![]() BM 2610025580

BM 2610025580

Adjustments

Depth of Cut

To avoid possible injury, ! WARNING disconnect plug from power

source before performing any assembly, adjustments or repairs.

When a new blade is installed, it may be necessary to check the clearance of the blade to the turntable structure. The depth stop plate is a feature provided to allow for (normal)

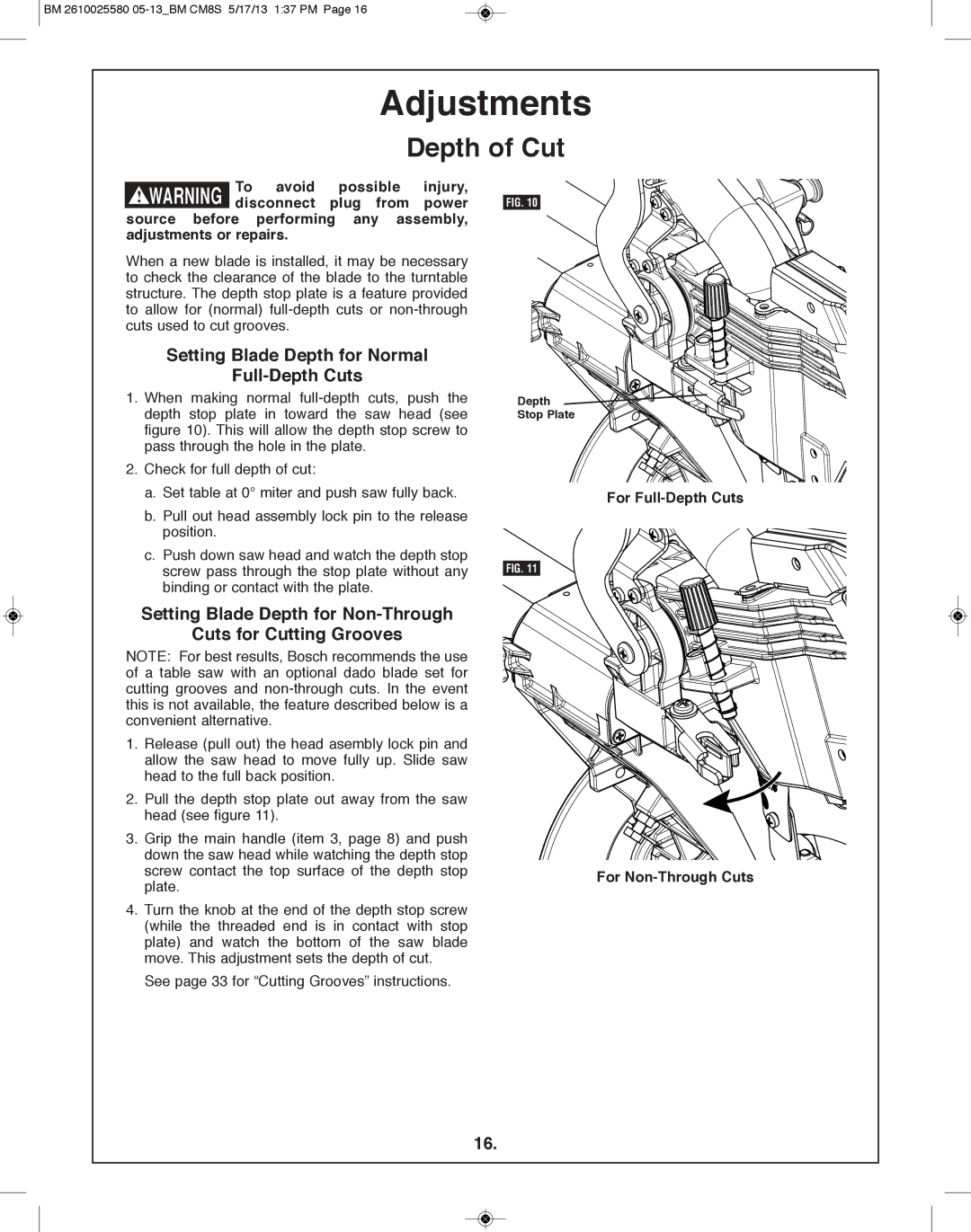

Setting Blade Depth for Normal

full-Depth Cuts

1.When making normal

2.Check for full depth of cut:

a.Set table at 0° miter and push saw fully back.

b.Pull out head assembly lock pin to the release position.

c.Push down saw head and watch the depth stop screw pass through the stop plate without any binding or contact with the plate.

Setting Blade Depth for

Cuts for Cutting Grooves

NOTE: For best results, Bosch recommends the use of a table saw with an optional dado blade set for cutting grooves and

1.Release (pull out) the head asembly lock pin and allow the saw head to move fully up. Slide saw head to the full back position.

2.Pull the depth stop plate out away from the saw head (see figure 11).

3.Grip the main handle (item 3, page 8) and push down the saw head while watching the depth stop screw contact the top surface of the depth stop plate.

4.Turn the knob at the end of the depth stop screw (while the threaded end is in contact with stop plate) and watch the bottom of the saw blade move. This adjustment sets the depth of cut.

See page 33 for “Cutting Grooves” instructions.

FIG. 10

Depth

Stop plate

for full-Depth Cuts

FIG. 11

for Non-Through Cuts

16.