MACHINE

LUBRICATION

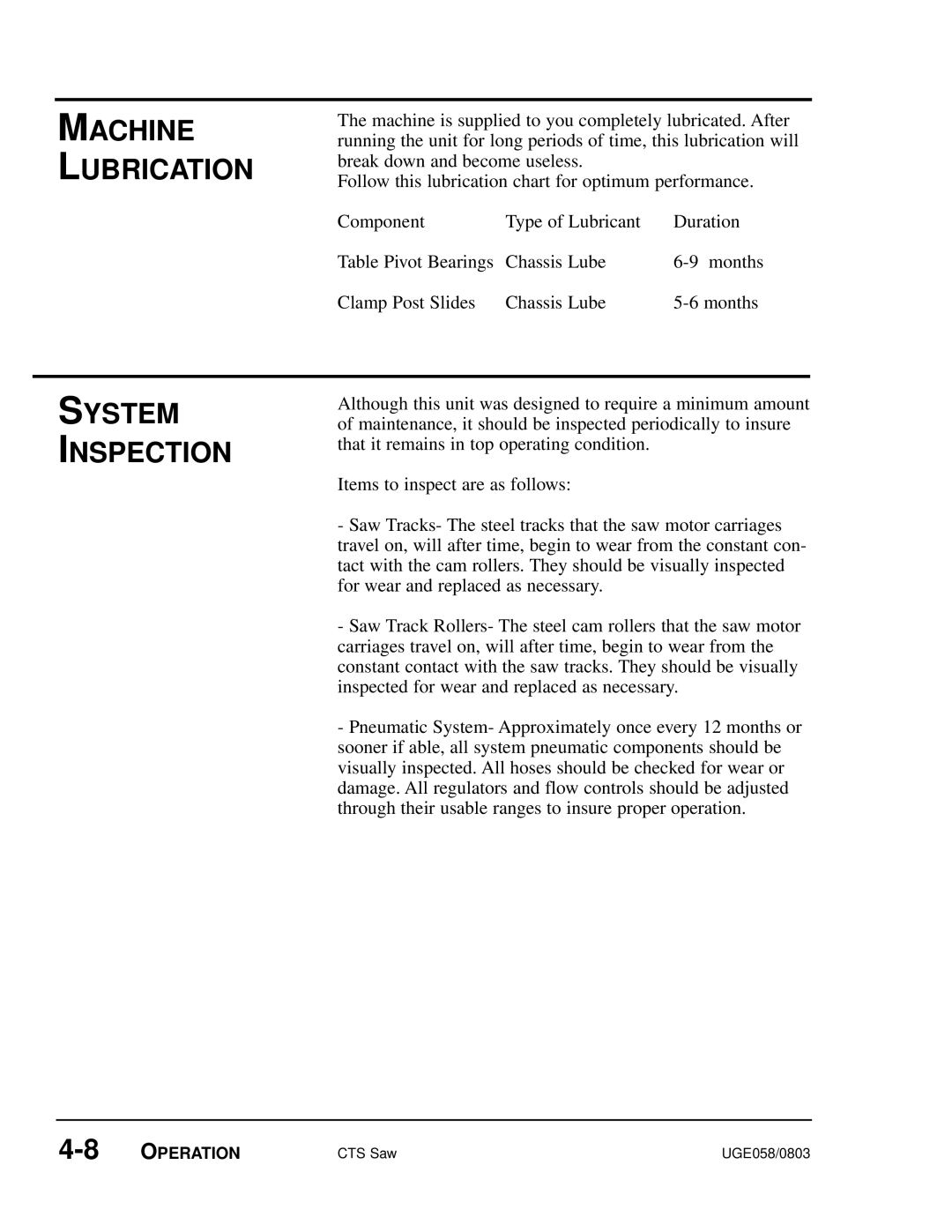

The machine is supplied to you completely lubricated. After running the unit for long periods of time, this lubrication will break down and become useless.

Follow this lubrication chart for optimum performance.

Component | Type of Lubricant | Duration |

Table Pivot Bearings | Chassis Lube | |

Clamp Post Slides | Chassis Lube |

SYSTEM

INSPECTION

Although this unit was designed to require a minimum amount of maintenance, it should be inspected periodically to insure that it remains in top operating condition.

Items to inspect are as follows:

-Saw Tracks- The steel tracks that the saw motor carriages travel on, will after time, begin to wear from the constant con- tact with the cam rollers. They should be visually inspected for wear and replaced as necessary.

-Saw Track Rollers- The steel cam rollers that the saw motor carriages travel on, will after time, begin to wear from the constant contact with the saw tracks. They should be visually inspected for wear and replaced as necessary.

-Pneumatic System- Approximately once every 12 months or sooner if able, all system pneumatic components should be visually inspected. All hoses should be checked for wear or damage. All regulators and flow controls should be adjusted through their usable ranges to insure proper operation.

CTS Saw | UGE058/0803 |