Product Code

Page

Introduction

Important Safety Instructions

For repair or adjustment

For Users in the UK, EIRE, Malta and Cyprus only

Page

Contents

Embroidering

Using the Memory Function

Care and Maintenance

Troubleshooting

USB port

Machine Features

Included accessories

Accessories

Following are available as optional accessories

Optional accessories

Front view

Names of Machine Parts and Their Functions

Right-side/rear view

Needle and embroidery foot section

Start/stop button

Operation buttons

LCD liquid crystal display touch panel

Operation panel

Page

Getting Ready

Basic Steps for Embroidering

Turning the Machine On/Off

Power supply precautions

Turning off the machine

CUnplug the power supply cord from the electrical outlet

DUnplugjack. the power cord from the power supply

Turning on the machine

AMake sure that the machine is turned off

Embroidery unit precautions

Attaching the Embroidery Unit

Attaching the embroidery unit

Carriage moves to its initial position

CTurn on the machine

Confirmation message is displayed

CTurn off the machine

Removing the embroidery unit

ARemove the embroidery frame

BPress , and then press

Moves the embroidery unit carriage to its storage position

LCD Liquid Crystal Display Operation

Viewing the LCD

Pattern type selection

Changing the machine settings

CPress the item to be set

BPresspanel. Settings key on the operation

DWhen settings are complete, press Back key

ATurn on the machine

CPress the item to be displayed

Checking machine operating procedures

DPressnext page. Next page key to switch to

BPresspanel. Help key on the operation

Preparing Items for Embroidering

Checking the needle

Needle precautions

Preparing the Needle

DLower the presser foot lever

Replacing the needle

This model Other model

Winding/Installing the Bobbin

Bobbin precautions

Winding the bobbin

Use the embroidery bobbin thread for embroidering

Start/stop button lights up in orange

Make sure that the thread passes under the pretension disk

Bobbin winding will stop

LPress Start/stop button once

Start/stop button immediately to stop the bobbin winding

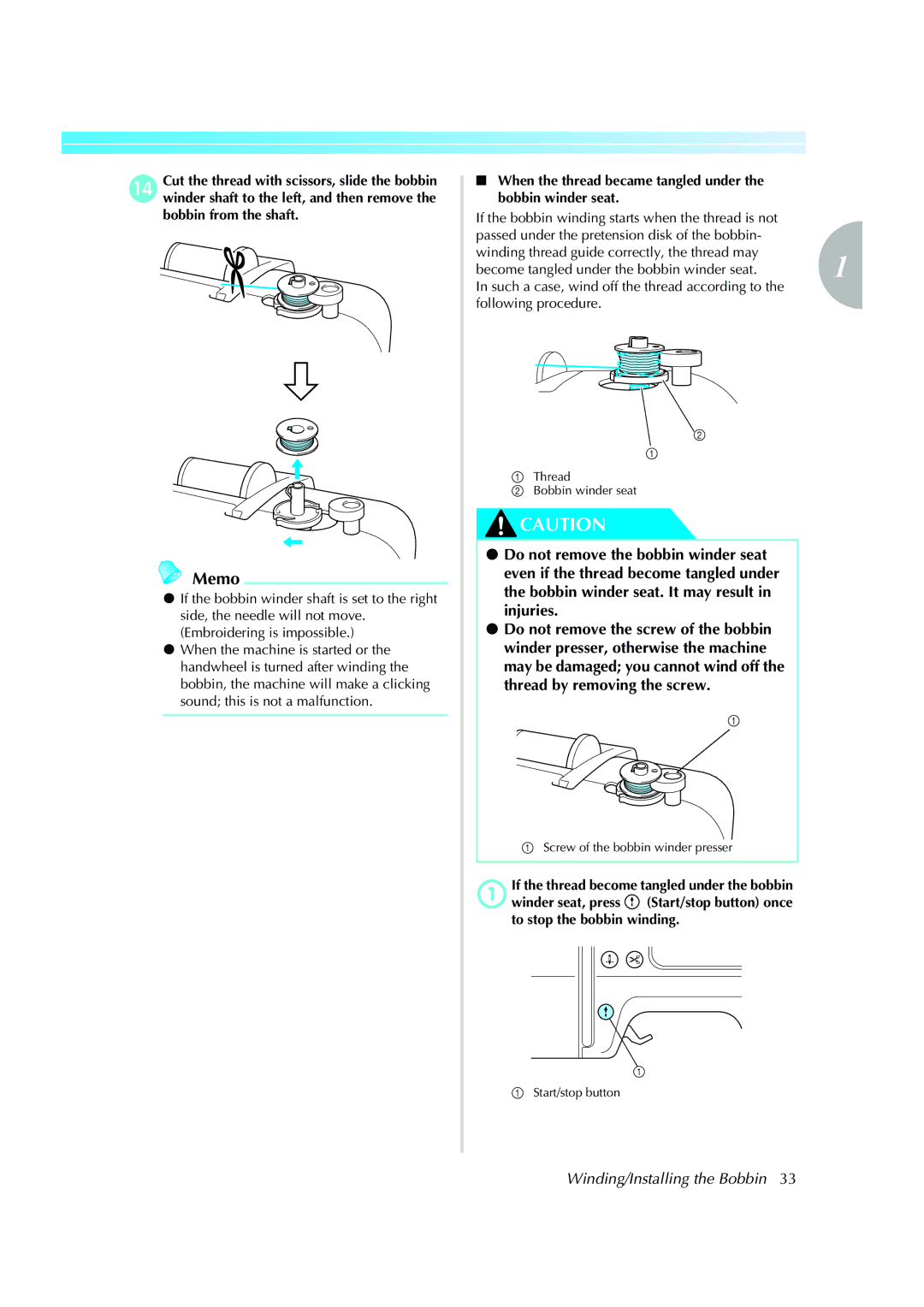

When the thread became tangled under the bobbin winder seat

This model

Installing the bobbin

Install the bobbin wound with thread

Actual size

Cutter cuts the thread

Bobbin cover opens

Be careful not to drop the bobbin

Be sure to insert the bobbin correctly

Reattach the bobbin cover

Information about the spools of thread is described below

Upper Threading

About the spool of thread

Embroidery foot is raised

Threading the upper thread

ATurn on the machine BRaise the presser foot lever

Hand as shown below

Thread take-up lever

Upper threading is finished

Such a case, start from m again

Getting Ready

Material to the fabric

Preparing the Fabric

Attaching a stabilizer

Embroidery frame large option

Setting the fabric in the embroidery frame

Embroidery frame medium

Embroidery frame small option

Medium Option Embroidery sheet large option

Embroidery sheet

For details, refer to

BPlace the embroidery sheet on the inner frame

Abobbin and set it into the bobbin case

Attaching the Embroidery Frame

Attaching the embroidery frame

ARaise the presser foot lever

Removing the embroidery frame

Embroidery

Embroidery pattern types

Selecting Embroidery Patterns

Copyright information

† Setting the display while embroidering

Setting for embroidering

LCD button Example Selecting alphanumeric characters

Specify the characters for embroidery

Selecting alphanumeric characters

Example Selecting an embroidery pattern

Select the pattern

Selecting an embroidery pattern

APress

Select the stitch

Using an embroidery card

Selecting a frame pattern

Select the frame shape

Operation is the same as in Selecting an embroidery pattern

CTurn on the machine DPress On the screen

ESelect a pattern

BSet the embroidery thread, and thread the needle

Embroidering

Embroidering a pattern

Prepareon the screen.embroidery thread of the color shown c

Needle is raised and the threads are cut

EPress Start/stop button

HPress Start/stop button again

Press Thread cutter button once

ASelect an appliqué pattern

Appliquéing

KRemove the upper thread

MCut the excess thread

Position for the appliqué is stitched, and the machine stops

Editing and Saving Patterns

Adjusting the layout and the size

Rotation key

Size key

Change position keys

Layout key

Adjusting the upper thread tension

Bobbin thread appears slightly on the right side of fabric

Adjusting the bobbin thread tension

Bobbin thread is too tight

Bobbin thread is too loose

Enter DEF and press Press KPress to turn it to

Connecting character patterns

Stitching starting point is set to lower left of the design

APressmachine. Start/stop button to stop

Resewing

Forward one stitch increases the stitch number

Thread runs out partway through a design

Stopping while embroidering

ASet the upper thread or bobbin thread Press

KRestart the embroidery

Always remove the embroidery unit when you move the machine

ETurn off the machine

FTurnpattern.on the machine, and then select

Tajima .dst Embroidery Data

Using the Memory Function

Embroidery data precautions

Precautions on Using the Computer to Create and Save Data

CPress

Switch screens using Previous page key

Saving patterns

Selected pattern is shown in reverse highlighting

Retrieving embroidery patterns from the computer

FPress

Switch screens using

GAdjust the pattern as desired, and then begin embroidering

ESelect the pattern you wish to retrieve

Appendix

FRemove the bobbin case

Care and Maintenance

Cleaning the machine surface

Cleaning the race

Do not apply oil to the bobbin case

DHold the embroidery foot Q with your right hand, as shown

This section describes how to attach the embroidery foot Q

Attaching the Embroidery Foot

Attaching the embroidery foot

Set the embroidery foot perpendicular

Embroidery foot is scratched, or

Troubleshooting

Correctly install the needle

Burr on it Service center Area around the hole

Thread is tangled

Remove the tangled thread. If

Bobbin-winding thread guide Correctly

On it

Needle is bent or blunt Replace the needle Skipped

Correctly install the needle Thread tension is incorrect

Thread tension is incorrect

Bobbin thread

No pattern selected Select a pattern

Be sure to rethread the machine. If you press

Error messages

Pressing Retrieve key

Error Message Probable Cause

An Embroidery Memory Card that may not compatible with your

When the embroidery unit is attached

Embroidery key was pressed when the embroidery unit is not

Refer to

Operation beep

Adjusting the LCD

Following screen appears

When the following screen appears, upgrading is completed

Then start the procedure again from step

Upgrading Your Machines Software

Air vent

Index

10, 31

Page

885-V51 English XE5427-001

![]() CAUTION

CAUTION![]() (Start/stop button) once to stop the bobbin winding.

(Start/stop button) once to stop the bobbin winding.