![]() BM 2610025580

BM 2610025580

Saw Operations

Miter Cuts

What’s a Miter Cut – Saw features

•A “miter cut” is a

•Miter cuts can be made at any angle across a workpiece within this saw’s range, from 52° left to 60° right.

•The miter scale shows the angle of the blade relative to the saw’s fence. The miter pointer is attached to the table and indicates the saw’s miter position before the cut is made.

•Ten positive miter detents are provided for fast and accurate preset miter angles – locations are at 45°, 31.6°, 22.5°, 15° left and right, and center at 0°. The right side has an additional miter detent of 60°.

•The crown molding detents on the left and right are at 31.6° for compound cutting 38° “spring angle” crown molding lying flat on the table (see Cutting Crown Molding on page 36).

•For precision settings at miter angles very close to the miter detents, use the miter detent override to prevent the detent from automatically engaging the detent slot. See detent override instructions on page 28.

•A miter cut can be made either as a chop cut or

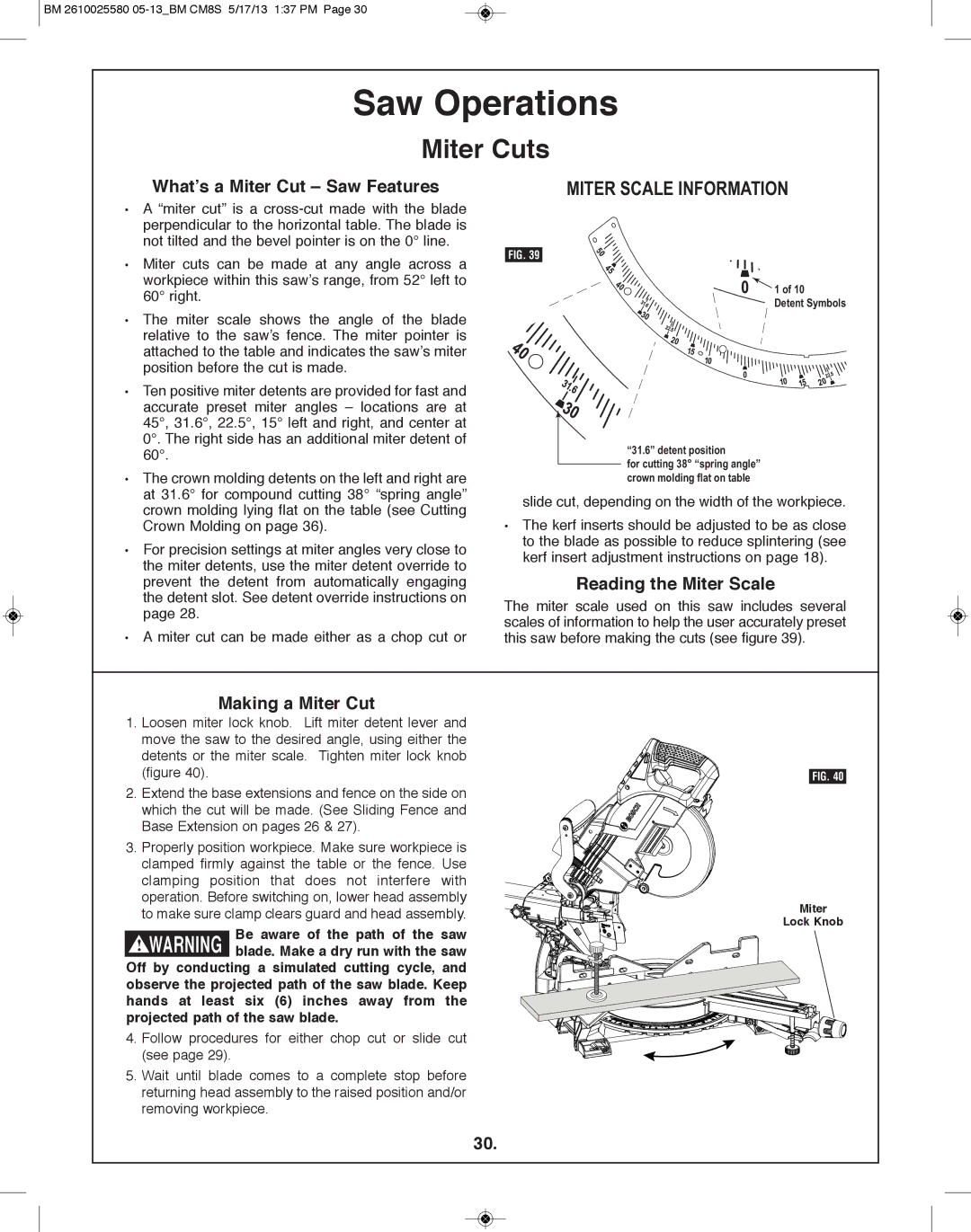

MITER SCALE INFORMATION

FIG. 39

![]()

![]() 1 of 10

1 of 10

Detent Symbols

“31.6” detent position

for cutting 38° “spring angle” crown molding flat on table

slide cut, depending on the width of the workpiece.

•The kerf inserts should be adjusted to be as close to the blade as possible to reduce splintering (see kerf insert adjustment instructions on page 18).

Reading the Miter Scale

The miter scale used on this saw includes several scales of information to help the user accurately preset this saw before making the cuts (see figure 39).

Making a Miter Cut

1.Loosen miter lock knob. Lift miter detent lever and move the saw to the desired angle, using either the detents or the miter scale. Tighten miter lock knob (figure 40).

2.Extend the base extensions and fence on the side on which the cut will be made. (See Sliding Fence and Base Extension on pages 26 & 27).

3.Properly position workpiece. Make sure workpiece is clamped firmly against the table or the fence. Use clamping position that does not interfere with operation. Before switching on, lower head assembly to make sure clamp clears guard and head assembly.

Be aware of the path of the saw blade. Make a dry run with the saw Off by conducting a simulated cutting cycle, and

observe the projected path of the saw blade. Keep hands at least six (6) inches away from the projected path of the saw blade.

4.Follow procedures for either chop cut or slide cut (see page 29).

5.Wait until blade comes to a complete stop before returning head assembly to the raised position and/or removing workpiece.

FIG. 40

Miter

lock Knob

30.