![]() BM 2610025580

BM 2610025580

Adjustments

0° Bevel Stop (continued)

! WARNING | Disconnect plug from power | FIG. 17 |

source before performing any | ||

|

|

assembly, adjustment or repair to avoid possible injury.

NOTE: Your miter saw was completely adjusted at the factory. However, during shipment, slight misalignment may have occurred. Check the following settings and adjust if necessary prior to using this miter saw.

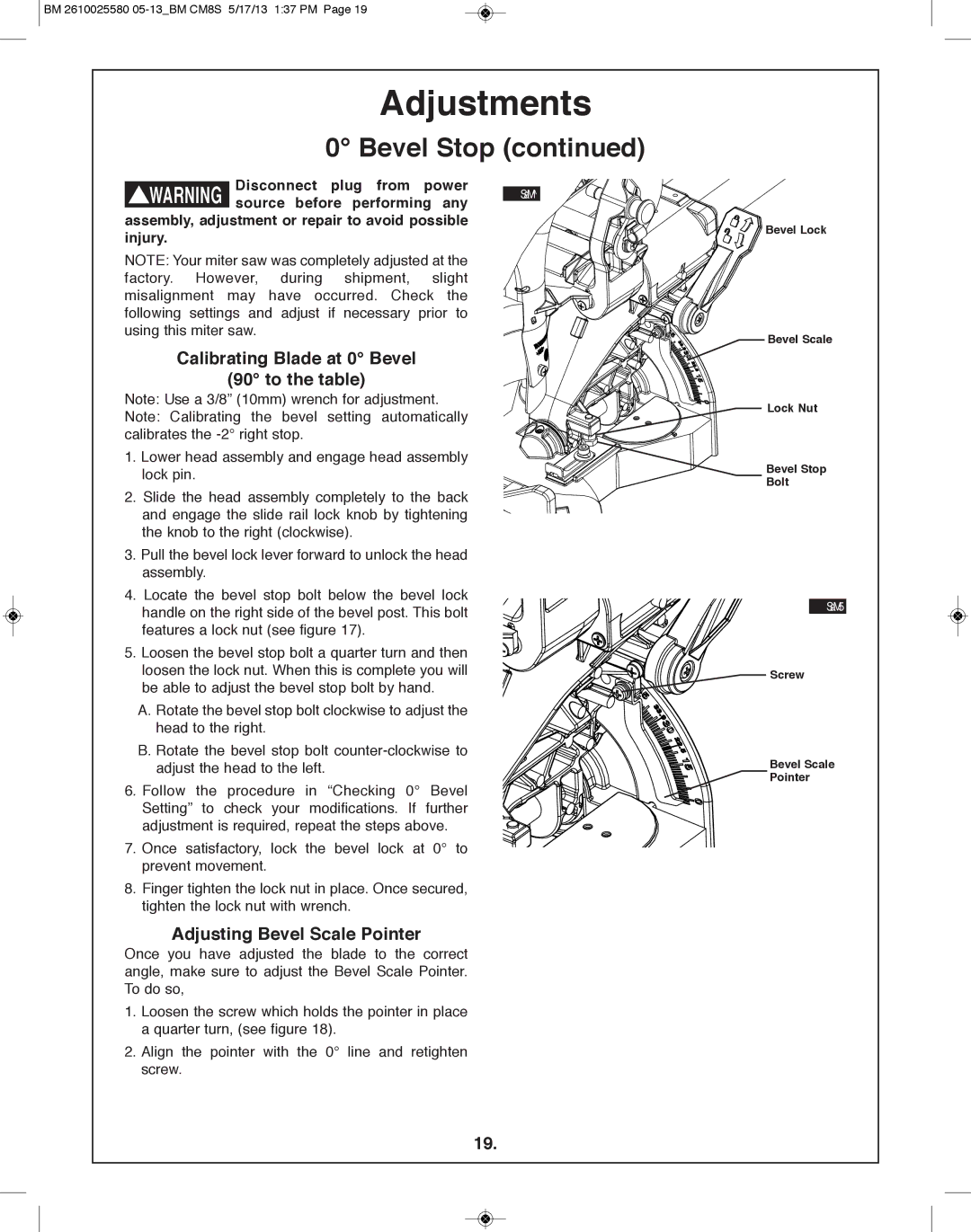

Calibrating Blade at 0° Bevel

(90° to the table)

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Bevel lock

Bevel lock

![]() Bevel Scale

Bevel Scale

Note: Use a 3/8” (10mm) wrench for adjustment. | lock Nut | |

Note: Calibrating the bevel setting automatically | ||

| ||

calibrates the |

| |

1. Lower head assembly and engage head assembly | Bevel Stop | |

lock pin. | ||

Bolt | ||

|

2. Slide the head assembly completely to the back and engage the slide rail lock knob by tightening the knob to the right (clockwise).

3.Pull the bevel lock lever forward to unlock the head assembly.

4. Locate the bevel stop bolt below the bevel lock | FIG. 18 | |

handle on the right side of the bevel post. This bolt | ||

| ||

features a lock nut (see figure 17). |

| |

5. Loosen the bevel stop bolt a quarter turn and then |

| |

loosen the lock nut. When this is complete you will | Screw | |

be able to adjust the bevel stop bolt by hand. | ||

| ||

A. Rotate the bevel stop bolt clockwise to adjust the |

| |

head to the right. |

| |

B. Rotate the bevel stop bolt | Bevel Scale | |

adjust the head to the left. | ||

pointer | ||

|

6. Follow the procedure in “Checking 0° Bevel Setting” to check your modifications. If further adjustment is required, repeat the steps above.

7. Once satisfactory, lock the bevel lock at 0° to prevent movement.

8.Finger tighten the lock nut in place. Once secured, tighten the lock nut with wrench.

Adjusting Bevel Scale pointer

Once you have adjusted the blade to the correct angle, make sure to adjust the Bevel Scale Pointer. To do so,

1.Loosen the screw which holds the pointer in place a quarter turn, (see figure 18).

2.Align the pointer with the 0° line and retighten screw.

19.