MEASUREMENT & INSPECTION

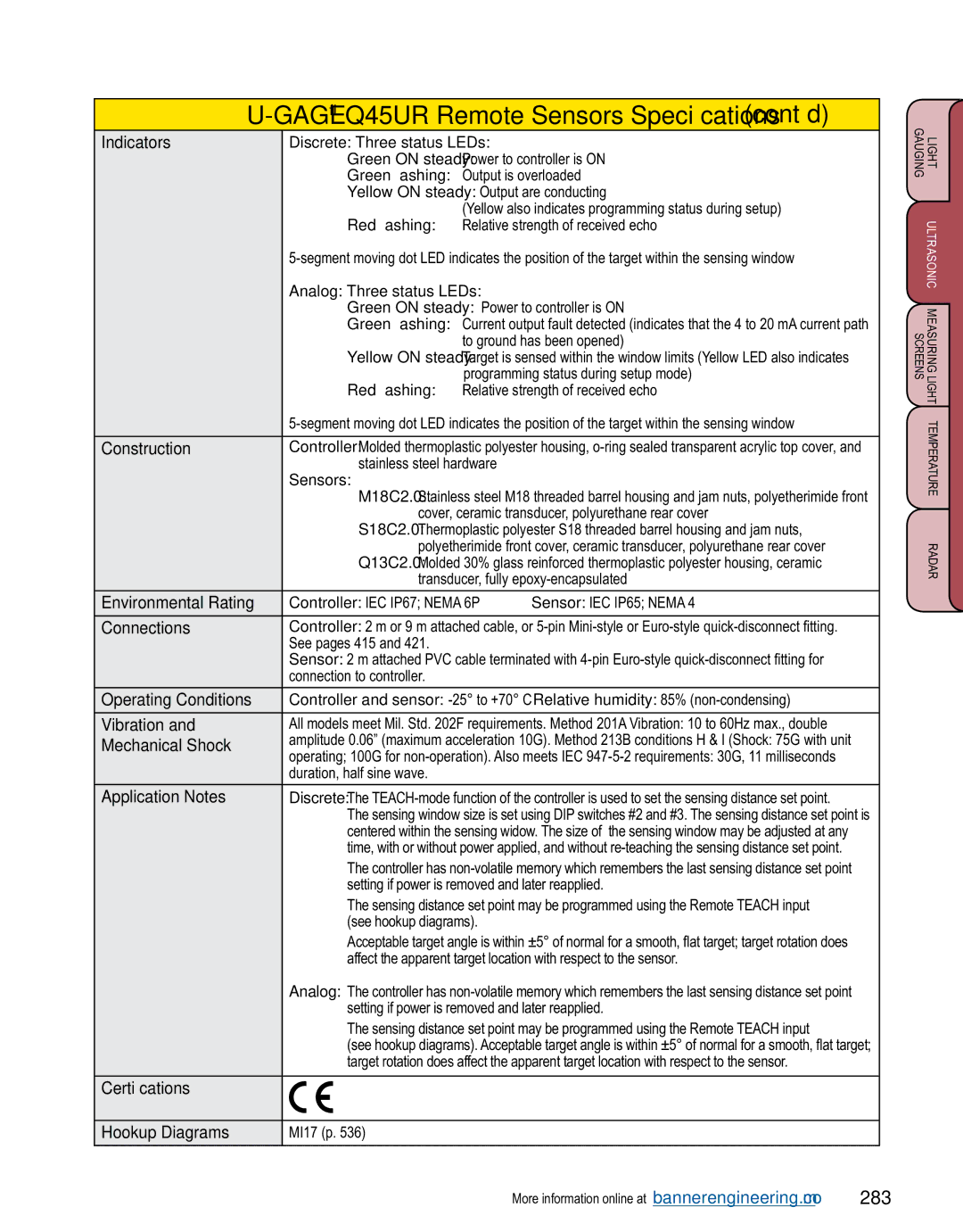

U-GAGE® Q45UR Remote Sensors Specifications (cont’d)

Indicators | Discrete: Three status LEDs: |

| ||

| Green ON steady: Power to controller is ON | |||

| Green flashing: | Output is overloaded | ||

| Yellow ON steady: Output are conducting | |||

| Red flashing: | (Yellow also indicates programming status during setup) | ||

| Relative strength of received echo | |||

| ||||

| Analog: Three status LEDs: |

|

| |

| Green ON steady: Power to controller is ON | |||

| Green flashing: | Current output fault detected (indicates that the 4 to 20 mA current path | ||

|

| to ground has been opened) | ||

| Yellow ON steady: Target is sensed within the window limits (Yellow LED also indicates | |||

| Red flashing: | programming status during setup mode) | ||

| Relative strength of received echo | |||

| ||||

|

| |||

Construction | Controller: Molded thermoplastic polyester housing, | |||

| stainless steel hardware |

| ||

| Sensors: |

|

| |

| M18C2.0: Stainless steel M18 threaded barrel housing and jam nuts, polyetherimide front | |||

| cover, ceramic transducer, polyurethane rear cover | |||

| S18C2.0: Thermoplastic polyester S18 threaded barrel housing and jam nuts, | |||

| polyetherimide front cover, ceramic transducer, polyurethane rear cover | |||

| Q13C2.0: Molded 30% glass reinforced thermoplastic polyester housing, ceramic | |||

| transducer, fully | |||

|

|

| ||

Environmental Rating | Controller: IEC IP67; NEMA 6P | Sensor: IEC IP65; NEMA 4 | ||

|

| |||

Connections | Controller: 2 m or 9 m attached cable, or | |||

| See pages 415 and 421. |

|

| |

| Sensor: 2 m attached PVC cable terminated with | |||

| connection to controller. |

|

| |

|

| |||

Operating Conditions | Controller and sensor: | |||

|

| |||

Vibration and | All models meet Mil. Std. 202F requirements. Method 201A Vibration: 10 to 60Hz max., double | |||

Mechanical Shock | amplitude 0.06” (maximum acceleration 10G). Method 213B conditions H & I (Shock: 75G with unit | |||

operating; 100G for | ||||

| ||||

| duration, half sine wave. |

|

| |

|

| |||

Application Notes | Discrete: The | |||

| The sensing window size is set using DIP switches #2 and #3. The sensing distance set point is | |||

| centered within the sensing widow. The size of the sensing window may be adjusted at any | |||

| time, with or without power applied, and without | |||

| The controller has | |||

| setting if power is removed and later reapplied. | |||

| The sensing distance set point may be programmed using the Remote TEACH input | |||

| (see hookup diagrams). |

| ||

| Acceptable target angle is within ±5° of normal for a smooth, flat target; target rotation does | |||

| affect the apparent target location with respect to the sensor. | |||

| Analog: The controller has | |||

| setting if power is removed and later reapplied. | |||

| The sensing distance set point may be programmed using the Remote TEACH input | |||

| (see hookup diagrams). Acceptable target angle is within ±5° of normal for a smooth, flat target; | |||

| target rotation does affect the apparent target location with respect to the sensor. | |||

|

|

|

| |

Certifications |

|

|

| |

|

|

|

| |

Hookup Diagrams | MI17 (p. 536) |

|

| |

|

|

|

| |

LIGHT ULTRASONIC MEASURING LIGHT TEMPERATURE RADAR GAUGINGSCREENS

More information online at bannerengineering.com | 283 |