![]() BM 2610025580

BM 2610025580

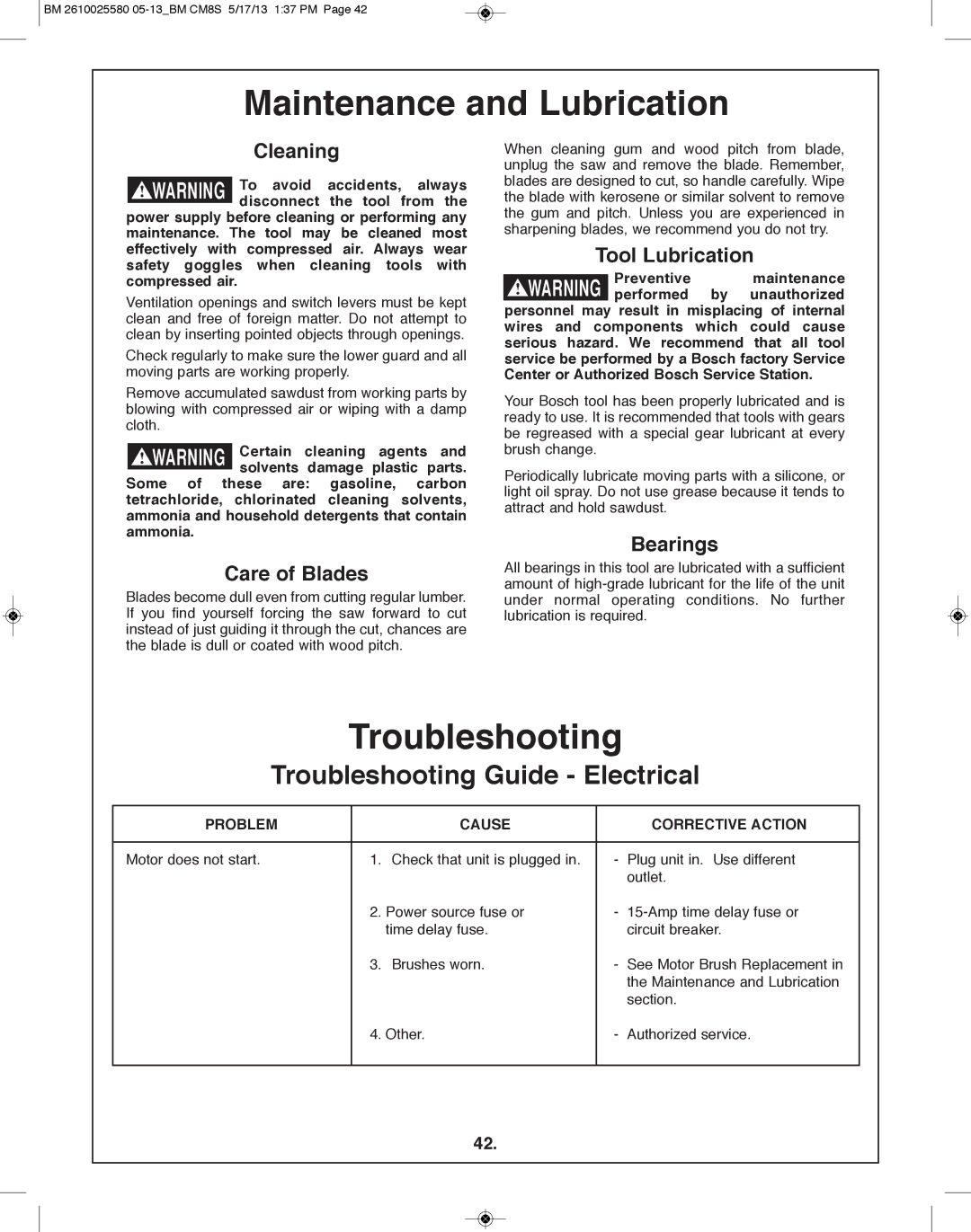

Maintenance and lubrication

Cleaning

!WARNING To avoid accidents, always disconnect the tool from the

power supply before cleaning or performing any maintenance. The tool may be cleaned most effectively with compressed air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

Check regularly to make sure the lower guard and all moving parts are working properly.

Remove accumulated sawdust from working parts by blowing with compressed air or wiping with a damp cloth.

!WARNING Certain cleaning agents and solvents damage plastic parts.

Some of these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

Care of Blades

Blades become dull even from cutting regular lumber. If you find yourself forcing the saw forward to cut instead of just guiding it through the cut, chances are the blade is dull or coated with wood pitch.

When cleaning gum and wood pitch from blade, unplug the saw and remove the blade. Remember, blades are designed to cut, so handle carefully. Wipe the blade with kerosene or similar solvent to remove the gum and pitch. Unless you are experienced in sharpening blades, we recommend you do not try.

Tool lubrication

preventive maintenance

!WARNING performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch factory Service Center or Authorized Bosch Service Station.

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

Periodically lubricate moving parts with a silicone, or light oil spray. Do not use grease because it tends to attract and hold sawdust.

Bearings

All bearings in this tool are lubricated with a sufficient amount of

Troubleshooting

Troubleshooting Guide - Electrical

pROBlEM |

| CAUSE |

| CORRECTIVE ACTION |

|

|

|

|

|

Motor does not start. | 1. | Check that unit is plugged in. | - | Plug unit in. Use different |

|

|

|

| outlet. |

| 2. Power source fuse or | - | ||

|

| time delay fuse. |

| circuit breaker. |

| 3. | Brushes worn. | - | See Motor Brush Replacement in |

|

|

|

| the Maintenance and Lubrication |

|

|

|

| section. |

| 4. | Other. | - | Authorized service. |

|

|

|

|

|

42.