Automatic Dishwashers

If ever you need us -- were available You Can Count On Us

We Service Wh,t We Sell

Sears t

Contents

Introduction

Removal and Control of Hard Water Film

WATER, Detergent and the Automatic Dishwasher

Extremely hot water

Filming

Possible Cause & Solution

Bronze Tarnish on Silverware

Black Marks on Dinnerware

Attach Screws Access Panel

Cleaningmineraldepositsfromporcelainsurfaces

Installation

Or y Branch

Drain Hose Connected to Disposer

2HOLE or Larger

Sink X,,T Left

Drain Hose Connection Through Floor

Drain Hoseconnectionto Sink Drain

Inlet Valve ,JUNCTION BOX Assembly

Cutting Access Holes

Green Ground Screw

Circuit Conductorground Wire

Electrical

GROUND1NGINSTRUCTIONS

Reen Ground Screw

Shut OFF VA LV E

HOT Wate Line

Drain

Trap P or Above

Sink AI Left Sink AT Right

HOW to POSITION, ALIGN, and LEVEL, Your Dishwasher

TWO Ways to Anchor Your Dishwasher

Wjash System

Two Level Wash Feature

Testing Water Charge Level

Switch

Ttttt

Spray Arm Assembly

Pushlodgedparticles

Three Level Wash System

Bearing Assembly

Removal of Mtddle Spray Arm

Removal of Upper Spray Arm Only

Water Inlet Valve

Side

Plunger Diaphragm

Washer Atmospheric PRESSURE£ B

Plunger Hole Line Water Pressure

Flow Washer

Sen/zcing

Testing

Curved Side Screen Sealer Washer

Metal Washer Flow Plastic Retainer

45 sec

Marking

Page

Side Water Inlet, Steam Trap and Venting

WA1ERiNLETASSEMBLY

Towaterinletvalve

Plasticnut

Motor and Pump Assembly Assembled

Inner Door

Exit Flow of Moist AIR During DRY Cycle Vent

PU M P Plate

Pump Assembly

Main Motor and Relay

Bottom of Relay

Page

Level Tower Pump 5y,srem This

System Uses Same Pump Housing aS u L

Housin With the recirculating

Osed Off For this Reason He bwer Utltz,es a. lower

Timer

Testing the Motor and Relay

Motor Main or Run Winding Check

Relaystart

Position

Motor Start Circuit Wash and Rinse Cycle

TAR. T .,..BLUE-ORANGE Timer t- Relay

Check the voltage as shown in Position C

Motor 5tart Circuit Drain Cycle

Volt Supply Motor Start Relay

115

Wash

Or Connected Directly to Terminal Block of Dishwasher

Terminal

WAs.ER

CA U T/OiM

Center Motor Shaft with Pump Housing With Service Tool

Motor nstaltation

ROD

Install Ihese Screws First TUB

No TE

Hoses and Couplers

Hose and Coupler Assembly 8 compact model

Faucet Coupler

Ring

Sleevegasket

Detergent DLpenser- B/-Metal Operated

Dispensers

Description

Fill Neck Scoop Wetting Agent Liquid

Wetting Agent Dispenser Bi-Metal Operated

Into Fill Neck

Drainsback .J Ntosupp

FIGUP,E

CAM Switch

Timers

CAM

Motor

Checking The 5-Button Swttch

Selector Switches

Sam-Wash or High Temperature Wash/Rin.se Thermostat

Thermostats and Temperature Indicators

Mylar Jacket

Checking Thermostat Operation

Figurego

Iiiiiiiii

Iii ii!ii!!i!i

4tfi Rinse

SanM4/ash Delay Circuit

DRY

Water Heat Option Hot Rinse

Sanitize Delay Light Circuit Power Sani Wash Cycle Selector

Page

FIGUREG3C

Page

Door and Float Switches

Door Latches and Switches

TCH on

FLO Switch

Cycle Charts

Example

Ester Line Charts

Fill Phase Normal Cycle

Page

First Wash Normal Cycle

Relay Switch Opens After Motor Starts

Voltage Checks

Continuity Check

One Piece Outer Door Control Panel

Door Assemblies

Two Piece Outer Door Control Panel

Anti Tilt Assembly38 Portable Models

Arm Replacement 8 Dishwashers

£RING

END CAP Rack

Racks

Upper Front Lower Rear Roller

Tub Gaskets

To Replace

Page

Cord Reel

Casters

Caster Replacement Potlable Dishwashers

Tubs

Convection Method

Drying System

Forced Air Method

Checking Blower Operadon

SeRE A sEMBL

Heating Elements

Heating Element

Operation

Eatersymbol

Heater Testing

Hot Dry Cool Dry Power Miser SWHch

Orange BUS Timer

Power Miser

Power Miser Circuits Single Pole Double Throw Switch

Heater White

Blower

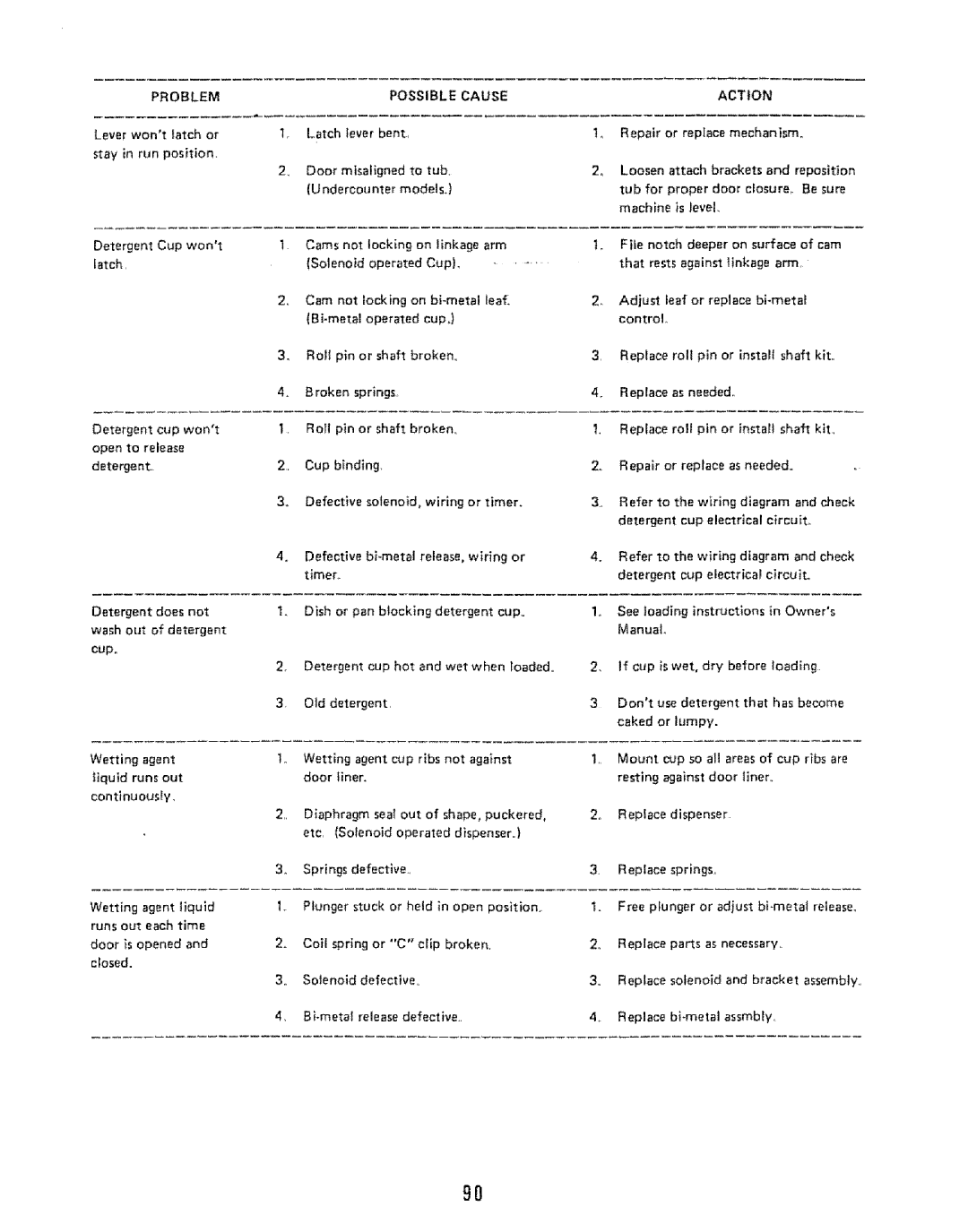

General Trouble Shooting

Trouble Shooting

Check selector switch per wiring diagram

Turn knob until pitot light burns never turn into fill

Instructions

Motor Shaft Seal are

Lever

Door liner

Water Leaks

806565

806863

807042

806898

DIV 22 Source 587 Part Noo