|

|

|

| One Way |

|

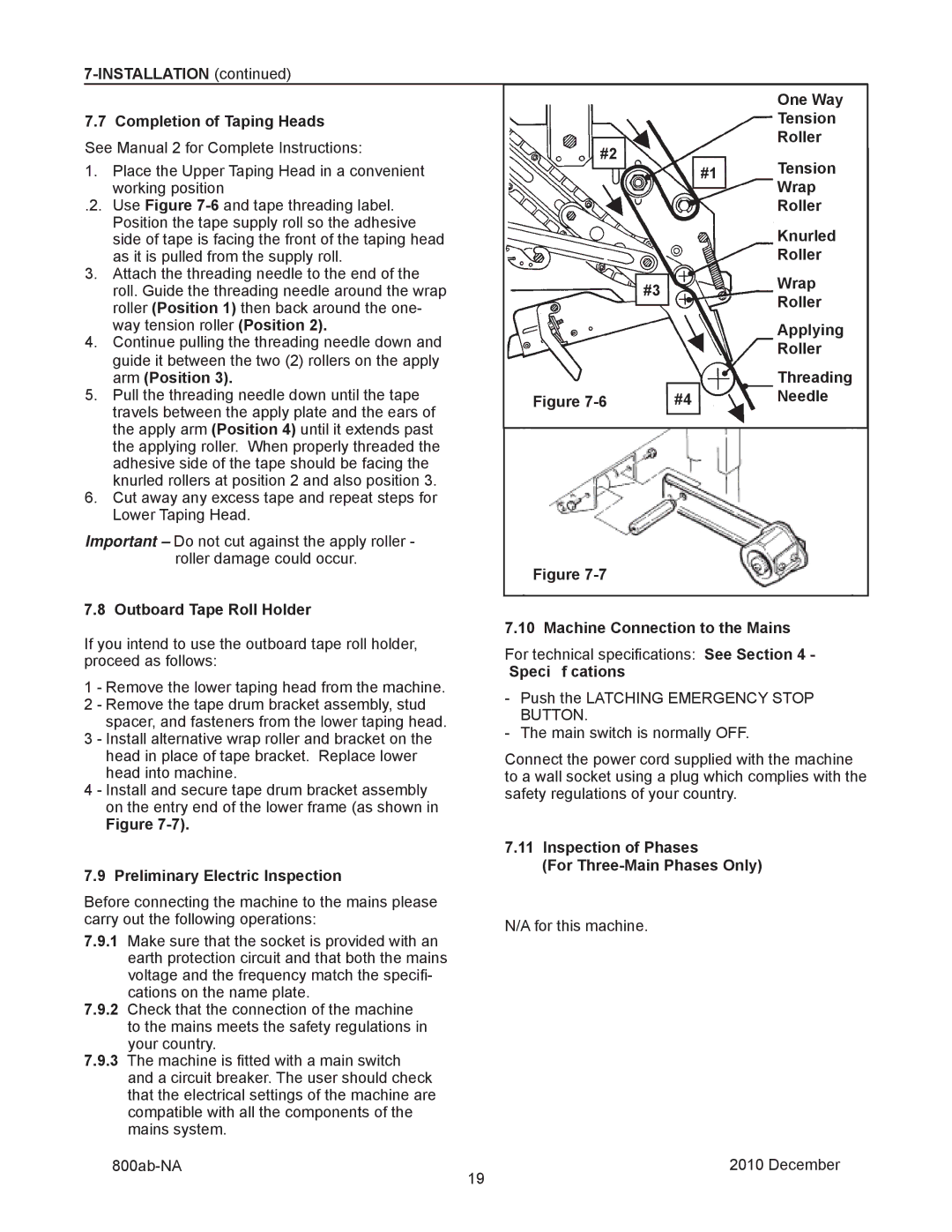

7.7 Completion of Taping Heads |

|

| Tension |

| |

See Manual 2 for Complete Instructions: | #2 |

| Roller |

| |

| Tension |

| |||

1. | Place the Upper Taping Head in a convenient | #1 |

| ||

|

| ||||

| working position |

|

| Wrap |

|

.2. Use Figure |

|

| Roller |

| |

| Position the tape supply roll so the adhesive |

|

| Knurled |

|

| side of tape is facing the front of the taping head |

|

|

| |

| as it is pulled from the supply roll. |

|

| Roller |

|

3. Attach the threading needle to the end of the |

| #3 | Wrap |

| |

| roll. Guide the threading needle around the wrap |

|

| ||

|

| Roller |

| ||

| roller (Position 1) then back around the one- |

|

|

| |

| way tension roller (Position 2). |

|

| Applying |

|

4. Continue pulling the threading needle down and |

|

| Roller |

| |

| guide it between the two (2) rollers on the apply |

|

|

| |

|

|

| Threading |

| |

| arm (Position 3). |

|

|

| |

5. Pull the threading needle down until the tape | Figure | #4 | Needle |

| |

| travels between the apply plate and the ears of |

|

|

|

|

| the apply arm (Position 4) until it extends past |

|

|

|

|

|

|

|

|

| |

| the applying roller. When properly threaded the |

|

|

|

|

| adhesive side of the tape should be facing the |

|

|

|

|

| knurled rollers at position 2 and also position 3. |

|

|

|

|

6.Cut away any excess tape and repeat steps for Lower Taping Head.

Important – Do not cut against the apply roller - roller damage could occur.

Figure

7.8 Outboard Tape Roll Holder

If you intend to use the outboard tape roll holder, | 7.10 Machine Connection to the Mains | ||

For technical specifications: See Section 4 - | |||

proceed as follows: | |||

Speci f cations | |||

1 - Remove the lower taping head from the machine. | |||

- Push the LATCHING EMERGENCY STOP | |||

2 - Remove the tape drum bracket assembly, stud | |||

BUTTON. | |||

spacer, and fasteners from the lower taping head. | |||

- The main switch is normally OFF. | |||

3 - Install alternative wrap roller and bracket on the | |||

head in place of tape bracket. Replace lower | Connect the power cord supplied with the machine | ||

head into machine. | to a wall socket using a plug which complies with the | ||

4 - Install and secure tape drum bracket assembly | safety regulations of your country. | ||

on the entry end of the lower frame (as shown in |

| ||

Figure |

| ||

|

| 7.11 Inspection of Phases | |

7.9 Preliminary Electric Inspection | (For | ||

| |||

Before connecting the machine to the mains please |

| ||

carry out the following operations: | N/A for this machine. | ||

7.9.1 | Make sure that the socket is provided with an | ||

| |||

| earth protection circuit and that both the mains |

| |

| voltage and the frequency match the specifi- |

| |

7.9.2 | cations on the name plate. |

| |

Check that the connection of the machine |

| ||

| to the mains meets the safety regulations in |

| |

7.9.3 | your country. |

| |

The machine is fitted with a main switch |

| ||

| and a circuit breaker. The user should check |

| |

| that the electrical settings of the machine are |

| |

| compatible with all the components of the |

| |

| mains system. |

| |

2010 December | |||

|

| 19 | |