![]() BM 2610025580

BM 2610025580

Saw Operations

Special Cuts

Cutting bowed material and round material are only two examples of special cuts.

Use clamping position that does not interfere with operation.

Before switching on, lower head assembly to make sure clamp clears guard and head assembly.

Be aware of the path of the saw ! WARNING blade. Make a dry run with the

saw Off by conducting a simulated cutting cycle, and observe the projected path of the saw blade. Keep hands at least six (6) inches away from the projected path of the saw blade.

To provide sufficient (minimum ! WARNING 6") spacing from hand to saw

blade, extend the sliding fence and base extensions when making extreme bevel, miter or compound cuts.

Cutting Bowed Material

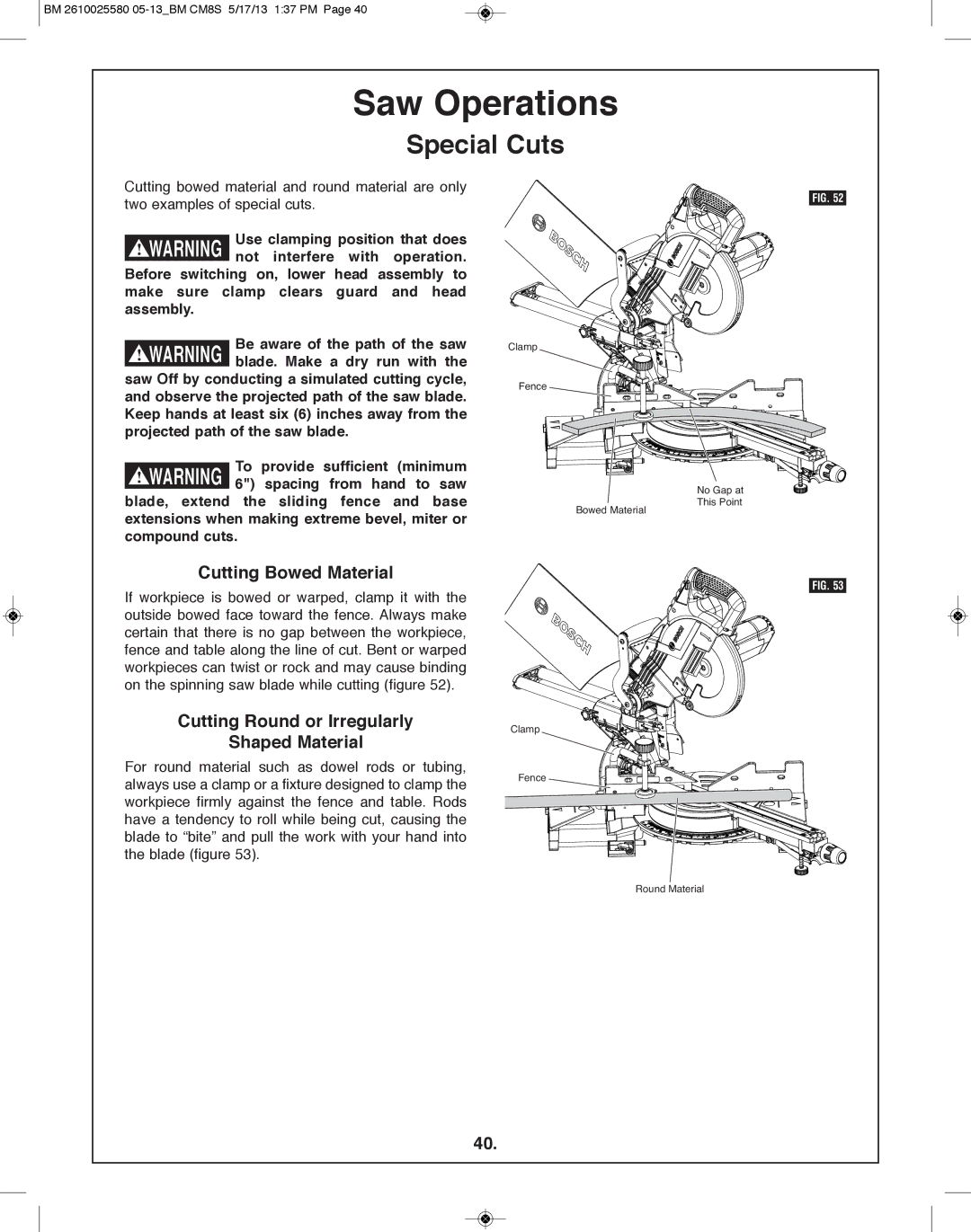

If workpiece is bowed or warped, clamp it with the outside bowed face toward the fence. Always make certain that there is no gap between the workpiece, fence and table along the line of cut. Bent or warped workpieces can twist or rock and may cause binding on the spinning saw blade while cutting (figure 52).

Cutting Round or Irregularly

Shaped Material

For round material such as dowel rods or tubing, always use a clamp or a fixture designed to clamp the workpiece firmly against the fence and table. Rods have a tendency to roll while being cut, causing the blade to “bite” and pull the work with your hand into the blade (figure 53).

FIG. 52

Clamp

Fence

| No Gap at |

Bowed Material | This Point |

|

FIG. 53

Clamp

Fence

Round Material

40.