![]() BM 2610025580

BM 2610025580

Saw Operations

Chop Cut

Making a Chop Cut

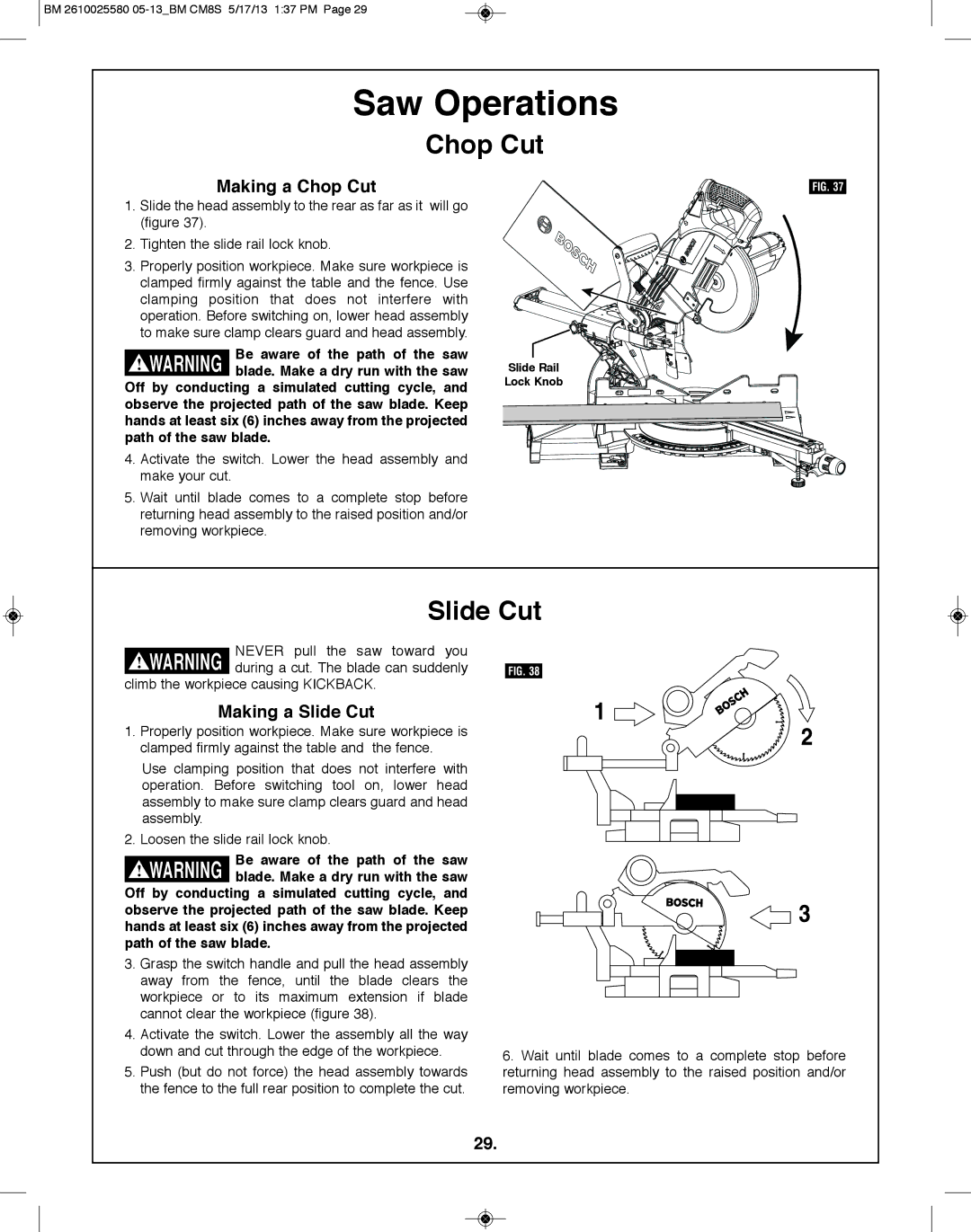

1.Slide the head assembly to the rear as far as it will go (figure 37).

2.Tighten the slide rail lock knob.

3.Properly position workpiece. Make sure workpiece is clamped firmly against the table and the fence. Use clamping position that does not interfere with operation. Before switching on, lower head assembly to make sure clamp clears guard and head assembly.

Be aware of the path of the saw ! WARNING blade. Make a dry run with the saw

Off by conducting a simulated cutting cycle, and observe the projected path of the saw blade. Keep hands at least six (6) inches away from the projected path of the saw blade.

4. Activate the switch. Lower the head assembly and make your cut.

5. Wait until blade comes to a complete stop before returning head assembly to the raised position and/or removing workpiece.

FIG. 37

Slide Rail

lock Knob

Slide Cut

NEVER pull the saw toward you during a cut. The blade can suddenly

climb the workpiece causing KICKBACK.

Making a Slide Cut

1.Properly position workpiece. Make sure workpiece is clamped firmly against the table and the fence.

Use clamping position that does not interfere with operation. Before switching tool on, lower head assembly to make sure clamp clears guard and head assembly.

2. Loosen the slide rail lock knob.

Be aware of the path of the saw ! WARNING blade. Make a dry run with the saw

Off by conducting a simulated cutting cycle, and observe the projected path of the saw blade. Keep hands at least six (6) inches away from the projected path of the saw blade.

3. Grasp the switch handle and pull the head assembly away from the fence, until the blade clears the workpiece or to its maximum extension if blade cannot clear the workpiece (figure 38).

4. Activate the switch. Lower the assembly all the way down and cut through the edge of the workpiece.

5. Push (but do not force) the head assembly towards the fence to the full rear position to complete the cut.

FIG. 38

6.Wait until blade comes to a complete stop before returning head assembly to the raised position and/or removing workpiece.

29.