching emergency stop button

3STOP (OFF) main switch

24

2010 December