MEASUREMENT & INSPECTION

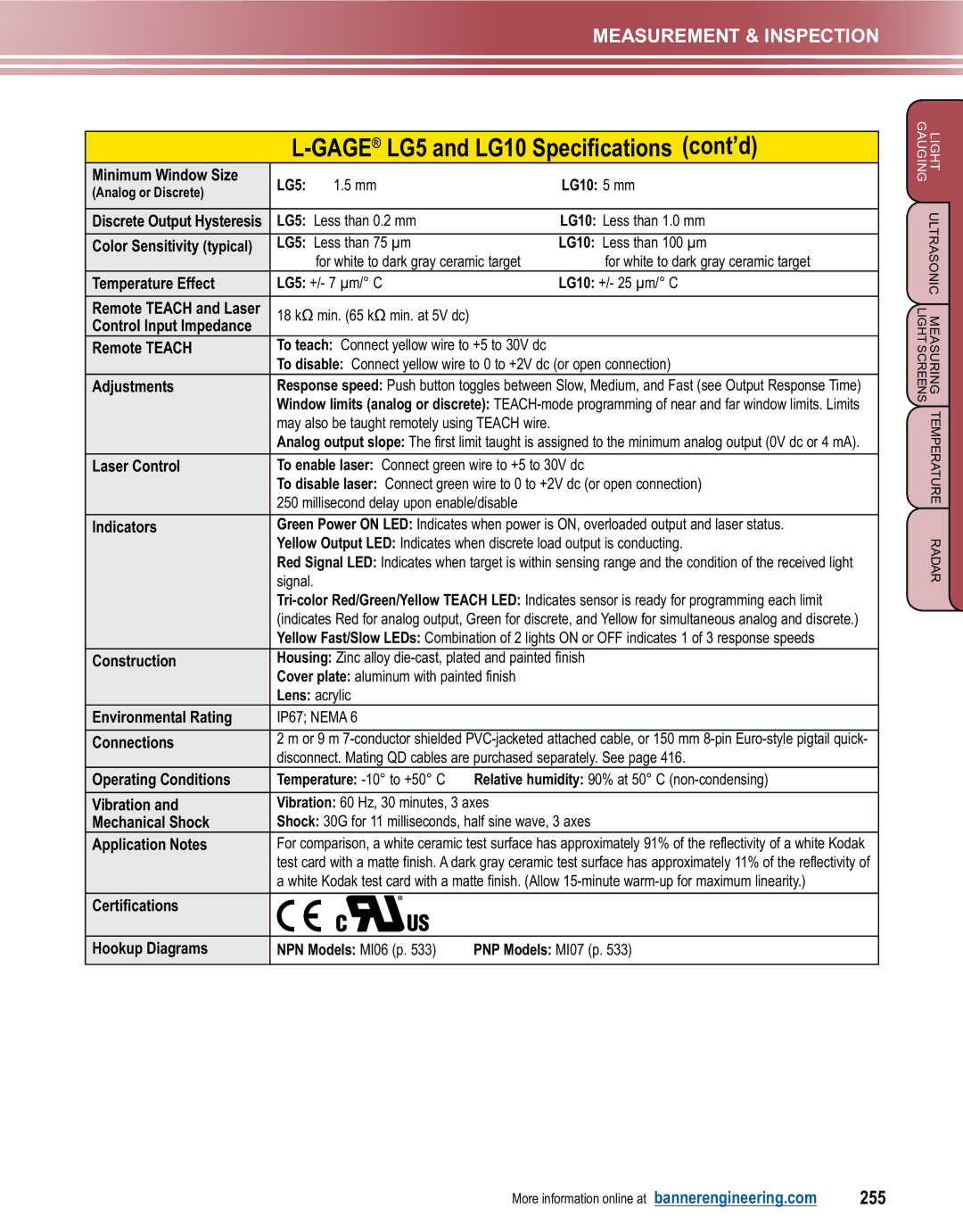

L-GAGE® LG5 and LG10 Specifications (cont’d)

Minimum Window Size | LG5: | 1.5 mm |

| LG10: 5 mm |

(Analog or Discrete) |

| |||

|

|

|

| |

|

|

|

| |

Discrete Output Hysteresis | LG5: Less than 0.2 mm |

| LG10: Less than 1.0 mm | |

|

|

|

| |

Color Sensitivity (typical) | LG5: Less than 75 µm |

| LG10: Less than 100 µm | |

|

| for white to dark gray ceramic target | for white to dark gray ceramic target | |

Temperature Effect | LG5: +/- 7 µm/° C |

| LG10: +/- 25 µm/° C | |

|

|

|

|

|

Remote TEACH and Laser | 18 kΩ min. (65 kΩ min. at 5V dc) |

|

| |

Control Input Impedance |

|

| ||

|

|

|

| |

Remote TEACH | To teach: Connect yellow wire to +5 to 30V dc |

| ||

| To disable: Connect yellow wire to 0 to +2V dc (or open connection) | |||

Adjustments | Response speed: Push button toggles between Slow, Medium, and Fast (see Output Response Time) | |||

| Window limits (analog or | |||

| may also be taught remotely using TEACH wire. |

| ||

| Analog output slope: The first limit taught is assigned to the minimum analog output (0V dc or 4 mA). | |||

|

| |||

Laser Control | To enable laser: Connect green wire to +5 to 30V dc | |||

| To disable laser: Connect green wire to 0 to +2V dc (or open connection) | |||

| 250 millisecond delay upon enable/disable |

| ||

|

| |||

Indicators | Green Power ON LED: Indicates when power is ON, overloaded output and laser status. | |||

| Yellow Output LED: Indicates when discrete load output is conducting. | |||

| Red Signal LED: Indicates when target is within sensing range and the condition of the received light | |||

| signal. |

|

|

|

| ||||

| (indicates Red for analog output, Green for discrete, and Yellow for simultaneous analog and discrete.) | |||

| Yellow Fast/Slow LEDs: Combination of 2 lights ON or OFF indicates 1 of 3 response speeds | |||

Construction | Housing: Zinc alloy | |||

| Cover plate: aluminum with painted finish |

| ||

| Lens: acrylic |

|

| |

Environmental Rating | IP67; NEMA 6 |

|

| |

|

| |||

Connections | 2 m or 9 m | |||

| disconnect. Mating QD cables are purchased separately. See page 416. | |||

Operating Conditions | Temperature: | Relative humidity: 90% at 50° C | ||

|

|

| ||

Vibration and | Vibration: 60 Hz, 30 minutes, 3 axes |

| ||

Mechanical Shock | Shock: 30G for 11 milliseconds, half sine wave, 3 axes | |||

Application Notes | For comparison, a white ceramic test surface has approximately 91% of the reflectivity of a white Kodak | |||

| test card with a matte finish. A dark gray ceramic test surface has approximately 11% of the reflectivity of | |||

| a white Kodak test card with a matte finish. (Allow | |||

|

|

|

|

|

Certifications |

|

|

|

|

|

|

| ||

Hookup Diagrams | NPN Models: MI06 (p. 533) | PNP Models: MI07 (p. 533) | ||

|

|

|

|

|

LIGHT ULTRASONIC MEASURING TEMPERATURE RADAR

GAUGINGLIGHT SCREENS

More information online at bannerengineering.com | 255 |