LUBRICATION

General

Remove the ignition key to prevent accidental movement during lubrication.

If lubricating with an oil can, fill the can with engine oil.

If lubricating with grease, use grease 503 98

If the Rider is used daily it should be lubricated twice a week.

Wipe off excess lubricant after lubrication.

It is important that lubricant does not get onto the drive surfaces of the belts or pulleys. If this happens, try to clean it off with white spirit. If the belt continues to slip it must be replaced. Do not use petrol or other petroleum products to clean

Lubricating wires

Lubricate both ends of the wires, moving the controls through their full travel range while doing so. Refit the rubber protectors over the wires after lubrication. Wires with a casing will seize up unless lubricated regularly. If a wire seizes it can cause operating problems, such as difficulty disengaging the differential lock.

If a wire does seize up, remove it and hang it up vertically. Lubricate with light engine oil until the oil starts to drip from the lower end. Useful hint: Fill a small plastic bag with oil, tape it tightly around the wire casing and hang the wire vertically from the bag overnight. If this does not free up the wire then it must be replaced.

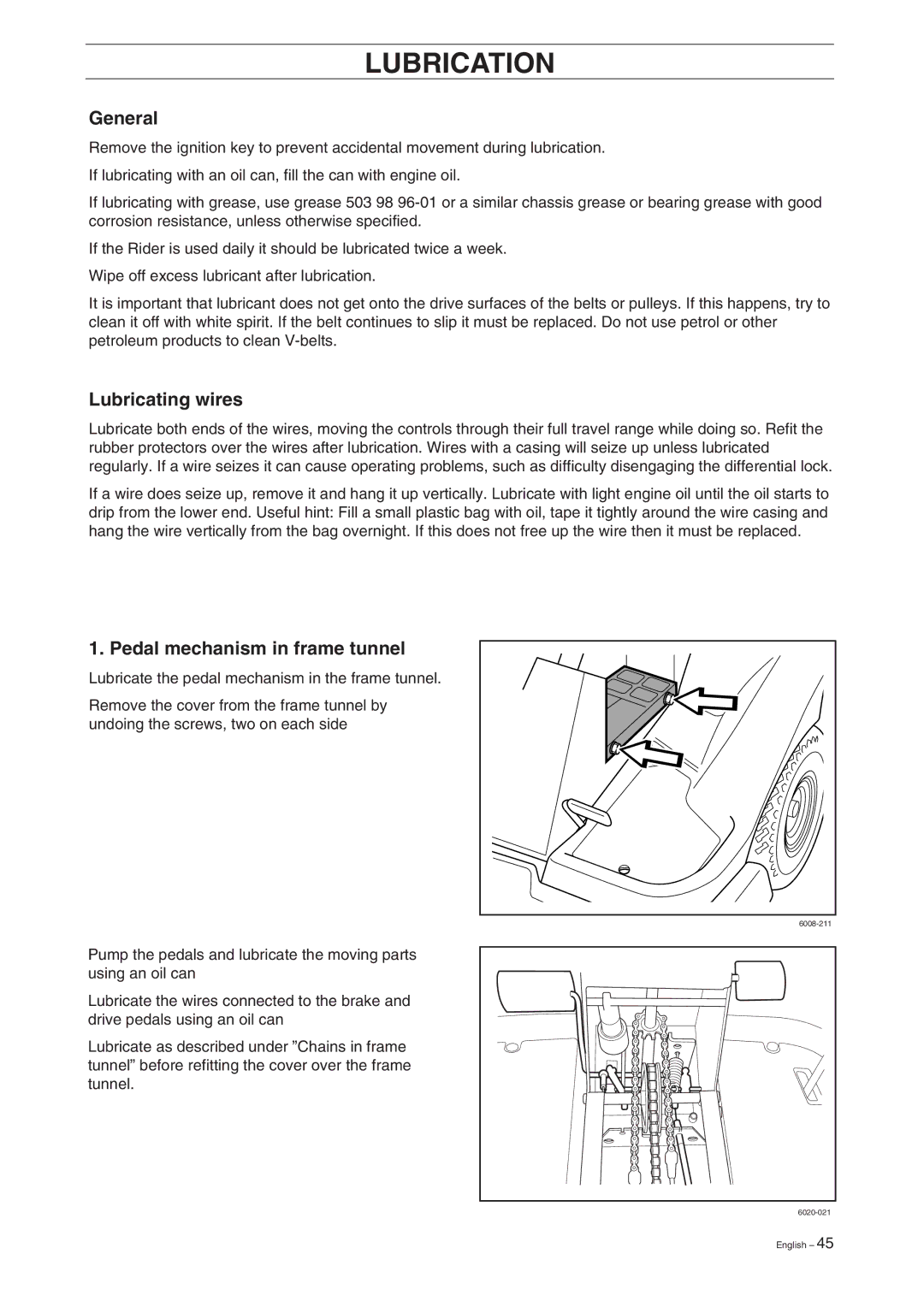

1. Pedal mechanism in frame tunnel

Lubricate the pedal mechanism in the frame tunnel.

Remove the cover from the frame tunnel by undoing the screws, two on each side

Pump the pedals and lubricate the moving parts using an oil can

Lubricate the wires connected to the brake and drive pedals using an oil can

Lubricate as described under ”Chains in frame tunnel” before refitting the cover over the frame tunnel.

English – 45 |