Programming Guide

Agilent Part No Microfiche Part No Update April

Safety Guidelines

Contents

Abor

Status Reporting

Error Messages

Synchronizing Power Module Output Changes

External References

Introduction

About This Guide

Documentation Summary

Supported Applications

VXIplug&play Power Products Instrument Drivers

Downloading and Installing the Driver

Accessing Online Help

Introduction To Scpi

Gpib Capabilities Of The Power Module

Introduction To Programming

Module Gpib Address

RST *IDN? *SRE

Voltlev 8.0 Prot 8.8 CURR?

Volt LEV Prot Curr

Outpprotdel

Effect of Optional Headers

Traversing the Command Tree

Volttrig 7.5INIT*TRG Outp OFF*RCL 2OUTP on

Outputprotectionclear STATUSOPERATIONCONDITION?

OUTPUTPROTECTIONCLEARSTATUSOPERATIONCONDITION?

Voltagelevel 7PROTECTION 8CURRENTLEVEL 3MODE List

Suffixes and Multipliers Class Unit Unit with Multiplier

Symbol

Numerical Data Formats Talking Formats

Listening Formats

Assign @PM3TO

System Considerations

Agilent Basic Controllers

Error Handling

Using the National Instruments Gpib Interface

Sending the Command Volt 5 in C

Sending the Command Volt 5 in Basic

Receiving Module Data with Basic

Receiving Data from the Module

Receiving Module Data with C

Introduction

Language Dictionary

Description

Description Of Common Commands

CLS

Meaning and Type

ESR?

Bit Configuration of Standard Event Status Enable Register

ESE

ESE

IDN?

OPC

OPC?

PSC

OPT?

RCL

RCL

RST

SAV

SRE

SRE

Bit Configuration of Status Byte Register

STB?

TRG

Abor

Description of Subsystem Commands

TST?

WAI

Calauto

Subsystem Tree Diagram Calibration Subsystem

Calpass

Calauto 1 Calauto Once

Calcurr

Calcurrlev

Calvoltlev

Calsave

Calstat

Calvolt

Currmode

Calvoltprot

Curr

Curr 500 MA Currlev

Currtrig 1200 MA Currlevtrig

Currprotstat

Currprotstat OFF

Currtrig

Listcurr

Init Initcont 1 Initcont on

Listcoun

Listcoun Listcoun INF

Liststep

LISTCURRPOIN?

Listdwel

LISTDWELPOIN?

MEASCURR? MEASVOLT?

Listvolt

Listvolt 2.0,2.5,3.0 Listvolt MAX,2.5,MIN

LISTVOLTPOIN?

Outpprot

Outp Outpstat ON,NORELAY

Norm

Outpprotcle Outpprotdel 75E-1

Outprel

Outprelpol

Outpttltsour Link

Outpttlt

Outpttlt 1 Outpttlt OFF

Outpttltlink

Statoperenab

STATOPER?

STATOPEREVEN?

STATOPERCOND?

Statpres

Stat Oper NTR 32 Stat Oper PTR

Stat Ques COND?

STATQUES?

STATQUESEVEN?

STATQUESCOND?

Trig

SYSTERR?

SYSTVERS?

Trigger Subsystem

Triglink

Trig Trig IMM

Trigdel

Trigdel .25 Trigdel MAX

Voltmode List Voltmode FIX

Volt

Voltlev

Voltmode

VOLTSENSSOUR?

Volttrig

Volttrig 1200 MV Voltlevtrig

Link Parameter List

Power Module Programming Parameters

Operation Status Group

Power Module Status Structure

Status Register Bit Configuration

Status Reporting

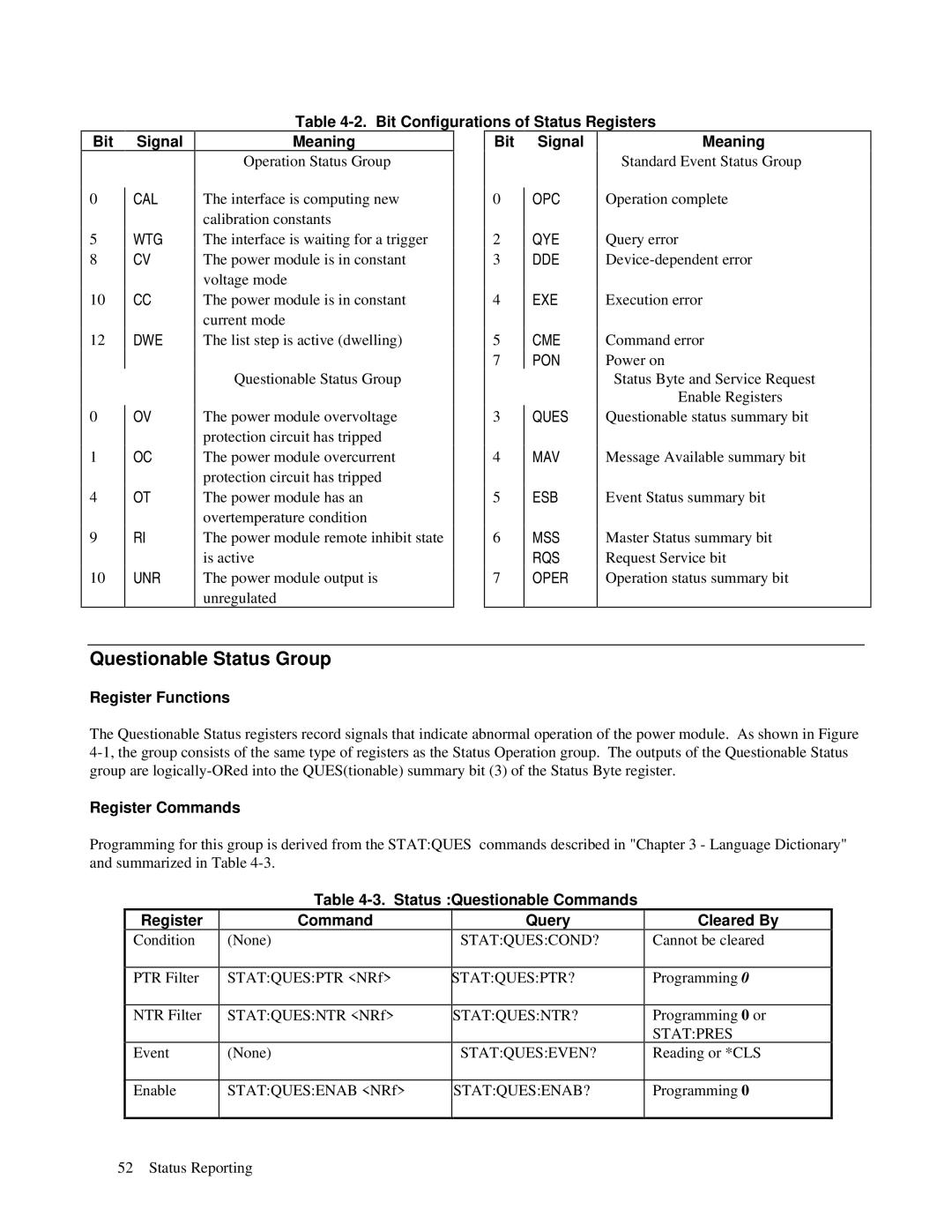

Bit Signal Bit Configurations of Status Registers Meaning

Status Questionable Commands Query

Questionable Status Group

Standard Event Status Group

Power Module Status Model

Status Byte Register

Output Queue

Location Of Event Handles

Examples

Initial Conditions At Power On

Statoperptr 1024NTR Statoperenab 1024*SRE

Statoperptr 5376ENAB

Statquesptr 18ENAB

STATOPEREVEN?QUESEVEN?

Synchronizing Power Module Output Changes

Trigger Subsystem

Model of Fixed-Mode Trigger Operation

Delaying State

Idle State

Initiated State

Output Change State

Model of List Mode Trigger Operation

INITiateCONTinuous Command

Trigger Status and Event Signals

Outpttltsour

List Subsystem

Triggering a List

Listvolt 3.0,3.25,3.5,3.75 Listdwel 10,10,25,40

Automatically Repeating a List

Listcurr 2,3,12,15

Timing diagrams of Liststep Operation

DFI Discrete Fault Indicator Subsystem

Scpi Command Completion

RI Remote Inhibit Subsystem

Standard Event Status Register Error Bits

Error Messages

Power Module Hardware Error Messages

System Error Messages

222 -223 -241 -310 -330 -350 -400 -410 -420 -430

Scpi Version

Scpi Confirmed Commands

Scpi Approved Commands

Scpi Conformance Information

Non-SCPI Commands

Application Programs

Application 1. Sequencing Multiple Modules During Power Up

Variations On This Implementation

Figure B1-1. Block Diagram of Application #1

Figure B1-2. Timing Diagram of Application #1

Enable Response to Trigger

Reset and Clear Module

Enable Backplane TTL Trigger Drive

Enable Output

Implementation Details How The MPS Implements The Solution

MPS Set Up

Figure B2-1. Block Diagram of Application #2

Start AT 15

When a CV-TO-CC Transition Occurs

Enable TTL Trigger Drive

Enable Response to TTL Trigger

Application 3. Controlling Output Voltage Ramp Up at Turn On

Figure B3-1. Simulating a Slow Voltage Ramp

Generating the Desired Voltage Ramp for Application #3

Seconds

Option Base

Start Voltage for Ramp

Stop Voltage for Ramp

Figure B4-1. Voltage Waveform for Application #4

Application 4. Providing Time-Varying Voltages

Module set up

Variations On This Implementation

Enables Detection on Positive TRANSITION, I.E

Enable OCP

No Delay Before Protection Occurs

Enable Detection of OC Condition

Application 5. Providing Time-Varying Current Limiting

Figure B5-1. Typical DUT Current vs. Time

Implementation Details How The MPS Implements The Sequence

SET to GET Current from List

GO to 12 V When Triggered

Current Limit Data

Dwell Time Data

Nominal 12

Application 6. Output Sequencing Paced by the Computer

MPS Set Up

Figure B6-1. Block Diagram of Application #6

Number of Bias Supply Limit C0MBINATIONS

These are the Bias

Supply Limit Conditions

To be Tested

Return

Overview Of Application

Advantages/Benefits Of The MPS Solution

Figure B7-1. Block Diagram of Application #7

Enable Intr Identify Handler Subroutine

When the Module Indicates SIC Step Completed

When IT Completes the LIST. OPC Generates SRO

Enable SRQ Interrupt

Supplemental Information

CMD$ = Voltmode List ‘ SET to GET Voltage from List

CMD$ = Output on ‘ Enable Output

CMD$ = Initiate ‘ Enable Trigger to Start List

‘ Conversion to Send Real Numbers Over the BUS

Wend

Call Iooutputs SLOTO, CMDS, L

Waiting for Trigger BIT 5 of the Operation Status Register

CONDITION.DATA =

‘ INSTRUMENT.NAME$ = Sloto

‘ Disable Auto Serial Poll

If IBSTA% 0 then Goto ‘ AS Part of the Command String

‘ Program N3.BAS

‘ General Error Handler

If IBSTA% 0 then Goto Selected AS a Trigger Source

Stop

Dwell = ramptime

Application #3 Controlling Voltage Ramp UP AT Turn on

To terminate the iooutputa

Int error Char *badstring If error !=

EOl enabled for both read and write

Strcatvlist, vpoint

This is a generalized error checking routine

Index

Index

Index

Index

Index

United States Latin America

Agilent Sales and Support Offices

Manual Updates