MAINTENANCE

MAINTENANCE

Step 8 Install shims if they were present at disassembly against back side gear. Total thickness for shims used on front and back side of input gear is.040.” Another method to determine amount of shims to place against back side is to measure thickness of shims on opposite side of gear and subtract total from.040. Never use shim less than.012 thick.

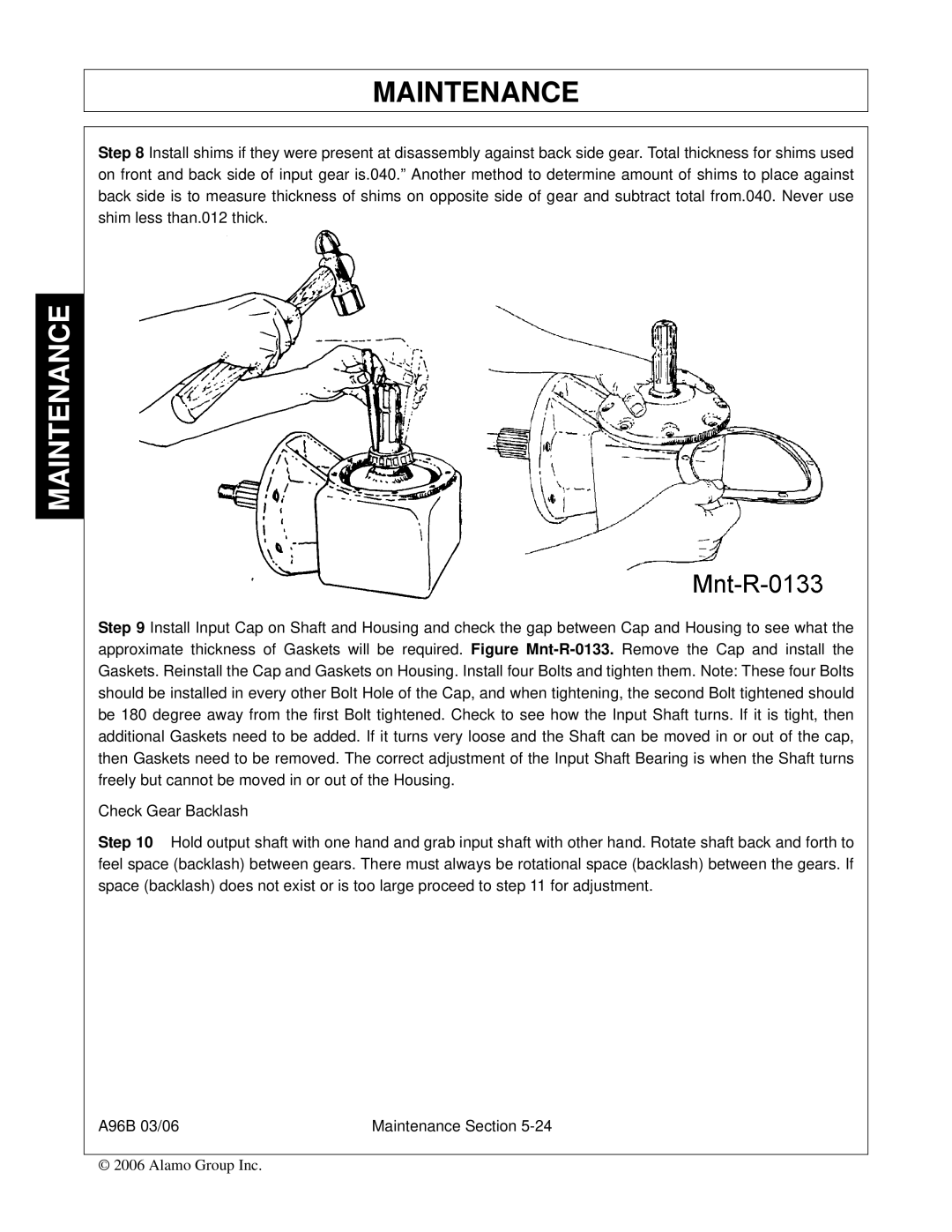

Step 9 Install Input Cap on Shaft and Housing and check the gap between Cap and Housing to see what the approximate thickness of Gaskets will be required. Figure

Check Gear Backlash

Step 10 Hold output shaft with one hand and grab input shaft with other hand. Rotate shaft back and forth to feel space (backlash) between gears. There must always be rotational space (backlash) between the gears. If space (backlash) does not exist or is too large proceed to step 11 for adjustment.

A96B 03/06 | Maintenance Section |

© 2006 Alamo Group Inc.