LUBRICATION

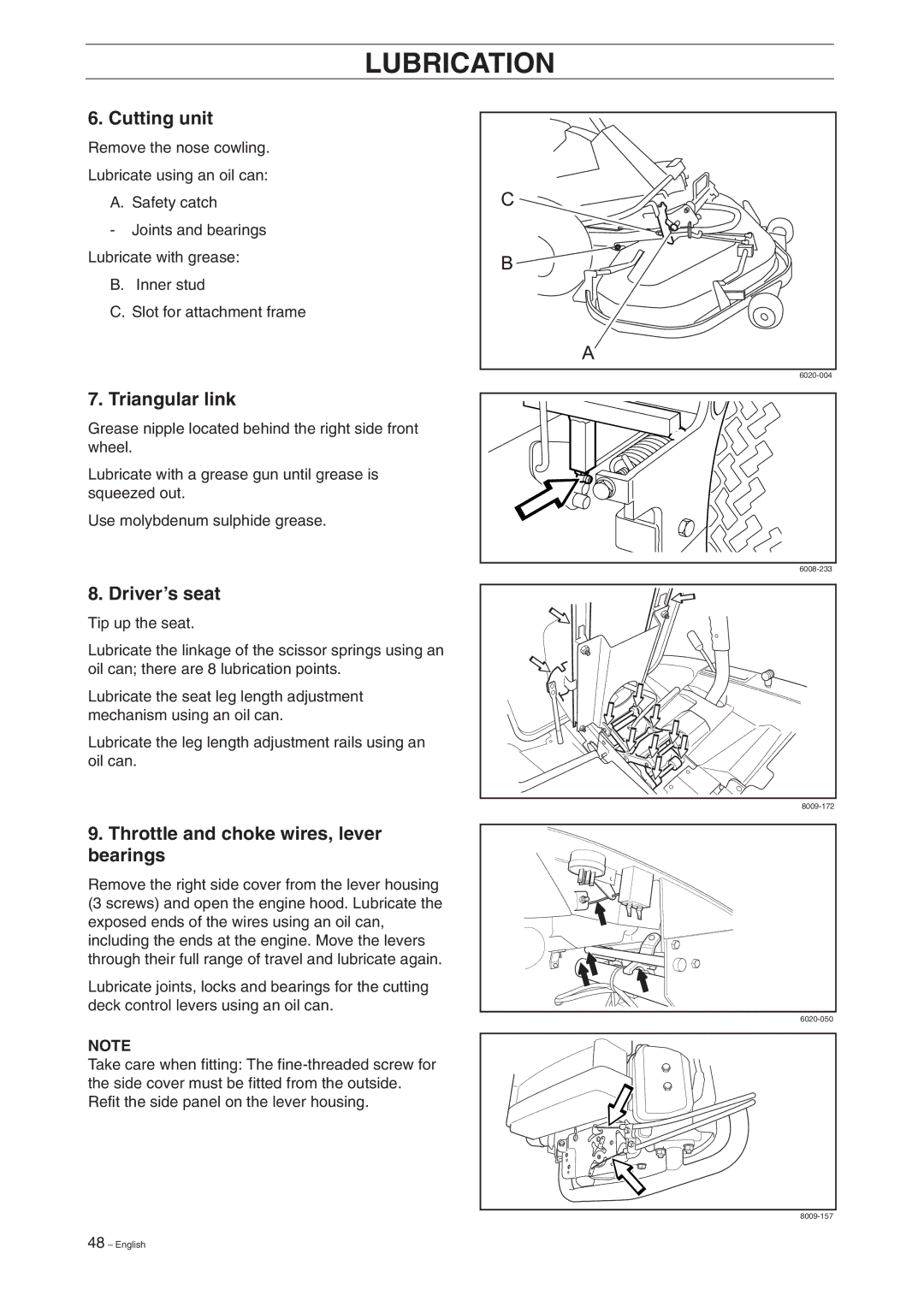

6. Cutting unit Remove the nose cowling. Lubricate using an oil can:

A. Safety catch

- Joints and bearings Lubricate with grease:

B. Inner stud

C. Slot for attachment frame

7. Triangular link

Grease nipple located behind the right side front wheel.

Lubricate with a grease gun until grease is squeezed out.

Use molybdenum sulphide grease.

8. Driver’s seat

Tip up the seat.

Lubricate the linkage of the scissor springs using an oil can; there are 8 lubrication points.

Lubricate the seat leg length adjustment mechanism using an oil can.

Lubricate the leg length adjustment rails using an oil can.

9. Throttle and choke wires, lever bearings

Remove the right side cover from the lever housing (3 screws) and open the engine hood. Lubricate the exposed ends of the wires using an oil can, including the ends at the engine. Move the levers through their full range of travel and lubricate again.

Lubricate joints, locks and bearings for the cutting deck control levers using an oil can.

NOTE

Take care when fitting: The

48 – English