OPERATION

OPERATION

8. Driveline Length Check

Before operating the Implement, check to make sure the Implement input driveline will not bottom out or become disengaged. Bottoming out occurs when the inner shaft penetrates the outer housing until the assembly becomes

damage to the Tractor PTO by pushing the PTO into the Tractor and through the support bearings or downward onto the PTO shaft, breaking it off. A broken drive line can cause personal injury.

When fitting the mower to the tractor, the telescoping driveline must be inspected to ensure that at its most compressed position, the profiles do not “bottom out”, and when at its farthest extended position, there is sufficient engagement between the profiles to operate safely. At its shortest length, there must be at least a 1” clearance between each profile end and opposite profile universal joint. At its farthest operating extension, a minimum profile engagement of 12” must be maintained.

“Bottoming Out” Check Procedure

•Disconnect driveline from the tractor and slide the profiles together until fully compressed.

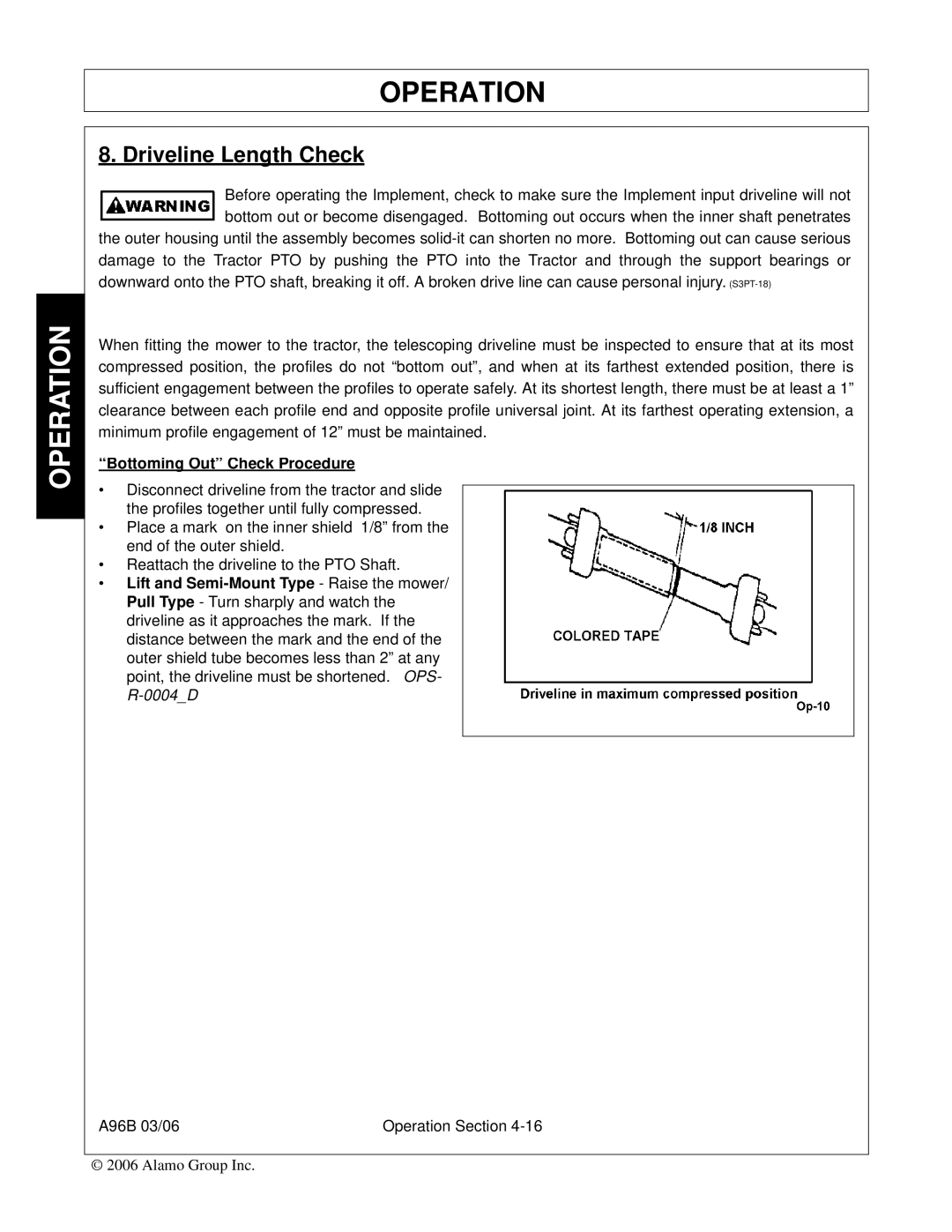

•Place a mark on the inner shield 1/8” from the end of the outer shield.

•Reattach the driveline to the PTO Shaft.

•Lift and

A96B 03/06 | Operation Section |

© 2006 Alamo Group Inc.