![]() BM 2610025580

BM 2610025580

Adjustments

Kerf Insert

! WARNING | To avoid | possible | injury, | FIG. 15 |

disconnect | plug from | power |

|

source before performing any assembly, adjustment or repair.

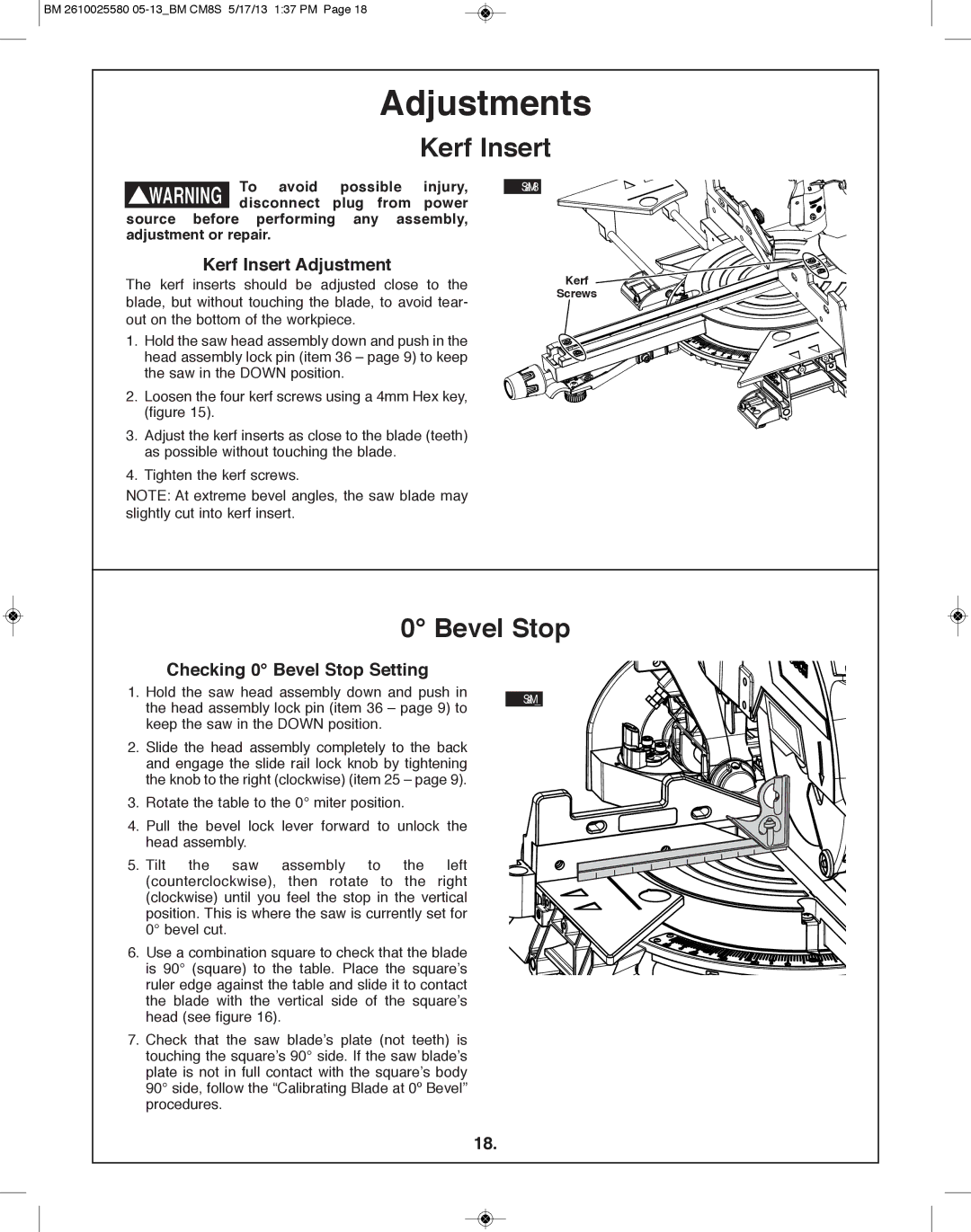

Kerf Insert Adjustment

The kerf inserts should be adjusted close to the blade, but without touching the blade, to avoid tear- out on the bottom of the workpiece.

1. Hold the saw head assembly down and push in the head assembly lock pin (item 36 – page 9) to keep the saw in the DOWN position.

2. Loosen the four kerf screws using a 4mm Hex key, (figure 15).

3.Adjust the kerf inserts as close to the blade (teeth) as possible without touching the blade.

4.Tighten the kerf screws.

NOTE: At extreme bevel angles, the saw blade may slightly cut into kerf insert.

Kerf ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Screws

Screws ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

0° Bevel Stop

| Checking 0° Bevel Stop Setting |

|

1. | Hold the saw head assembly down and push in | FIG. 16 |

| the head assembly lock pin (item 36 – page 9) to | |

|

| |

| keep the saw in the DOWN position. |

|

2. | Slide the head assembly completely to the back |

|

| and engage the slide rail lock knob by tightening |

|

| the knob to the right (clockwise) (item 25 – page 9). |

|

3. | Rotate the table to the 0° miter position. |

|

4. | Pull the bevel lock lever forward to unlock the |

|

| head assembly. |

|

5. | Tilt the saw assembly to the left |

|

| (counterclockwise), then rotate to the right |

|

| (clockwise) until you feel the stop in the vertical |

|

| position. This is where the saw is currently set for |

|

| 0° bevel cut. |

|

6. | Use a combination square to check that the blade |

|

| is 90° (square) to the table. Place the square’s |

|

| ruler edge against the table and slide it to contact |

|

| the blade with the vertical side of the square’s |

|

| head (see figure 16). |

|

7.Check that the saw blade’s plate (not teeth) is touching the square’s 90° side. If the saw blade’s plate is not in full contact with the square’s body 90° side, follow the “Calibrating Blade at 0º Bevel” procedures.

18.